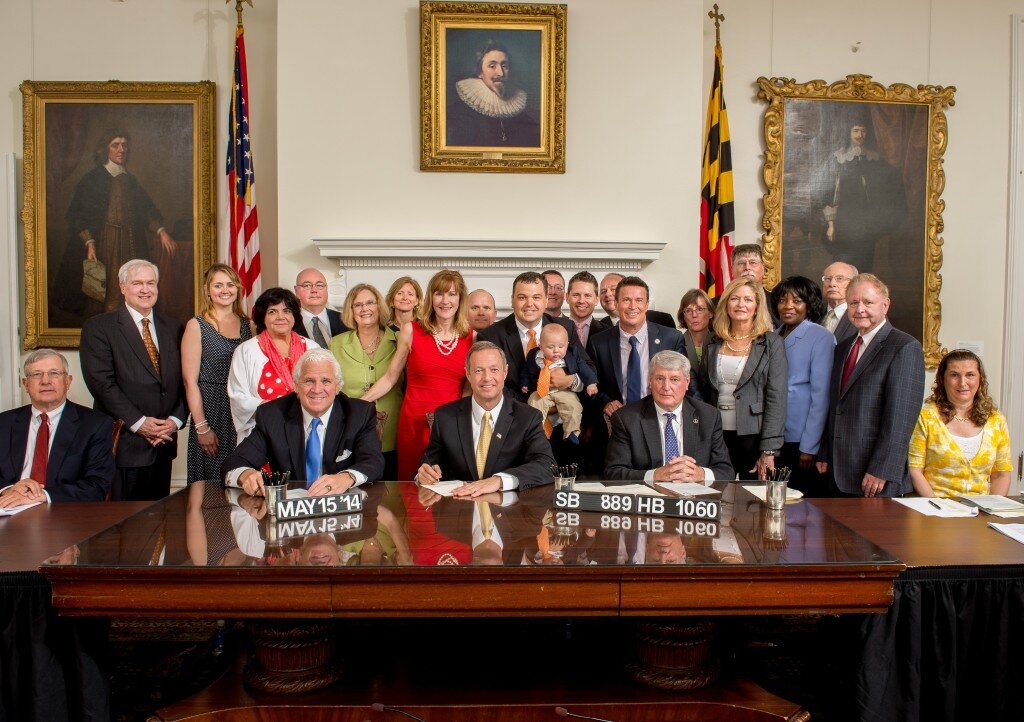

![Maryland legislators creating RAMPMD [Source: RAMPMD]](https://fabbaloo.com/wp-content/uploads/2020/05/SB889-HB1060-1024x722_img_5eb090380d79a.jpg)

Additive manufacturing is not something you simply decide to do. There are a number of skills required before one can undertake serious work with the technology.

And even before that, awareness of the technology and confidence that it can perform useful functions is definitely required. If you don’t believe in AM, it won’t happen.

But given the expected boom in the technology and in particular the radical applications made possible by it, how can a region ignore the technology? What steps could be taken to provide the technology a boost to ensure it does begin soaking into the local manufacturing fabric?

One impressive venture in this regard is the Regional Additive Manufacturing Partnership of Maryland, or “RAMP MD”.

RAMP MD Consortium

It is a consortium formed by the state government. They explain:

“Established by the Maryland General Assembly in 2014, RAMP MD (Regional Additive Manufacturing Partnership of Maryland), is a consortium of private businesses, educational institutions, governmental agencies, and representatives of U.S. Army Aberdeen Proving Ground (APG) that are working together to expand Maryland’s capabilities in additive manufacturing.”

What exactly does RAMP MD do? They say they are:

-

Educating a supporting workforce

-

Providing access to facilities and equipment to manufacture AM products

-

Building the required infrastructure to support the manufacturing base.

Those are precisely the steps one might imagine are needed to provoke use of additive manufacturing technologies. The key seems to be leveraging a quantity of AM equipment based at the US Army Chemical Biological Center in Maryland.

At this center, visitors can make use of AM equipment directly and experience what it can — and cannot — do. This is a key part of the learning experience that businesses might go through on the road to adding AM tech in their operations.

Production AM Costs

Production-level AM is a very expensive proposition, and especially so for metal production. We’ve previously on the extreme expense required to set up and operate a metal additive manufacturing facility and features of a contract manufacturer using additive manufacturing. The issue is not only the cost of the machines and fine metal powder materials, but also the post-processing equipment and air-controlled facility to put it all in.

There’s also the not-insignificant cost of the engineers required to analyze prints and set up the highly complex thermal structures necessary to prevent warping during and after printing.

Imagine being a manager in a manufacturing company and attempting to present a proposal to your boss to create a metal AM capability and trying to explain the huge costs without any experience or examples. It could be suggested to the boss that “amazing designs are possible”, but without any concrete examples, bosses generally won’t understand and might consider the venture a risk not worth taking. Not a good strategy.

A better strategy would be to experiment and learn AM at low cost. Then, actual example designs could be developed and produced on AM equipment. These could be shown to the budget masters to prove the utility and opportunity of the technology. That would certainly have a far greater probability of approval.

That seems to be what Maryland has set up with RAMP MD: a place where experimentation can be done.

In addition to equipment access, RAMP MD also offers educational symposia and even a training program that apparently will generate between 50-100 journeymen/women into the manufacturing sector every year.

Launch AM Support

If you’re in Maryland, this is good news. If you’re not in Maryland, consider whether your region offers such services to the public and businesses? How is your region promoting the use of Additive Manufacturing technologies?

If there isn’t a program to do so, why not help get one started?

Via RAMP MD