The Ceramics Expo returned for 2021, and we were on-site in Cleveland for a look at 3D printing at the in-person event.

First, a caveat: I did not register for the event as media, but rather attended in my new role as the Director of DEI Initiatives at Women in 3D Printing. For that reason, I didn’t do my usual media event routine of tightly scheduled interviews and so have a somewhat different take from this visit.

Everything about the visit was different, anyway, as this was my first in-person trade show since RAPID + TCT 2019, as I was on maternity leave for Formnext 2019, returning to work just ahead of the first shutdowns in 2020. I’ll have more impressions of just what a return to in-person industry events looks like in practice soon — but for now: technology.

Ceramics Expo

The official description reads:

“Ceramics Expo makes a long-awaited return this summer. Located in the heart of downtown Cleveland, Ohio, The Huntington will open its doors to 2,000+ attendees and 220+ leading suppliers & manufacturers from across the technical ceramic supply chain!

At the free-to-attend conference in the hall, 30+ expert speakers will share insights into the latest developments in applications and manufacturing of technical ceramics and the critical role that they will play in ‘enabling a clean, efficient and electrified future’.

Don’t miss this unique opportunity [to] source new materials, components and technologies, gain a 360° view of the ceramic materials market, and make new business connections via our dedicated B2B meetings service.”

Working with founding partner The American Ceramic Society, the Ceramics Expo is a major draw for technical professionals throughout the ceramics supply chain. Materials, tooling, handling, engineering, academia, manufacturing — additive manufacturing; among the 220+ exhibitors there was plenty to see.

Ceramic 3D Printing

Naturally, I gravitated towards the 3D printing on display. The opening Exhibitor + VIP Networking Night ahead of the conference seemed thin on 3D printing, though I appreciated conversations with exhibitors across various sectors, several with interest in the technology. The first day of the event, dedicated to Sustainability & Innovation, lacked additive manufacturing on the conference schedule, so I stayed back in my office. Organizers shared a look:

For day two, centered around Materials & Processing, I planned to spend a full day at the conference and on the show floor.

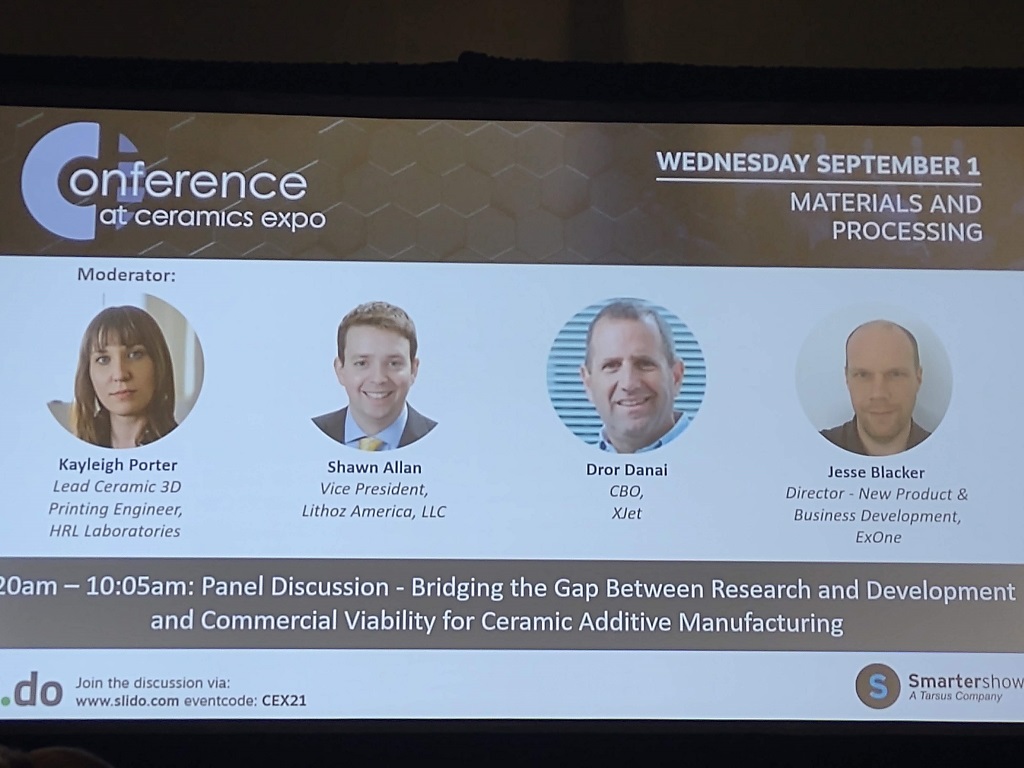

Day two opened with a panel discussion entitled “Bridging the Gap Between Research and Development and Commercial Viability for Ceramic Additive Manufacturing.” It was a wonderful way to kick off the day, as the discussion highlighted the complex geometries that 3D printing enables with advanced ceramic materials — and how those capabilities are moving out of labs and into commercialization.

Moderator Kayleigh Porter, Lead Ceramic 3D Printing Engineer, HRL Laboratories, led the conversation with panelists Shawn Allan, Vice President, Lithoz America, LLC; Dror Danai, CBO, XJet; and Jesse Blacker, Director – New Product & Business Development, ExOne. These well-known companies have seen some of the highest-profile use cases in 3D printed ceramics to date, each using different technologies.

Among the markets highlighted for end-use parts were medical, aerospace, defense, and 5G technologies. Each of these areas requires highly detailed parts made exactly to spec with well-understood materials properties that can perform reliably and predictably. Questions from attendees tended to focus on advantages of 3D printing over traditional technologies as well as different handling requirements for alumina oxide versus non-oxide ceramics, getting into the nitty gritty of materials.

Speaking with Danai after the panel, he noted that this show was an interesting one as visitors come from all over the ceramics field. 3D printing knowledge isn’t nearly so widespread as in some other areas; conversations at this event had to go back to basics to some extent for these advanced 3D printing companies. Post-processing, long held as the “dirty little secret of 3D printing,” was something of an afterthought for visitors — if they didn’t, in some cases, dismiss it entirely.

That mentality was somewhat jarring, Danai noted, as immediately following the show XJet introduced its all-new advanced post-processing system for its ceramic 3D printing capabilities. Announced publicly on September 3, the SMART (Support Material Automatic Removal Technology) station works with the XJet Carmel AM system to automate removal of supports and to eliminate “dependency on operator expertise.” Built using smart algorithms, the SMART station is a big step forward for XJet. And it’s one that went somewhat underappreciated at the Ceramics Expo. The company’s recent commercialization, though, of alumina material was rather more of a hit.

When I ran into Porter later on the exhibit floor, she noted that ceramic 3D printing is something of a “niche within a niche.” That is, 3D printing as an industry is expanding — but ceramics remain something of an area with room for growth. Her background in ceramic arts has come nicely into play for building expertise in engineering with these advanced manufacturing technologies.

Other 3D printing companies exhibiting at the event included 3DCERAM SINTO, Admatec Europe, ExOne, Kyocera, Lithoz, and Showa Denko America. I saw on social media that Tethon3D also had a presence, but didn’t have the good fortune to run into them during the event.

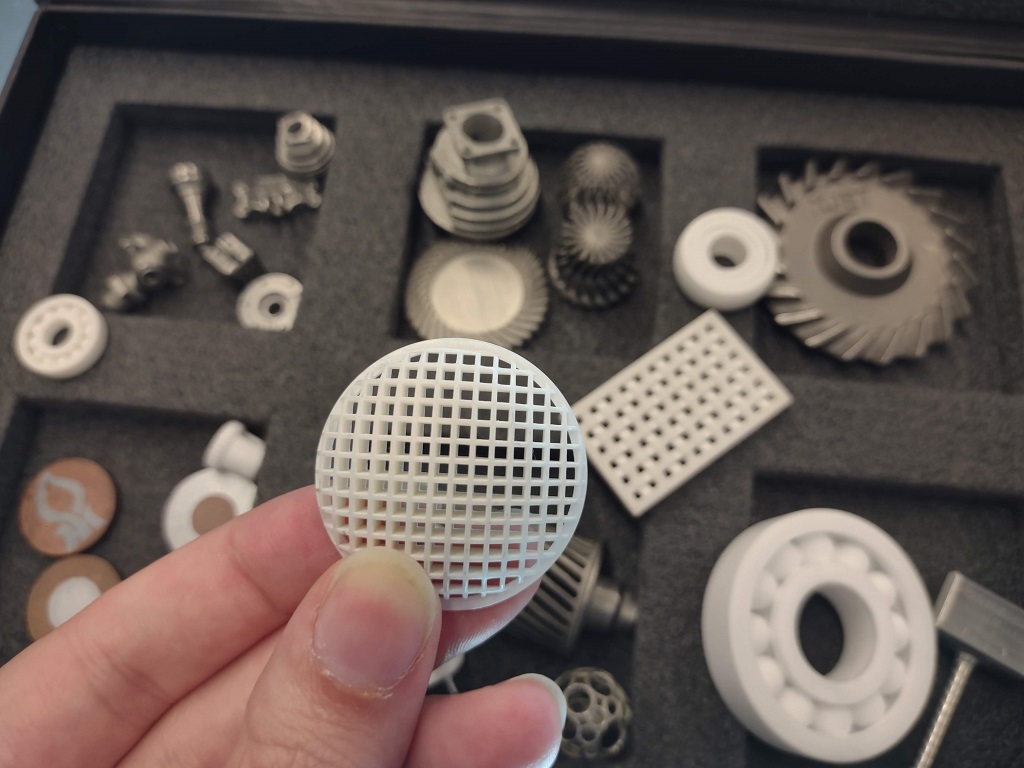

Overall, the 2021 Ceramics Expo was certainly one of the smaller shows I’ve attended in pursuit of 3D printing, especially when it came to actual AM presence. Still, that made it doable in a single day and left room for lengthier conversations. Attendance was down from previous editions, but with ongoing international travel difficulties due to border restrictions — the XJet team were the only international exhibitors I spoke with, and otherwise the farthest traveller I encountered was Porter, in from LA, and several teams from New England — that’s to be expected. It was lovely to be hands-on with industrial 3D printed parts again and to see more industry colleagues and friends in a familiar environment.

Here’s hoping safe, in-person events continue to make their return so we can all enjoy networking, dealmaking, and one another’s company again.

Via Ceramics Expo