Charles R. Goulding and Preeti Sulibhavi look at how 3D printing could play a big role in a new strategy in Tulsa, Oklahoma.

For economic development purposes, Tulsa has decided to focus on some high-growth technology areas, and mobility is one of them. The mobility strategy is comprehensive and includes walking and biking, autonomous cars, and drones. Their drone strategy has gained momentum with the Federal government award of US$38.2M.

Oklahoma State University’s Oklahoma Aerospace Institute for Research and Education (OAIRE) has received two federal grants to expand its reach and impact in the development of Advanced Air Mobility (AAM).

The OSU grants are awarded by the US Economic Development Administration as part of a US$38.2M award to the Tulsa Regional Advanced Mobility (TRAM) Corridor to create a hub for research, development and production in the burgeoning field of advanced mobility — the next intersection point between the aerospace industry and intelligence.

The funding will be used to create the LaunchPad Center of Advanced Air Mobility at the Helmerich Research Center on the OSU-Tulsa campus and support ongoing research activities at OSU (i.e., the NASA University Leadership Initiative led by OSU) and the recent agreement between the state governments of Oklahoma and Arkansas to develop Advanced Mobility pilot programs across the border. The new center will focus on research and development of drone technology and urban air mobility such as urban “air taxis.”

Jennifer Hankins, head of partnerships with Tulsa Innovation Labs, said the new agreement is “an important step towards realizing our vision and transforming Tulsa into an inclusive, thriving city of the future.”

In addition, when storms knock out roads and bridges, one of the biggest challenges for emergency managers is getting supplies into the affected areas. The research at OSU is looking to meet that challenge through the air.

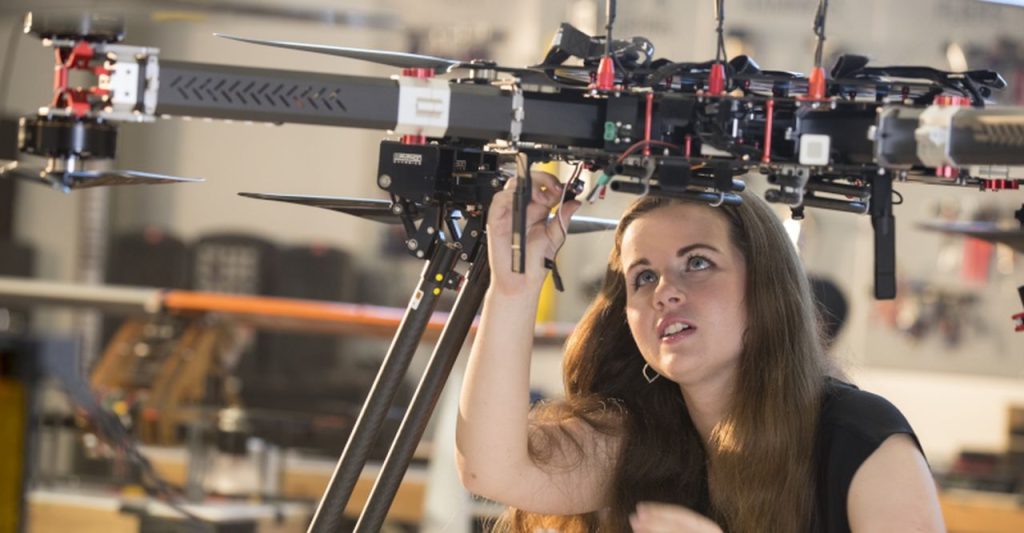

OSU’s Unmanned System Research Institute has teamed up with Stillwater startup MaxQ to demonstrate the life-saving capabilities of drone technology. The project combines OSU’s drone expertise with MaxQ’s proprietary technology to improve delivery times for medicine and other crucial supplies. Time can mean the difference between life and death in a medical emergency. Drones can circumvent infrastructure damage and help save lives.

MaxQ’s revolutionary transport coolers can store blood and medicine in a lightweight, thermally insulated package that monitors the state of sensitive payloads. Drones with MaxQ technology could rapidly deliver medicine in a system that would be especially effective in hard-struck areas.

“It’s a fantastic partnership,” he said. “OSU’s Unmanned System Research Institute has access to several different drone platforms, and this partnership has allowed us to marry our technology with unmanned delivery systems. I think this is just the beginning of our partnership, and we look forward to continuing to work with USRI to develop this platform and make it possible to save lives.”

So it is no surprise that we see the US$38.2M in grant money being used for drone design and development an opportunity for the 3D printing industry to be a part of the advanced air mobility program.

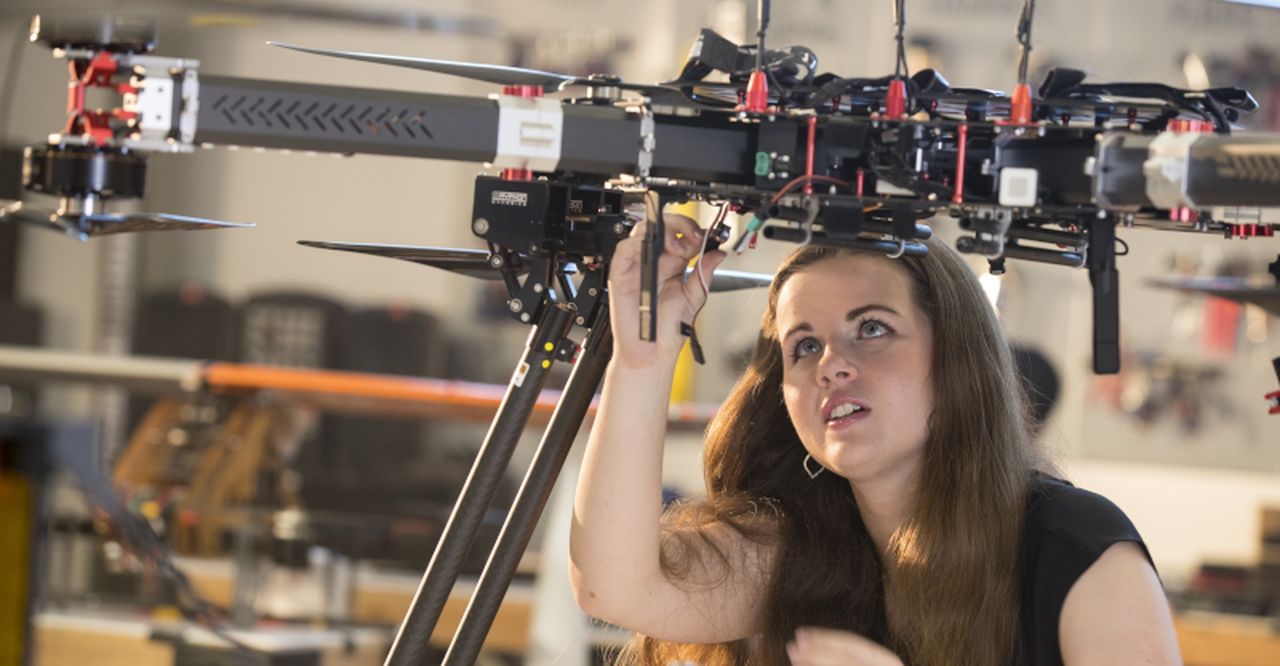

Whether it is the quadcopter frame, flight controller boards, propellors, camera, landing gear, or parts of the brush motors, 3D printers can help drones achieve higher quality designs and improved functionality.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

Drones can go where there is a lack of infrastructure, damage or conditions not conducive to human travel. We see 3D printing playing a vital role in creating drones with the grant money Tulsa recently received.