Charles R. Goulding and Julia Wallace look at the benefits obtained by the Mayo Clinic as a result of their increased use of 3D printing technology.

The Mayo Clinic has treated millions of patients since its founding in Rochester, Minnesota over 100 years ago as a not-for-profit organization committed to excellence in medicine and patient care. The institution has expanded with major campuses in Arizona, Florida, and the United Kingdom. Doctors and researchers at these centers are on the cutting edge of medical development and care, providing world-class services to patients.

3D Anatomic Modeling

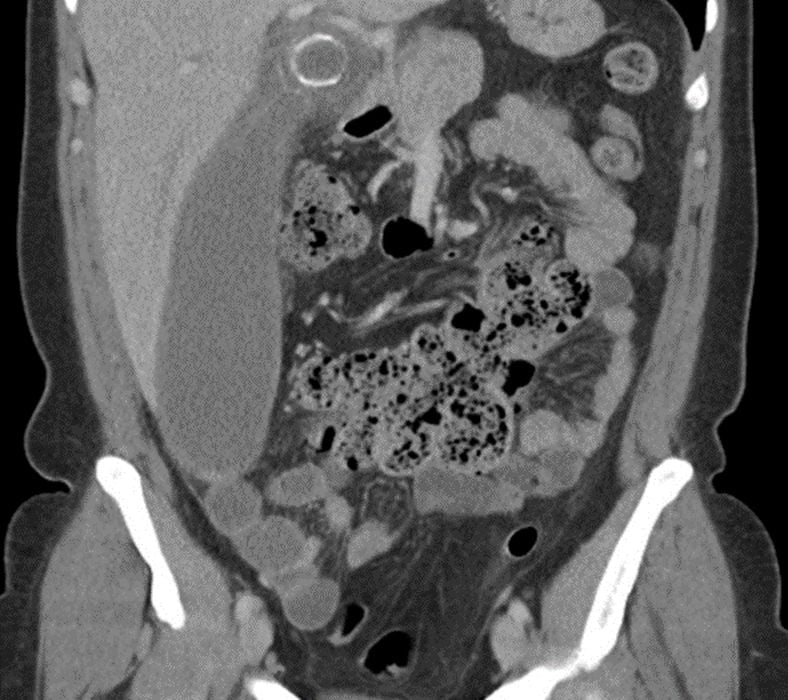

The health system’s 3D anatomic modeling laboratories are used in the radiology department to specialize treatment plans. CT or MRI scans are used to construct a 3D model of whatever organs are to be operated on. Radiologists process the model and color code different types of tissue before 3D printing life-size models of patients’ anatomy. The ink used is often a liquid resin, hardened by UV light.

The ability to examine the internal structure of a patient before performing surgery allows doctors to better understand and plan the difficulties and intricacies of the procedure. The location of tumors, blood vessels, and other internal organs are clear and distinct, reducing the need for exploratory surgery since doctors can see exactly what areas they need to access before beginning a procedure.

This, in turn, allows for faster surgeries and faster recoveries for the patients. Printed models can also be used for educational purposes; they help patients understand what is going on inside of them and what will be done to remedy it, as well as more accurately describe new or uncommon procedures to students and other professionals. Specialists who work in these laboratories have produced over 6,000 models and published about 100 scientific journal articles on 3D atomic modeling.

In 2022, the Mayo Clinic announced that doctors there had performed the first successful entire sternal replacement using a synthetic polyethylene implant in the U.S., and this device had been constructed using 3D printing. Multiple surgeries have utilized custom 3D printed titanium implants.

Countless other surgeries have been aided by 3D printed structures, such as patient-specific cutting guides for use in bone and tissue reconstruction. Research is also facilitated by the use of more accurate modeling, and some researchers are developing technologies where a support system can be 3D printed to allow a subject’s stem cells to attach and grow new tissue.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

The Mayo Clinic is taking full advantage of the benefits of 3D printing in the medical field. Doctors and researchers are using it to improve the lives of current and future patients, advancing the technology to bring care above and beyond anything that has been seen before.