Charles R. Goulding and Julia Wallace look at the use of 3D printing technology in the optical industry.

The History of Bausch and Lomb

One of the largest optics companies in the world, Bausch & Lomb was founded in 1853 in Rochester, NY. It has made countless innovations in lenses and vision improvement throughout the 20th century and continues to develop new technologies, including the development of soft contact lenses as we know them today. The last 15 years have seen some changes in the governance of the company, however.

In 2007, it was taken off of the NYSE when it was acquired by private equity firm Warburg Pincus and was sold again in 2013 to Valeant Pharmaceuticals. In May 2022, Valeant Pharmaceuticals (now Bausch Health), went public, putting Bausch & Lomb back on the NYSE. After reviewing Bausch & Lomb’s patent portfolio, it is unclear if and how often the company uses additive manufacturing in its work, but it is becoming a more standard practice to manufacture contact lenses using 3D printing.

3D Printing Lenses and AR

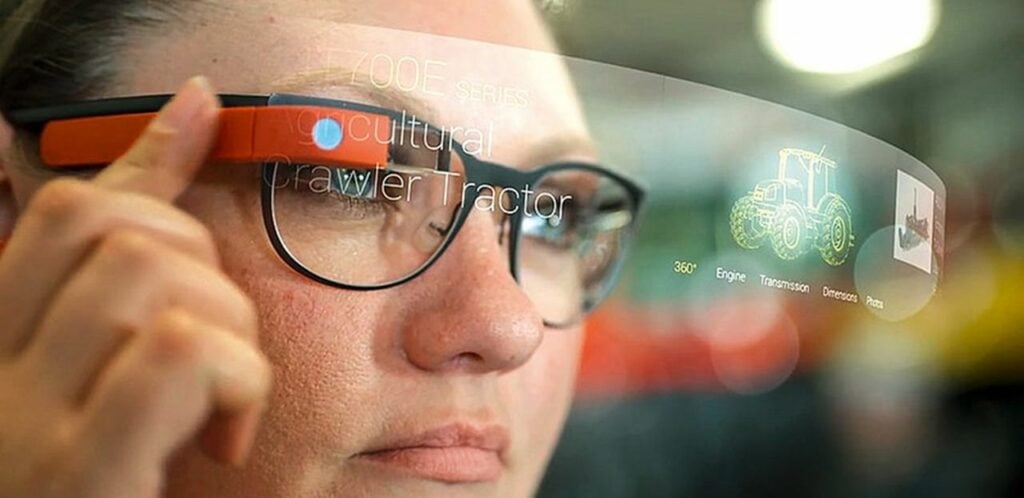

A patent to produce optical lenses using 3D printing was issued in 2015 to Uwe M. Clasen, in which printing is used in conjunction with a laser to provide a custom prescription to patients in need of vision correction. Since then, this technology has come very far. 3D printing is now being used by Luxexcel to create an augmented reality-ready prescription lens.

Using their turnkey solution VisionPlatform, the company prints lenses with layers of acrylic-based resin with extreme precision, tailoring each lens specifically to different prescriptions. Between layers of resin, the printer may also embed smart devices into the lens, using waveguides and LCD screens to provide the user with the AR experience when used.

The incorporation of this technology into the prescription lens eliminates the issue of having to wear two sets of glasses to both correct vision and use AR. It also streamlines the process of creating these glasses. Luxexcel has recently partnered with lens manufacturer Optiswiss, allowing faster production of glasses such as these.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

The progress made in the optical lens industry has been significant in the last century, from the improvement of contact lenses to 3D printing prescription augmented reality glasses, and this progress does not seem to be slowing down. Luxexcel’s partnership with Optiswiss is a promising connection for those enthusiastic about this progress and the accessibility of new technologies.