1000 Kelvin has integrated their powerful software into Autodesk Fusion 360.

The software in question is AMAIZE, the company’s “AI Copilot” for metal 3D printing. The idea is that 3D models printed directly from CAD tend to fail.

The problem is that the extreme temperatures used in metal 3D printing tend to cause distortions throughout the print job. Metal expands as it is heated, and this expansion travels along the geometry of the model. The result can be distortions in the geometry, or in the worst cases, cracks due to the stressed encountered during cooling.

It’s possible to compensate for these effects by tweaking the geometry of the model before printing. A region might be shifted slightly in position, so that when cooled it will “land” where it is supposed to be. That’s an extraordinarily simplified case: in real life these distortions build on each other in a complex cascade of movement.

Creating these compensations are unbelievably complex. They change with every new geometry, and it’s effectively impossible to manually identify and create them.

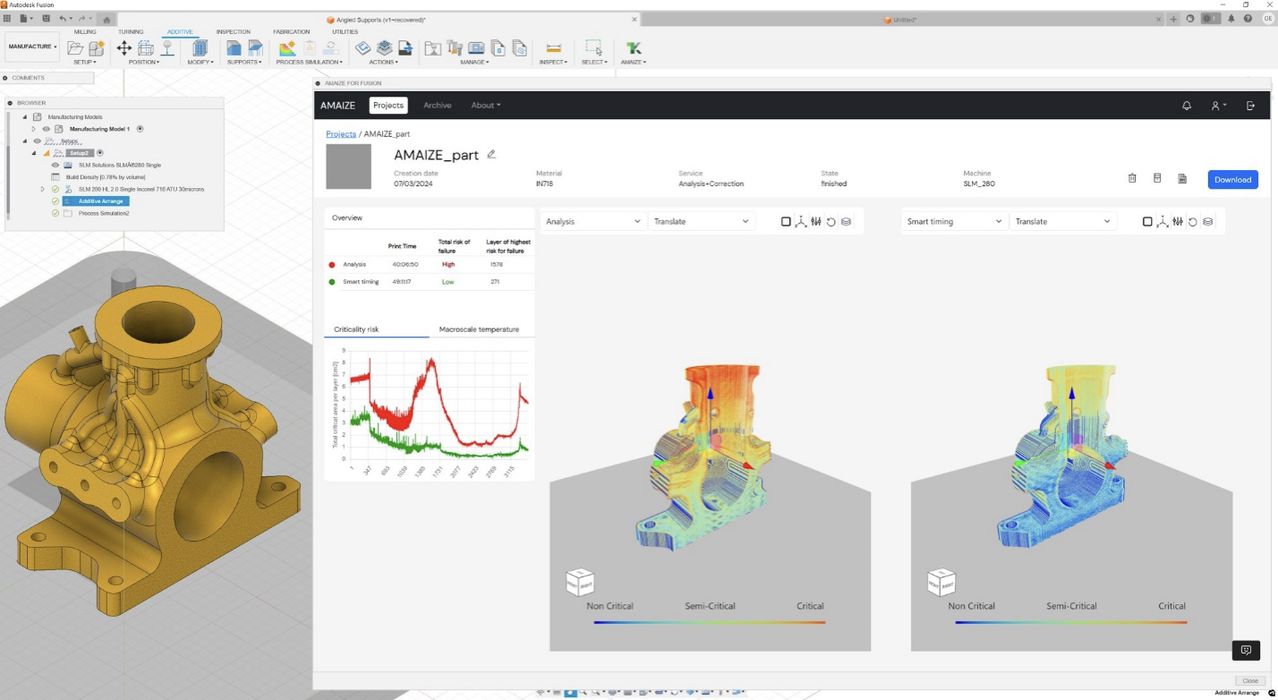

That’s what 1000 Kelvin’s AMAIZE will do automatically. It takes as input a normal CAD file, and then performs an AI-powered analysis on the geometry. It will identify all the geometry tweaks required to successfully print the item on a specified printer with a selected metal material.

1000 Kelvin explains:

“AMAIZE uses machine learning models informed by physics and manufacturing data to predict design and print issues and output optimal print files that result in successful prints. As a result, engineers using additive manufacturing can eliminate physical trial and error cycles, and handle more complex parts which would otherwise require extensive and time-consuming design iterations.”

This sounds very good, but there are a couple of steps involved: create the 3D model; export it; import it to AMAIZE; process; export; send to 3D printer.

This is now simplified significantly by 1000 Kelvin’s new Autodesk Fusion 360 plug-in. The plug-in directly integrates AMAIZE into Fusion 360, so that a model can be processed within the CAD tool.

Consider it like this: a model is designed, and then as a final step, it’s “cleaned” by AMAIZE before sending to the 3D printer.

This is very likely the first of many steps to be taken by 1000 Kelvin to make their AI copilot much more accessible to the 3D print community. I suspect they will announce integrations with other CAD tools, as well as announcing support for additional materials and metal 3D printers.

Via 1000 Kelvin