An open source photography project has developed a 3D printable lens system, but there’s an interesting implication.

The project in question is “Pixels and Prisms”, a new open source hardware group that has just launched its first product: a 3D printed telephoto lens.

Now, I know what you are thinking: you can’t 3D print optical-quality glass lenses. That’s correct, you cannot easily do so. But you can 3D print the remainder of the lens system, and that’s what this project attempts to do. The actual glass lens is intended to be sourced from commercial providers and then installed in the 3D printed lens system.

The telephoto lens targets the Canon EF mount system, and has a focal length of 163mm. The aperture can range from f/2.5 to f11. The system, although manual, is fully featured. They explain:

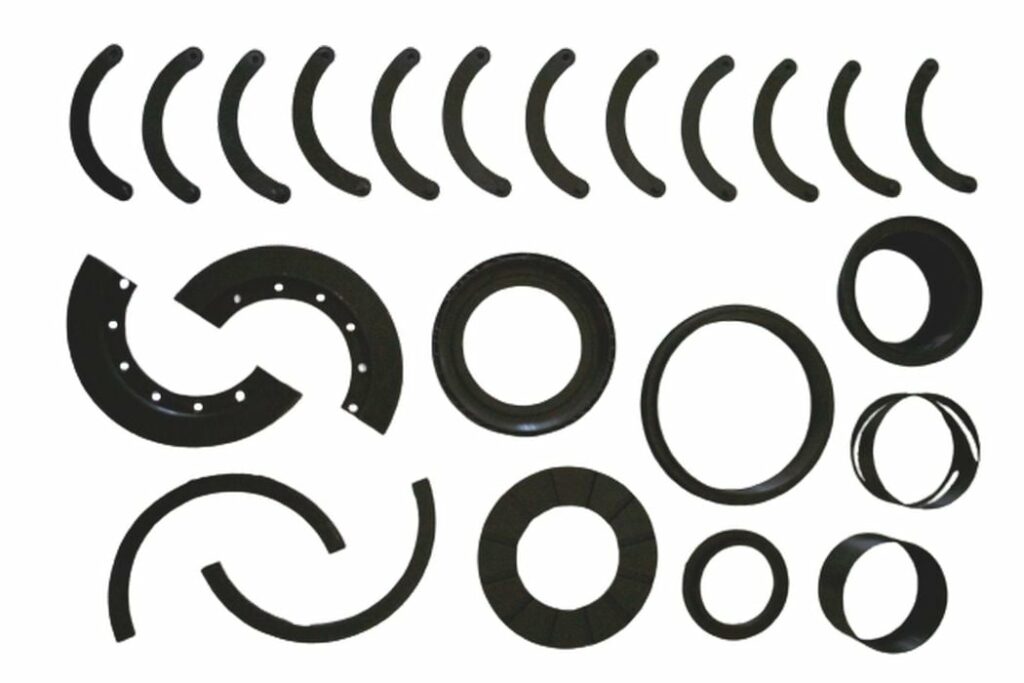

“The optic features all of the functions that you could expect to find in a commercial manual-focus lens. The lens includes 23 significant parts, as well as 15 pegs to facilitate movement.

These include a manual focusing mechanism, which can lock in the fully-extended or fully-retracted positions, and a fully working twelve-blade aperture (many consumer lenses have nine). The latter is a first for a 3D-printed lens designed around a full-frame digital camera system – and the result is smooth bokeh, vibrant sunstars, and crisp results.”

The design (made in Onshape) is apparently sufficiently flexible to allow builders to make customized lens systems with a variety of focal lengths that are not readily available from commercial providers. For example, it is possible to make a 600mm lens for very little cost.

The design of the system involves about two dozen parts that must be 3D printed in black material (so the light doesn’t reflect off the sides during photography). There aren’t even bolts required, as the design uses lengths of filaments as “pegs” to hold things together securely.

The project has published a number of test images taken using the lens system, and they demonstrate a variety of capabilities suitable to even professional photographers.

This is certainly an interesting project for DIY photographers, particularly those on a budget. This allows them to access equipment they might otherwise be able to afford.

But there’s something else I’ve noticed with this project. While there are plenty of 3D printable items available online, this one is for a precision technical tool.

Optical elements are complex devices that easily reveal quality problems in the images produced with them. Bad designs are immediately noticeable. But here we have a device that apparently meets the quality levels and can, in many cases, substitute for a far more expensive commercial product.

That’s a powerful capability, and I’m now wondering how many other supposedly “impossible” precision commercial products could be replaced with inexpensive, yet just as capable, open source DIY products.

Have we broken the “if it’s 3D printed it can’t be that good” barrier?

If there are more projects of this type, this could become a more widespread phenomenon, where buyers can have a significant choice between commercial products and open source equivalents.

That’s a world that could be quite a bit more interesting than today. And a lot less expensive, too.