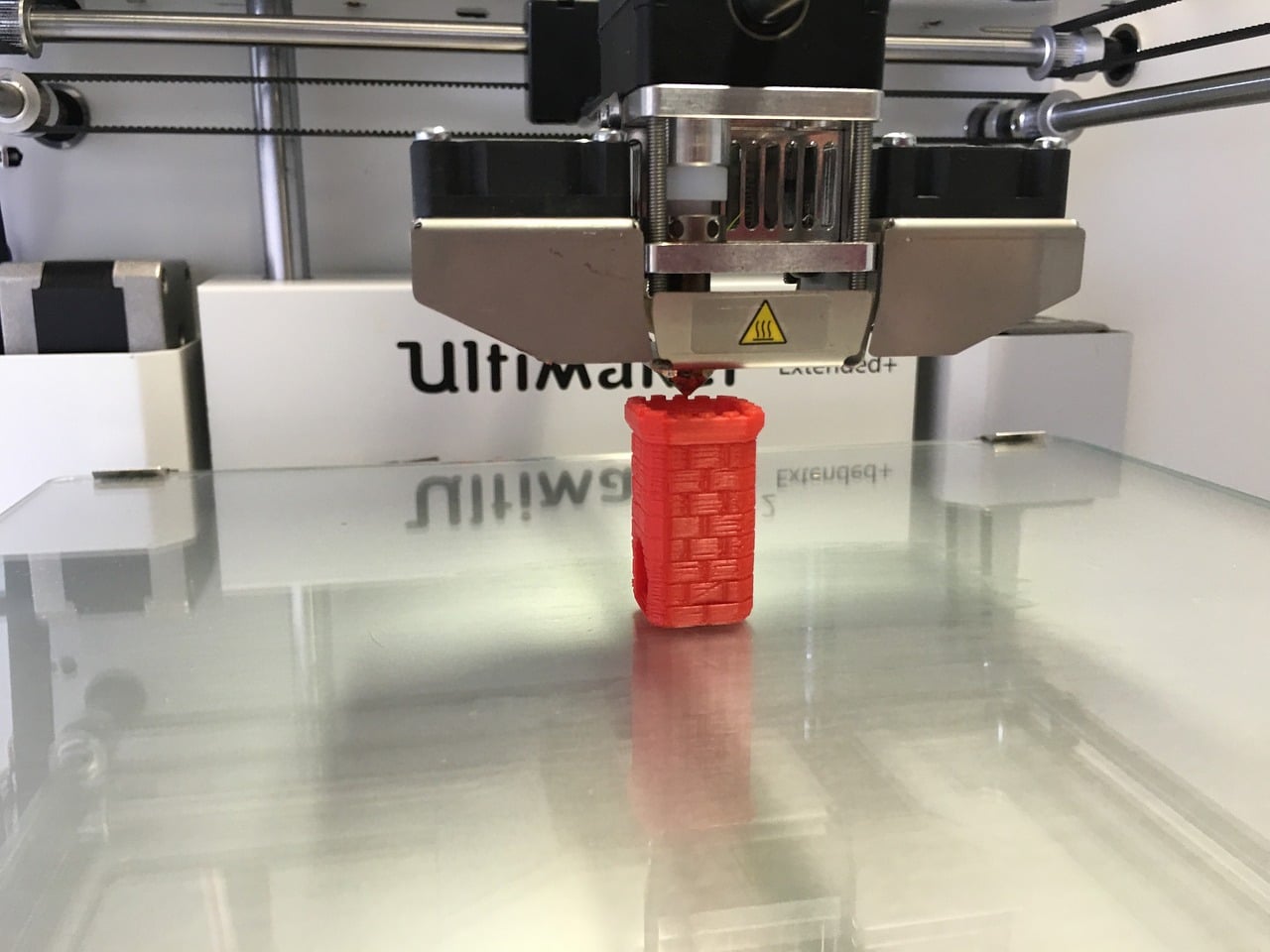

People aren’t just using 3D printers for small-scale art projects anymore.

Nowadays, folks are harnessing the full power of this technology to build cars, assist in crime forensics, replace appliance parts, and even construct homes.

Since the price of a newly built home is higher than ever – especially with skyrocketing mortgage rates – people are looking for new ways to revamp the house they live in. Thanks to 3D printing, home renovations just became a whole lot cooler.

3D Printing for House Construction

Though portions of entire houses can be 3D printed, using this technology to aid in the construction of your home is a much more accessible option. Plumbing is one of the primary issues homeowners face during a renovation. Waste drainage pipes can cost you a pretty penny, but 3D printing allows you to make these pipes out of acrylonitrile butadiene styrene (ABS). It is an affordable, flexible material that is commonly used in the plumbing industry, and luckily, a 3D printer can manipulate this material well.

HVAC repairs are another nearly unavoidable expense homeowners are confronted with during the renovation process. Companies like Daikin Industries are continuously finding ways to help 3D printing address these issues. Recently, Daikin has been experimenting with ways to use perfluoroalkoxy (PFA) plastic to produce essential HVAC parts, which proved to be an even more effective option over other materials, like neoprene and fluorinated ethylene propylene (FEP).

Along with finding affordable solutions, people are often looking for sustainable, health-conscious building materials when renovating or repairing their homes. This includes cleaning the entire renovation area with eco-friendly products. First, you should tackle any surfaces and walls. Thoroughly wipe down tables and chairs with plant-based products free of sulfates and bleach. Then, you should mop and vacuum the floors, clearing the area of pet dander, dirt, and other debris.

After you’ve tackled the basics, protect your floors with biodegradable plastic or tarp. You’ll likely be adjusting things a lot, especially if you’re putting together 3D-printed furniture or installing shelving, for example. In addition, use health-conscious cleaning supplies to prep your renovation area. You’ll already be saturating the area with toxins during the renovation process, so if you clean the area before or afterward, your lungs, pets, and children will thank you later.

Using 3D Printing to Design Your Home

Designing a home is a costly endeavor. This is largely because sturdy furniture isn’t cheap, especially if you want to give your home a bespoke, custom feel. With 3D printing, you can slash your furniture budget in half, creating incredible pieces that reflect your personality and enhance your home. A 3D printer can help you create functional items like:

- Chairs;

- Coffee tables;

- Ceiling light fixtures;

- Side tables;

- Headboards;

- Bed frames.

Using a 3D printer is a versatile experience that allows you to toy with multiple types of materials to create your furniture. This can include material types like polycarbonate, acrylic styrene acrylonitrile (ASA), nylon, steel, and more. One of the most popular furniture-building materials in 3D printing is PLA, known as polylactic acid. Design firms such as Dubai-based NYXO Studio have created stunning 3D printed pieces out of PLA, showing that this avenue of furniture construction can be just as luxurious as it is industrial.

3D printing is perfect for creating one-of-a-kind decor that will elicit gasps from your guests. Create busts of your favorite characters, intricate vases, and paperweights designed after your beloved dog. Go the extra mile and develop interactive wall art, like a topographic map of your hometown.

However, if you’re thinking about stretching your 3D printing creativity to the e-commerce realm, there are some rules to be aware of. Many prominent businesses will prevent you from using the likeness of their intellectual property to gain a profit. So, if you’re particularly good at making Mickey Mouse-themed side tables, maybe keep that project to yourself.

3D Printing Renovation and Home Organization Tools

When renovating a home, staying organized is the best way to stick to your original timeline and remain on budget. This means developing a great way to keep track of all your tools to ensure a safe working environment. Luckily, 3D printing can help you create items that can keep you organized and safe.

A simple but useful item you can make with a 3D printer is a cable hook. Keeping your wires in one place instead of in a tangled mess on the floor reduces fire hazards and allows for swift cleanup at the end of the day.

Speaking of electrical dangers, one common issue people encounter is the risks that uncovered outlets bring. Living at home during renovations means going about your everyday activities potentially exposed to unfinished wiring or harmful tools. Not only do 3D-printed outlet covers prevent accidental paint flecks, but they also prevent children from sticking their fingers where they don’t belong.

Where Creativity Meets Convenience

When using 3D printing outside of a passion project, don’t be afraid to have a little fun with it. The process requires experimentation in many ways, and using your 3D printer for home renovations will give you a sense of accomplishment every time you open your dresser or even flush your toilet.

By implementing sustainable, non-toxic materials and researching the most durable options for your evolving home, you’ll find 3D printing to be a useful renovation option for most of your household needs.

It’s puzzling when you say one “can slash your furniture budget in half” but the cited ArchDaily article lists only bespoke design firms. Only the “Reform Lounge Chair Wood” lists a retail price: a premium USD$2K (converted from SEK.) Besides that, I think only a dozen or so pieces pictured have been produced. Nothing based in Dubai will ever be cheaper than an imported mass produced item, or even a domestic handmade piece. I really want 3DP furniture and objects in my house, but my only success was printing the Bits&Parts “KIDS MAKER CHAIR 19” with hundreds of hours or printing, assembling, and finishing. It’s all too bespoke to be affordable.