An RC flyer has performed a very real test of a lightweight 3D printing materials.

Troy McMillan is an expert on RC aircraft; he makes and flies them, highlighting his adventures on his YouTube channel. He’s explained how to build, paint and test many different types of RC aircraft, from a miniature DC-3 to gliders to bush planes.

RC aircraft are not a new thing, and there are traditional techniques for making them. In recent years we’ve seen a shift towards 3D printing as a means to 3D print some RC aircraft components.

Due to the weight of 3D printed parts, which sometimes must be printed robustly with plenty of infill to ensure strength, they have generally been used sparingly in RC aircraft designs. That’s because in flight, weight is everything.

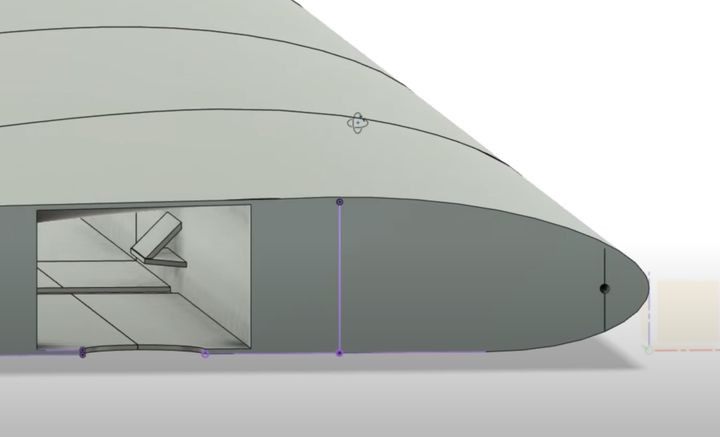

McMillan recently performed a fascinating test: he built three different wings for test on one of his RC aircraft:

- A standard foam wing made in the traditional manner

- A 3D printed wing made from PLA material

- A 3D printed wing made from colorFabb’s LW-PLA

For those not familiar with LW-PLA, it’s perhaps the most ingenious 3D printer filament on the market: It is designed to slightly foam at extrusion temperatures. The idea is to print structures that have embedded bubbles. This increases the volume of the extrusion, but also lightens the weight of the print, hence the “LW” in the product name.

Apparently you can vary the amount of foaming by tweaking the extrusion temperature. YouTuber Stefan Hermann experimented with this idea on one of his recent videos. Hermann used colorFabb’s Varioshore TPU, a flexible equivalent of their LW-PLA used in McMillan’s experiment, which foams in a similar manner. colorFabb produces an ASA version of the foaming material as well.

The two 60” (152cm) wings were 3D printed from the same 3D design, so they were identical except for the print material.

McMillan’s experiment showed clearly that a fully functional 3D printed wing was far lighter if made in LW-PLA rather than conventional PLA. In fact, the fully instrumented wings were 600g for the PLA and only 372g for the LW-PLA. Meanwhile, the traditional foam wing was 332g, only 40g less than the LW-PLA wing.

McMillan then flew each of the wings by installing them on the test RC aircraft. The most interesting part was the flight of the PLA wing, as its far heavier weight was dramatically noticeable: the plane took far longer to take off, and tipped upon landing because its wheels could not take the weight.

Meanwhile, the LW-PLA wing sailed through the sky almost identical to the original foam wing. This experiment clearly showed the utility of LW-PLA as an RC aircraft material for far more components. If it works as a wing, then it can work for almost everything else.

McMillan said:

“This is going to change the game for 3D printed airplanes.”

This experiment demonstrates not only the valuable properties of LW-PLA, but also shows how a change in 3D print material can dramatically affect usage. This new material has effectively opened up a new market for 3D printing that could not exist previously.

That’s why materials are so critical to the growth of 3D printing.

Via YouTube