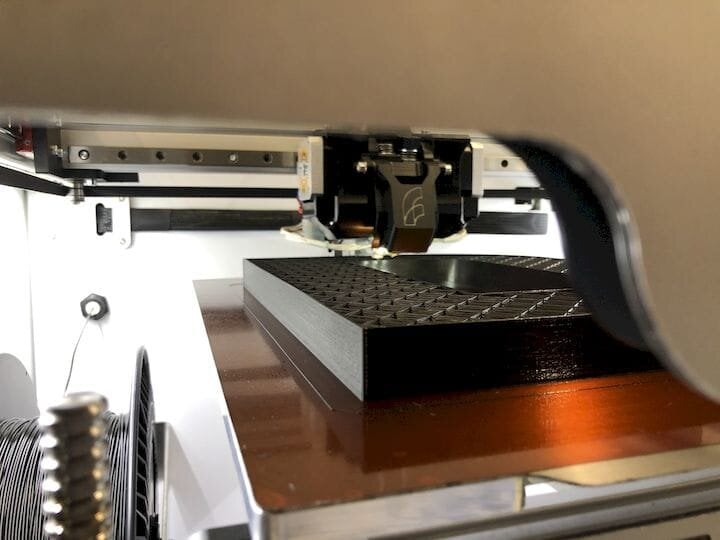

![Printing machine component prototypes [Source: FELIXprinters]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08ff3473b6.jpg) Printing machine component prototypes [Source: FELIXprinters]

Printing machine component prototypes [Source: FELIXprinters]

There are many people and businesses now using 3D print technology worldwide, and we’ve come to know some of the major 3D printing use cases.

But there’s another one that I’ve just realized: food production.

We are all familiar with the typically cited key uses of 3D printing:

-

Rapid product prototyping

-

Personalized dental appliances

-

Low-weight aircraft components

-

Custom medical implants

-

Low-volume production

3D Printing Niches

But there are a few more niches where there actually is a tremendous boost by using 3D printing on a daily basis.

One we recently wrote about was in data centers. Data center use of 3D printing is absolutely not the first thing to come to mind, but as it turns out there is significant need: with constant changes in wiring and equipment, customized cable channels, clamps, guides and other components are required to keep things tidy. By simply designing and 3D printing whatever is required, a data center can easily keep things clean without requiring the expense for pricey commercial equivalents.

Now we’ve heard of another one, courtesy of an interesting case study from FELIXprinters.

Netherlands-based FELIXprinters produces a well-regarded line of filament-powered 3D printers of various sizes. Their equipment is entirely suitable for use by industry, which is their current market target.

One of their clients is Houdijk, a manufacturer of food handling equipment. This is where it gets interesting.

You might think food handling equipment is a relatively tame concept, but in fact it is extraordinarily complicated. Why? Because there are an infinite variety of possible food products. Some may be large, some small, some wet, some dry, some cold, some slippery, some solid, some liquid. You get the idea.

3D Printing Food Handling Equipment

Now imagine designing a machine to “handle food”. You can’t.

Each and every machine has to be specifically designed to meet the particular properties of the food product to be handled. This is the job of Houdijk: to consider carefully the needs of their clients, and in particular the handling functions required to be performed for a specific food product with different properties.

Some of these machines can perform incredibly fast production, with apparently up to 23,000 product operations per minute — that’s about 384 per second! The operations performed could be anything, such as counting, measuring, inspection, or feeding.

This means they literally have to design machines uniquely for every customer request, which apparently involves every possible kind of cookie, biscuit and cracker. And to do so, it turns out they do a great deal of prototyping to make sure their design concepts actually work in the ways intended.

Using FELIXprinters

![3D printing machine prototype components; no, they are not cookies! [Source: FELIXprinters]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08ff372983.jpg) 3D printing machine prototype components; no, they are not cookies! [Source: FELIXprinters]

3D printing machine prototype components; no, they are not cookies! [Source: FELIXprinters]

Their prototyping is done using FELIXprinter equipment, including a pair of Pro 3 printers and a Pro L model. The Pro L model has a build volume of 300 x 400 x 400 mm, allowing Houdijk to produce larger prototype parts for their machine experiments.

This scenario makes a great deal of sense, yet it is not known as a major use case for 3D printing. I’m wondering how many other use cases are still hidden in industry, waiting for someone to realize the benefits of 3D printing.

Via FELIXprinters