I’m watching a promotional video from Siemens & EOS and had a thought about 3D print benchmarking.

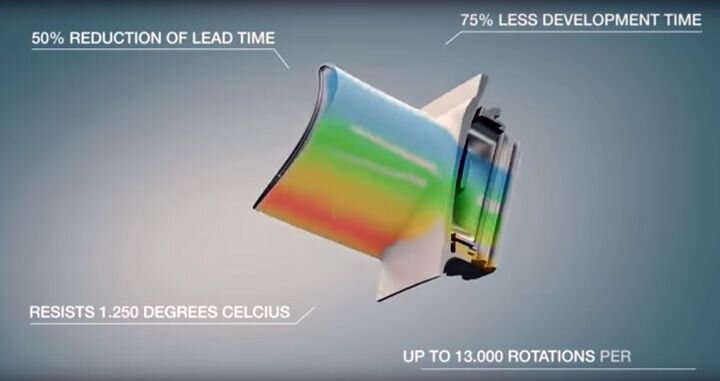

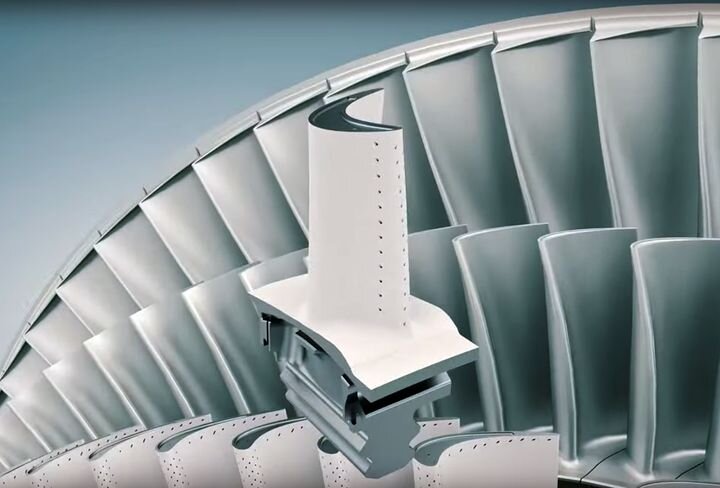

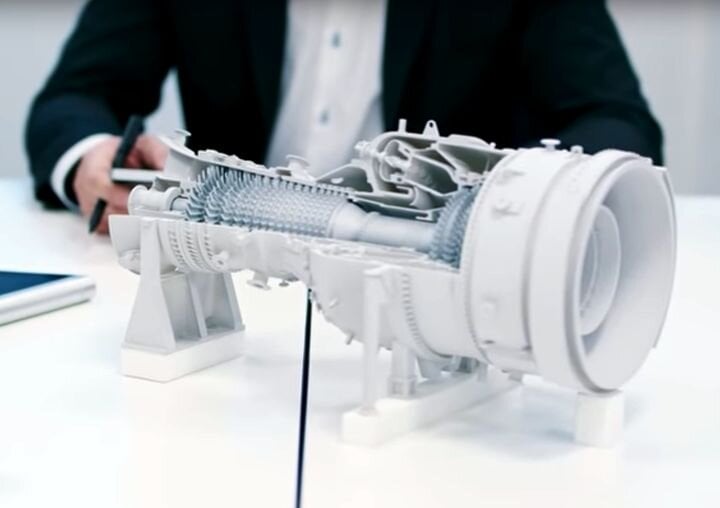

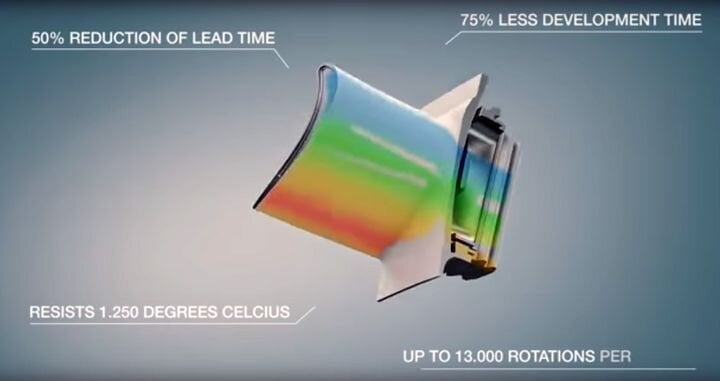

The two-minute video briefly explores how the two companies successfully worked together to design and 3D print production-quality gas turbine blades, which turn out to be quite difficult to produce.

3D Printed Gas Turbine

A gas turbine, if you’re not familiar, accepts a flow of hot gas produced by burning a liquid fuel. The turbine blades are pushed by the flow and produce a rotational force on a rotor that is then used to generate electricity. Gas turbines are typically found in electrical power plants.

At first glance, the tiny turbine blade seems to be a rather simple part, but in fact it is not. It must balance a large number of engineering and production factors to be truly successful. Let’s take a look at some of the challenges involved:

-

It must withstand extreme forces generated by the rapidly spinning rotor

-

It must exist in a very hot gas environment (1250C in this case)

-

It must be extraordinarily reliable, as there are many in a turbine and ALL must not fail

-

It must be as lightweight as possible and employ thin walls

-

It must provide extreme aerodynamic performance

That last point is particularly important, as the efficiency of the turbine is incredibly valuable: if it spins constantly throughout its life, even the slightest variation from optimal will be quite costly.

As well, the part must be reliably producible on designated equipment at an effective cost.

Complex Metal 3D Print

Clearly the successful production of such a part is a great challenge. How much so? In the video, Dr. Markus Seibold, Head of Additive Manufacturing at Siemens Power and Gas said:

“If you can print a turbine blade, you can pretty much print anything.”

And:

“It is one of the most challenging applications for metal additive manufacturing.”

That got me wondering whether this type of object could actually serve as a type of “benchmark” for metal 3D printers, in the same way many other commonly used objects have become standard tests for other types of 3D printers and processes.

Metal 3D Printing Benchmark

While a turbine blade might be vastly more complex than the common #3DBenchy benchmark object, could it serve as a benchmark object for metal 3D printing? I think this could work, particularly if used when evaluating additive manufacturing services or perhaps even when considering the purchase of a device.

However, in this case it is highly unlikely Siemens would release this particular turbine blade design to the world for use as a free benchmark object, as it obviously was a proprietary work for their business. The design is likely a significant advantage to Siemens in their sales of gas turbines.

However, it may be possible for someone to develop a gas turbine blade 3D model that happens to have the right geometric characteristics to taken on the role of a benchmark object, in the same way that #3DBenchy has a number of relevant features for simple benchmarking.

Is there such a benchmark in existence? Or can someone design and release a #Turby?

Via YouTube