Charles R. Goulding and Warren Buzzell look at the innovations in 3D printing that have assisted esports.

Esports, or electronic sports, is a form of competition played via video games. The most common video game genres associated with esports are fighting, battle royale, multiplayer online battle arena (MOBA), first-person shooters, and card games. The esports industry is rapidly growing, and according to Rolling Stone, the global esports market is expected to generate nearly US$2B in revenue in 2022. This would be a US$1B increase from 2021.

As of 2022, there are over 21,000 active esports professionals. These professionals and streamers play up to 10 hours daily and perform around 500-600 repetitive action moves per minute. Studies have shown that esports players commonly experience hand pain, eye fatigue, back or neck pain, and wrist pain. Our previous article, Gaming Chairs That Sit Well With 3D Printing, analyzed one application of 3D printing to improve health-related issues incurred from gaming.

Esports-Related Injuries and 3D Printed Solutions

Analogous to traditional sports, esports is both physically and mentally draining as well as taxing on the body. The following are common esports-related injuries: eye strain, lower back pain, carpal tunnel syndrome, neck pain, tenosynovitis, cubital tunnel syndrome, and sciatica.

As esports and video games have become more popular, we will continue to see an increase in these injuries. Most injuries come from staring at the screen for excessive periods or from repetitive motions made by the fingers, shoulders, and hands over long periods.

For some unlucky esports athletes, these injuries result in missed events, surgery, and early retirement. However, contemporary technology–such as 3D printing–has shown great promise in remedying and preventing these injuries.

For example, researchers have conducted studies to analyze the feasibility of an ulnar groove plasty operation guided by a 3D printing technique to treat moderate to severe cubital tunnel syndrome. Cubital tunnel syndrome is a peripheral nerve compression syndrome. It is an irritation or injury of the ulnar nerve in the cubital tunnel at the elbow. The research team collected and utilized preoperative CT image data to develop a personalized “trial model” of the ulnar nerve groove via 3D printing. The trial model guided the procedure to ensure surgical precision and accuracy.

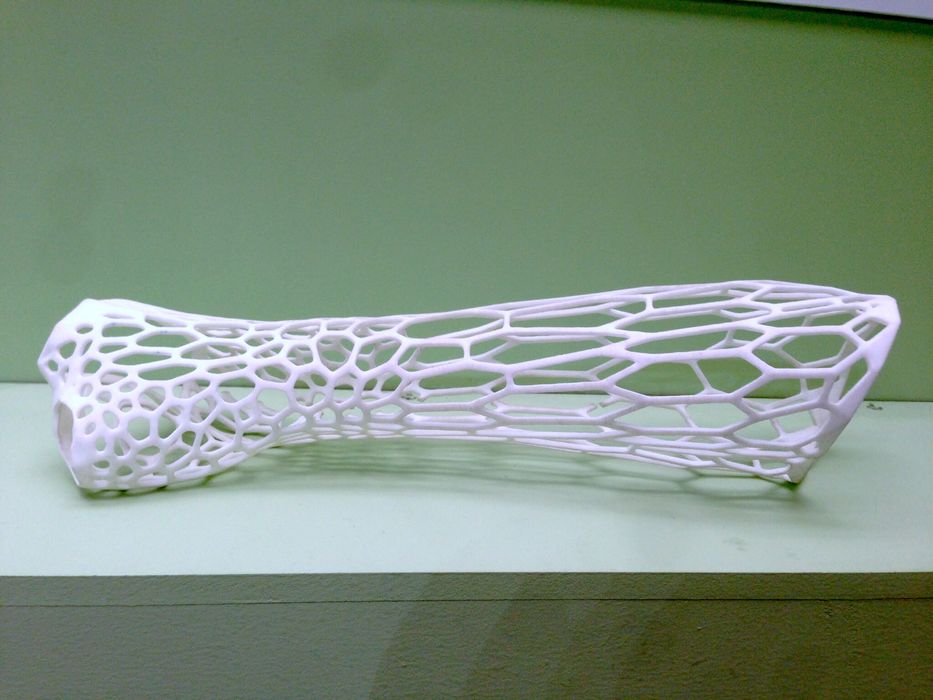

Assistive technology, such as carpal tunnel splints and attachable armrests, are also being 3D printed. These 3D printed assistive devices enable people to wear more personalized devices and increase their comfort at their gaming desks. For example, computer-aided designed splints were 3D printed and evaluated at Morriston Hospital in Swansea, Wales. The developers retrieved and utilized 3D scans of a patient’s arms to 3D print the splints. Prototype models of the patient’s arms were also taken to ensure a perfect fit. Specialists at the hospital tested the splint on a significant range of injuries and patients. 3D printing assistive technology and medical devices are rapidly growing due to the ability to quickly and inexpensively develop and evaluate patient-specific equipment.

3D Printing Gaming Equipment

In addition to integrating 3D printing technology for surgery, innovators have also utilized the technology to develop more custom and ergonomically friendly gaming equipment, including controllers, mouses, keyboards, chairs, etc.

UNYQ, a prosthetic designer, collaborated with IKEA to design and develop ergonomic and customizable 3D printed gaming chairs. As mentioned in our previous article, UNYQ has been working with IKEA to be at the forefront of accessible and affordable ergonomic designs and concepts.

Computer mouses are also 3D printed for their design, ergonomics, and customization. 3D printing technology enables the creation of more custom-made designs and more ergonomically fitted computer mouses due to their ability to be designed to a person’s hand. Additional advantages of 3D printed mouses, as well as other computer equipment, include cost-effectiveness, customization freedom, less waste production, and risk reduction.

The design and development of 3D printed mouses, keyboards, chairs, and other gaming equipment are qualifying activities for the R&D tax credit.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes, and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing, and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating or testing prototypes or for final production, 3D printing is a strong indicator that R&D Credit-eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Leaving A Mark On Esports

3D printing is fun, cost-efficient, and enables the development of fully customizable parts. Whether it be parts for surgery and injury remediation or mouses, keyboards, and gaming chairs–3D printing technology has the potential to leave a significant impact on the esports industry. Innovators are finding unique ways to incorporate this technology to assist surgeons with surgeries as well as to develop custom-fitting assistive technology to quickly and inexpensively remedy issues.

Companies and consumers alike are also working to develop 3D printed gaming equipment. Millennials have already shown a high demand for customizable and unique 3D printed gaming equipment due to their contemporary designs and uniqueness. Companies must continue innovating and increasing their collaborative efforts in this rapidly growing environment to further bridge the pipeline between esports and 3D printing.