![The MilleBot, a 3D printer inside a shipping container [Source: Mille]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08c038a0bf.jpg)

An interesting partnership was announced this week, joining hardware and software elements to form a powerful combination.

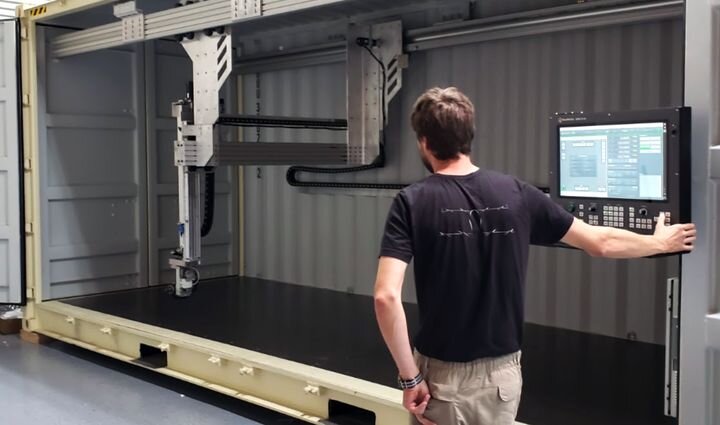

The two parties here are well-known to this publication. The hardware side of the equation is Mille, a Florida-based company that has devised a way to produce 3D printers in standard shipping containers. The large size of the container means you can have a relatively large-sized 3D printer inside.

The MilleBot 3D Printer

Mille has developed ways to allow these container-based 3D printers to be highly mobile. They can be transported anywhere, as easily as a shipping container — because they ARE shipping containers. This means it is possible to very quickly set up a 3D printing factory literally anywhere by dropping a MilleBot onsite.

The MilleBot can be customized in size by joining adjacent containers together, and can be arranged in arrays. Like any shipping container, the MilleBots can be stacked to create a dense factory-sized 3D printing operation.

3DPrinterOS Cloud

Meanwhile, 3DPrinterOS is a long-time player in the 3D print space, offering a cloud-based operational solution for 3D printers. We reviewed 3DPrinterOS way back in 2014, although back then they addressed the needs of desktop devices; today their main focus is on the industrial and educational markets.

By attaching a “dumb” 3D printer to 3DPrinterOS, it can immediately benefit from a wide variety of sophisticated services available from their cloud network, such as file storage, logging, standardized job slicing, and much more. Their tagline is “Easy 3D Printer Management”.

![3D printer management screen [Source: 3DPrinterOS]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08c03d65b9.jpg)

This combination makes a great deal of sense, as it essentially makes the MilleBots “smart” as soon as they are hooked up to 3DPrinterOS. It also provides a way for customers to properly manage an array of MilleBots that have been set up as a temporary factory in the field, for instance.

Remote 3D Printing Network

But there’s one question I had about this arrangement: how do these mobile 3D printer factories actually communicate with the cloud? By definition dropping a shipping container in a parking lot doesn’t mean it will have any connectivity at all. Normally 3D printers are installed in sites that already have networks established, and you merely plug them in. Not so with the often remotely installed MilleBots.

That’s where the “5G” angle of this announcement comes in. They say:

“MilleBot and 3DPrinterOS’ partnership will focus on creating advanced digital-manufacturing machines with state-of-the-art software supporting a variety of tools, materials, and techniques to build large scale parts in plastic and metals using directed energy deposition. The 5G capability allows customers enough bandwidth to encrypt and monitor the entire end-to-end workflow from a secure web browser, even from a parking lot.

This means that for the first time ever, users can produce and monitor their production factory in real-time anywhere, at any time.”

This partnership is jointly developing a 5G network to enable the machines to communicate with the cloud with little setup involved. That instantly makes the whole notion of “mobile factories” a lot simpler.

Mobile 3D Printing Factories

What can be done with this powerful combination? They have some thoughts:

”This technology has the potential to deeply impact a wide variety of industries. For example, enterprises and the military can start by prototyping a large part as a helicopter or submarine, and instantly push-to-production anywhere on-site in the world. In the logistics sector, crates are proven technology that can be shipped anywhere in a secure manner and reduce logistics costs. The new system even has the ability to produce parts en route with batteries and 5G-connected solutions ready for making replacement parts. The system was even tested with intermittent 2G connections, and without fail, the platform has been proven to work all around the world.”

Not everyone will need an on-demand, remote 3D printing factory, but I suspect those that do, do so with much interest. For them the alternative would be to manufacture or procure parts from traditional sources and then suffer through a long transportation delay to deliver the parts to the remote area. It’s now possible to overcome those delays, at least for parts truly producible on the MilleBot.

Via IssueWire