Charles R. Goulding and Preeti Sulibhavi look at a very new and eco-friendly material that could be used in 3D printing.

There is a fashion trend emerging that combines eco-friendly processes with sustainable materials to produce highly fashionable clothing and accessories.

MycoWorks

A little-known start-up company is turning mushrooms into leather. MycoWorks is a biotechnology company that makes fine leathers from mycelium (mushroom) for applications in luxury fashion, footwear, and beyond. They are currently shipping product and are backed by some of the leading venture capital firms in Silicon Valley.

Their mission is to impact the world with new materials that have superior performance to animal leathers and plastic. Their products currently match or exceed animal leather in their performance, so they are embarking on an aggressive scale-up plan to meet extraordinary customer demand while also continuously innovating to create new materials and methods of manufacturing.

In addition, MycoWorks products are more consistent as animal hides vary depending on the animal it came from. And, because their proprietary process involves so few steps, it has a very low carbon footprint and adverse impact on the environment as well.

This technology is not just sitting in a lab. On the contrary, companies like Hermes and even the auto industry (GM, in particular) are looking to looking to change the sustainability profile of cars as well as modernize the supply chain for these materials as well.

MycoWorks has competition. Bolt Threads, also based in California, is producing leather-like materials from mycelium and is also attracting high-end clients at a staggering rate. Bolt is working with Stella McCartney, Lululemon and Mercedes to create sustainable, yet fashionable materials for their products.

3D Printing & Plant-based Leathers

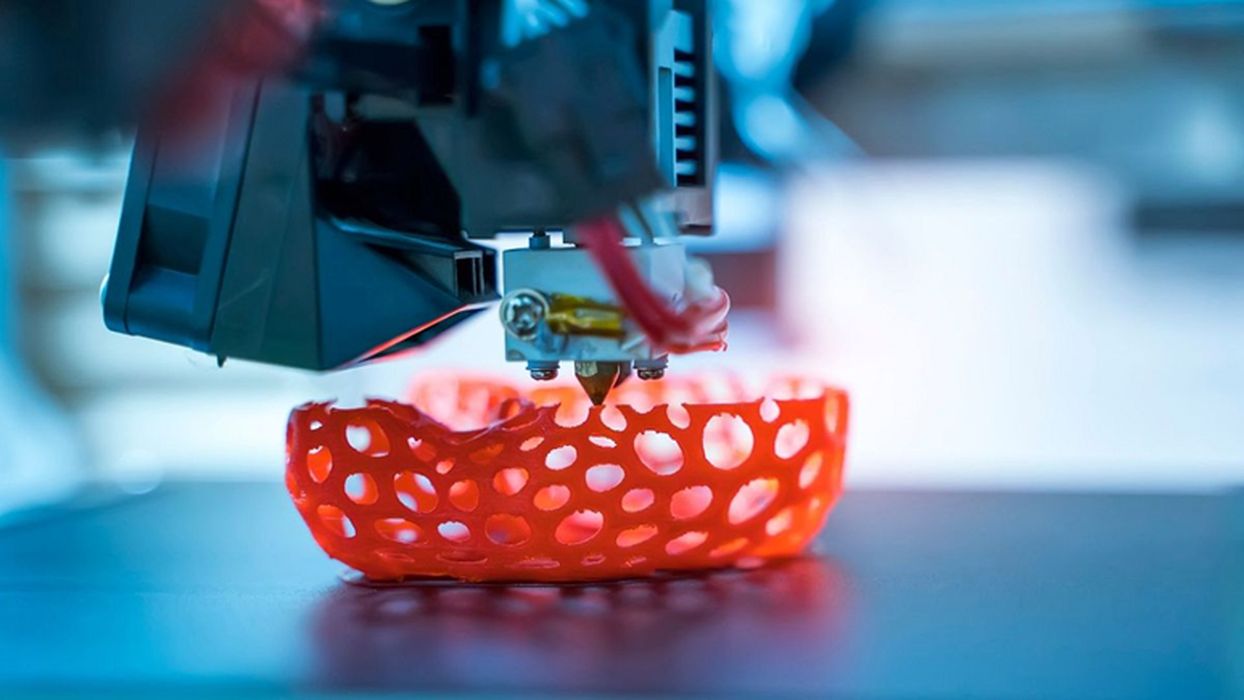

Plant-based leathers are not new to the 3D printing industry. Some big sports brands, including Adidas and Puma, are creating new material technologies for breathable yet sustainable leather, and this includes plant-based leathers (like Mycelium™).

Brands like Uniqlo and Shima Seiki in Japan are using digital fabrication technology to print seamless full garments. Wikifactory is also conjuring up easy-to-fabricate, green materials, whether that’s modular cuttings of samples that allow for minimal cut-offs, sustainable eco-leathers created from waste oranges, or wearable technology accessories.

Fabrics are now being designed without the need for copyrights or patents. The time-to-market rate is massively accelerated. At Wikifactory, they have a project called ‘Resilience’, which is a completely customizable, 3D printed garment at a low cost, where end-users don’t need to sew a single thread to make and tailor a garment with a customized fit.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

Bio-based fabrics are generating a lot of interest. With MycoWorks’ proprietary technology we believe that once they scale up, they could integrate 3D printing technology to enhance their products design, texture and consistency.