This month’s community support selection is the 3DP4ME Project in Jordan.

Fabbaloo: Can you provide a bit of background on when and how the project was started? What was the trigger? What happened in the early days?

3DP4ME: “Our founder, Jason, always had a desire to serve people’s real human needs, so after studying Arabic, he began connecting with people all over Jordan who were working with those with physical challenges. During that time he met Andrew, a Dutch monk, the Director of the Institute for the Deaf in Jordan, and the Chairman of World Wide Hearing (Switzerland). He had lived in the Middle East for over 40 years by that point and had helped provide thousands of hearing aids to children and adults in the Middle East, including 2000 Syrian refugees living in Jordan. Jason soon found an opportunity to volunteer with Andrew doing projects. It was with him that Jason saw the amazing transformation a hearing aid could have on a person’s life, especially a child’s. And it was with Andrew that Jason witnessed the intricate and laborious process that went into fashioning hearing aid molds for their clients.

All the while Jason had been searching for innovative technologies that could add value to the Jordanian economy. For motivation he started watching Stanford’s Technology Ventures Program (STVP), eCorner entrepreneur videos — probably 30-40 of them — trying to siphon all the wisdom he could from others’ start-up successes and failures. Jason was especially inspired by Guy Kawasaki (author, original Apple employee) and Tina Seelig (Stanford, Professor of the Practice).

Then, in early 2014, after watching a story with Not impossible Labs (Mick Ebeling) on CNN about a young boy from South Sudan who got a 3D printed arm that changed his life, Jason got inspired by all the possibilities 3D printing could provide! He was sure it could be a key to impacting lives in Jordan. An idea started to blossom.

Knowing almost nothing about 3D printing at that point, Jason began searching for 3D printed solutions to the needs in Jordan. He read scores of articles and watched scores of inspiring videos about innovative 3D projects. One day he stumbled upon one called, A Leg That Fits (by 3D Systems).

He was so moved by it that afterward he cold-called the 3D printing experts from the video, Gregor Ash and Mike Fanning, and asked if they would coach him along his research journey. They agreed and have been advisors ever since!

In July 2015, he visited a 3D Systems reseller in the Netherlands to learn more in person, and in May 2016, he visited Gregor and Mike in Nova Scotia, Canada at their offices with Thinking Robot Studios. They provided Jason some hands-on training with 3D printing and 3D scanning technologies and shared their insights about the Additive Manufacturing (AM) industry and their vision for the future.

As Jason was still learning, Andrew provoked him to consider bringing a new 3D scan/print solution for the hearing impaired in the Middle East. He explained some of the challenges and quoted this statistic from the World Health Organization (WHO): ‘In developing countries, less than 3% of people who need a hearing aid are thought to have one.’ (WHO report, 2013).

That meant 97% of those whose lives could be changed by a simple hearing aid did not have access, and that deeply disturbed Jason. Antiquated ear molds labs, the laborious process of creating a fitted mold, and the cost were among the many reasons for the problem, and there was very little being done to help solve the problem.

Jason decided then and there that he wanted to use 3D printing technology to help restore people’s hearing. In December 2015, Andrew agreed to partner in the effort to provide 12,000 hearing aids to Syrian refugees and low-income Jordanians.

In September 2016 he met Eric Gamble, an audiologist working in Germany who had already been using the Asiga 3D printer to masterfully create the ear molds to be attached to hearing aids for those with auditory impairment. He agreed to share his expertise with me and did most of it via do-it-yourself videos that helped me get my mind around all the equipment and technology necessary to launch a similar project.

Jason tried to take his idea to various NGOs in Jordan, but, unfortunately, it didn’t fit into any of their goals. In the end, Jason realized he would have to launch a new nonprofit organization if he wanted to help meet the growing need for the hearing impaired in the Middle East, especially considering all the war-related hearing traumas. So he did, and called it 3DP4ME (3D printing for ME/’MiddleEast’).

Of course, Jason needed to raise money and set up a legal structure to launch the project, so he started the process of registering a nonprofit in the US. Little did he know then all the hurdles that he would have to jump through!

In order to keep learning, Jason became a podcast junky. He listened to nonprofit professionals to share their stories and learned from their experiences. He reached out to many nonprofit founders directly and asked for advice, and each person gave a unique perspective into the challenges and opportunities of running a nonprofit organization. Their wisdom was gold to him. Eventually, Jason recruited the board members and built a team of amazing volunteers, people with high character, committed to the mission.

We incorporated 3DP4ME in California in May 2016, and then we set out to get IRS nonprofit status. After working on the detailed IRS application and submitting it for approval, we finally got it our 501(c)3 nonprofit status in August 2017. Then things started to pick up momentum.

After a year of trying to contact Dr. Brian Fligor of Lantos Technologies who brought to market a new 3D Ear Scanner, Jason finally reached him! He knew that the revolutionary 3D Ear Scanner could provide us a phenomenal service delivery model with the mobile 3D Ear Scan, to the cloud, to real-time 3D printing of the earmold in a lab. Dr. Brian agreed to help us.

3DP4ME was also able to get commitments and discounts from all the major Audiology vendors: Asiga, Detax, and Cyfex software. Then we secured a commitment from Markus Stratmann, the 3D printing Audiology expert at DETAX, to come to Jordan and help us launch our first pilot project, to show proof of concept on the new service delivery model. We also got our first major PR breakthrough with the LA Times in November 2018. From the Jordan side, Andrew introduced Jason to his Highness Jordanian Prince Mired Raad Zeid Al- Hussein, who is the Head of the Higher Council for the Affairs of Persons with Disabilities, and he was favorable towards our project.

Since 2016 working from Jordan to startup 3DP4ME in California has had its massive challenges, especially because of the ten-hour time difference. In addition to working normal daytime hours, Jason often worked from 9 pm until 1 am Jordan time, to get things done. It’s hard not being able to see people face-to-face.

Andrew retired from the Institute around March of 2018. Afterwards, he dedicated more of his time towards advising 3DP4ME.

Our 3DP4ME pro-bono attorney, Theodore Lee, has worked tirelessly to help us set up a branch in Jordan. There have been many hurdles to overcome and lots of legal red tape to disentangle. In 2019, the Jordanian government required us to complete a two-year financial audit in California, which the state of CA only requires once you go over $2,000,000 dollars a year in donations. We had only raised $50,000, but we were still required to do it!

After completing the audit on September 6, 2019. We submitted all our documents to the US State Department and then the Jordanian consulate in Washington D.C. Upon approval in the US, we shipped the documents to Jordan, where we then started our official registration process with the Ministry of Industry and Trade. 3DP4ME was approved as an NGO by the Jordanian Government on July 7, 2020.

Jason’s advisor and friend, Andrew passed away on Oct 1st, 2020. His legacy still lives on!

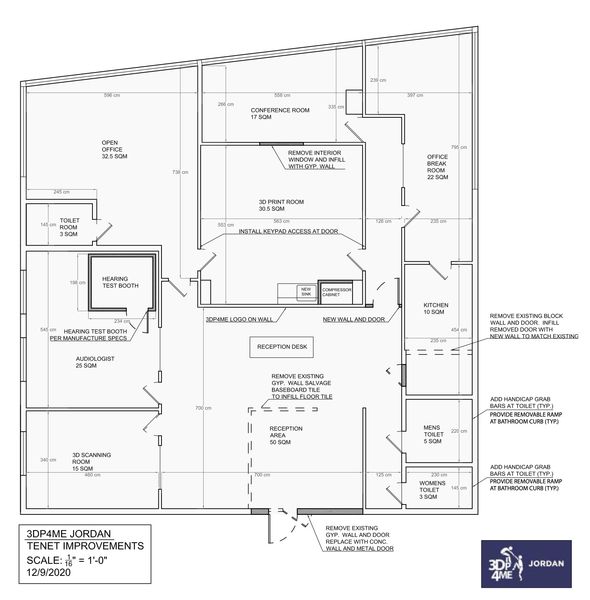

On December 19th 2020, we signed a lease on a new office space. It’s been a significant catalyst for 3DP4ME! We are finalizing our vocational license, completing our bank account setup, and starting our office tenant improvements.

We are preparing to ship all our technology and equipment, and hire skilled and passionate staff. We want to train up our staff with the best coaches from our vendor partners. Then we will run our pilot in Jordan, to show the new service delivery model in a developing country, with the mobile 3D ear scan and 3D printing to provide hearing aids. Dr. Brian Fligor (Lantos Technologies consultant), Markus Stratmann (DETAX materials, 3D printing expert on ear molds), will partner with us in the pilot, and we will film it in order to show it to larger potential funders.

In the Jordanian market, hearing aid costs $1000 USD per device. We plan to provide hearing aids at a lower than market cost, while keeping a sustainable model.

Overall the years and through all the challenges, our team has kept anchored in my deep-rooted desire to restore people’s hearing. Our founder, Jason, reminds us about all the lives we will impact, especially kids whose potential will burst open the moment they receive a hearing aid, fitted with a 3DP4ME mold. That’s what it’s all about — changing lives and serving real human needs with practical 3D printing.”

Fabbaloo: What are the key successes thus far?

3DP4ME: “As a nonprofit tech start-up, we are building momentum. Getting approved in Jordan as a charity on July 7th of 2020: It took a long time to overcome many legal hurdles in the US & Jordan, in order to become operational.

Our amazing community of generous donors and advocates. Incredible team, we are so proud of our team. Words can’t say enough about their commitment to impact.

Our industry industry supporters, including: Asiga — Graham Turner, significant cost discount on 3D printer purchase; Cyfex Software — Rolf Koch, donation; DETAX — Markus Stratmann, 3D printing expertise with ear molds; Erik de Bruijn — Ultimaker BV; and Raidy — donation of a S5 Pro 3D printer.

Our new office in Jordan is a big catalyst for us, heading into 2021.

Just a few weeks ago, a couple of our team members in Jordan flew to Boston to be trained by Dr. Brian Fligor for 3 days using the Lantos Technologies 3D ear scanner. Both members of the team, were able to gain a strong competency with the scanner.”

Fabbaloo: How big is the team, where are they located? Are you looking for more participants?

3DP4ME: “We have a team of 23 volunteers and advisors, and we have a (New) Additive Manufacturing Expert Council:

Rush LaSelle — Jabil Additive

Peter Mayr — Technical University of Munich (TUM)

Erik de Bruijn — Co-Founder, Ultimaker (Now Stekker.app)

Ben Ferrar — Carpenter Additive

Mirek Classen — BigRep

Florian Reichle — Trinckle Software

Dr. Cora Lüders-Theuerkauf — Mobility Goes Additive (MGA)

Once we have the funds we plan to hire three Jordanian employees for our pilot: Administrator; 3D printing engineer; and an Audiologist.”

Fabbaloo: What tools do you use for communication, printing, CAD, etc?

3DP4ME: “Internally we use Slack, Asana, Google docs. Externally we use Virtuous CRM to communicate with our constituents.

Overall, we are working towards an end-to-end custom solution, for a much broader range of assistive devices. The team from Hack 4 Impact, is helping us to design a customized ‘ERP like’ software solution. It will pull together all the pieces of the digital workflow through APIs.

We plan to have two 3D printers on the ground, in the coming months: Asiga ‘Max’, 3D Printer (ear molds), Ultimaker, S5 Pro, 3D Printer (R&D). For CAD we use Cyfex software for earmold design with Trinckle software.”

Fabbaloo: What are your next steps for the future? What is the end goal?

3DP4ME: “As we start working with community partners to identify our first 50 clients in need — who will receive exams and be fitted with a customized hearing aid solutions as part of the pilot — is so incredibly exciting.

Our vision is to create a state-of-the-art advanced manufacturing facility providing scalable solutions for a range of assistive devices to those in need in the Middle East, starting with the Hearing Express Project to deliver hearing aid solutions.

The goal of our Hearing Express Project was to provide 12,000 hearing aids to those in need: 4,000 individuals who are in need of mono-lateral fitting (1/3) and 4,000 individuals who are in need of bi-lateral fitting (2/3). Starting with our Pilot in 2021 where we will fit 50 recruited clients to be fitted with customized solutions – we will expand to full service.

We are so excited about the possibilities for 2021, building on the interest and momentum that has seen us through the past 6-years, to being able to work with those in need and start making a real impact. Your support at this point will assist us in the purchase of equipment and supplies, to hire and train new staff, and successfully run our pilot!

Please consider a donation. Thank You for Your Support. We Could Not Do This Without You!”

Each month Fabbaloo selects a worthy non-profit project or activity contributing to 3D printing and provides not only a published story on the project, but also free advertising on our well-read pages. If your project would like to take part in the program, please fill out our application form here.

Via 3DP4ME