![The Dremel CNC [Source: Instructables]](https://fabbaloo.com/wp-content/uploads/2020/05/dremel-cnc_img_5eb08c1759f5b.jpg)

This week’s selection is the impressive 3D Printed Dremel CNC project by 19-year old Nikodem Bartnik.

This project is interesting because it physically marries the two manufacturing domains, additive and subtractive. 3D printed parts are used to build a device that CNC mills soft solid materials like wood or foam in three axes.

There’s a reason this is called the 3D Printed “Dremel” CNC, and that’s because the core of the CNC mill is literally a Dremel, the familiar hand-held utility tool. It can accept a wide variety of bits for many different purposes, and is therefore ideal to be the spindle of the CNC mill in this project.

![Many of the parts required to assemble the Dremel CNC [Source: Instructables]](https://fabbaloo.com/wp-content/uploads/2020/05/dremel-cnc-parts_img_5eb08c17bc2fd.jpg)

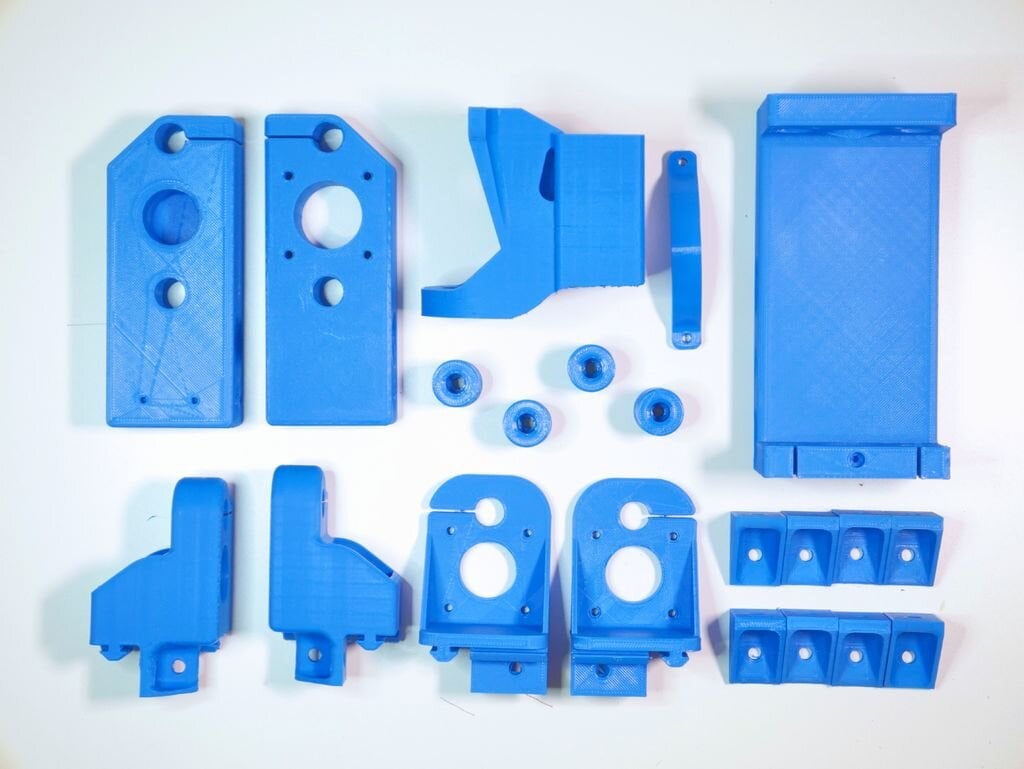

As you might imagine, there are plenty of parts required to complete this project, some of which are 3D printed. Fortunately, Bartnik provides everything you need to know about obtaining or making the required parts.

![The 3D printed parts for the Dremel CNC [Source: Instructables]](https://fabbaloo.com/wp-content/uploads/2020/05/dremel-cnc-3dp-parts_img_5eb08c1822f6f.jpg)

In addition to the hardware components required, there is a solid software chain that must also be assembled. On the controller board, an Arduino, you must install GBRL, that’s firmware that controls the stepper motors for the motion system. To control the Dremel CNC you’ll need to install CNC.js, an open source package that provides a web based interface for the CNC, and it looks pretty good:

But what do you need to use to generate the GCODE to program the CNC? Bartnik recommends using Autodesk Fusion 360, which can not only be used to design a 3D model for CNC milling, but also to generate the required three-axis GCODE.

It’s not clear how long it will take you to build the entire project, as it depends on your skill level. However, the instructions provided by Bartnik are extensive. The Instructables document is quite complete, and there are no less than six YouTube videos from Bartnik explaining all the gory details.

There’s even a Facebook group dedicated to the project where anyone can join to gain advice and see what others are doing with the device. There’s also several variations available to use the same general machine plan for laser engravers and vinyl cutters. Bartnik does explain how to use the machine as well.

![Sample cuts from the Dremel CNC [Source: Instructables]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08c189aca4.jpg)

What is important to me is that Bartnik dedicates an entire section to the topic of safety, which is actually more important on CNC devices than most 3D printers. Bartnik discusses the problem of flying material, as well as heat and even noise, all of which must be monitored during operations.

For those of you who have interest in making parts using a subtractive process in addition to a 3D printer, this could be a very inexpensive way to do so.

Via Instructables