![Several different porous materials 3D printed with ip3DP [Source: Royal Society of Chemistry]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09264c720a.jpg)

New research has shown a way to produce microscopic porous structures using 3D printing technology.

Researchers from the Singapore University of Technology and Design wanted to improve methods of fabricating small porous structures, as this type of material is becoming vastly more important. Porous structures are increasingly used for filtration, battery storage, sensors and other applications. Thus being able to make them more effectively is quite important.

Currently microscopic porous structures are developed using different multi-step processes. Often a material is washed away with a solvent to reveal the porous structure. But as you might guess, multiple steps means multiple expenses.

Worse, there are significant geometric limitations in the style of porous structures being fabricated.

There has been some work in this regard in 3D printing already. Some commercial filament offerings propose porous structures by mixing a dissolvable sacrificial material within the filament, such as PVA. This allows a print to be soaked in water after printing to create the porosities as PVA dissolves. There are similar approaches for resin 3D printing, which involve a mix of materials.

The problem with all these is that there is limited controllability of the porous structure itself, and the types of materials available for use are also limited.

The researchers developed a new approach they call immersion precipitation 3D printing, or “ip3DP”. In this approach they developed a special polymer mix that is 3D printed by a syringe mechanism into a non-solvent. Their approach uses a ternary “polymer — solvent — non-solvent” combination to achieve the precipitation.

Essentially, the polymer is mixed with a solvent and that is how the 3D printable solution is prepared and extruded.

The immersion causes precipitation to occur, and this results in solidification when the polymer ink is in contact with the non-solvent.

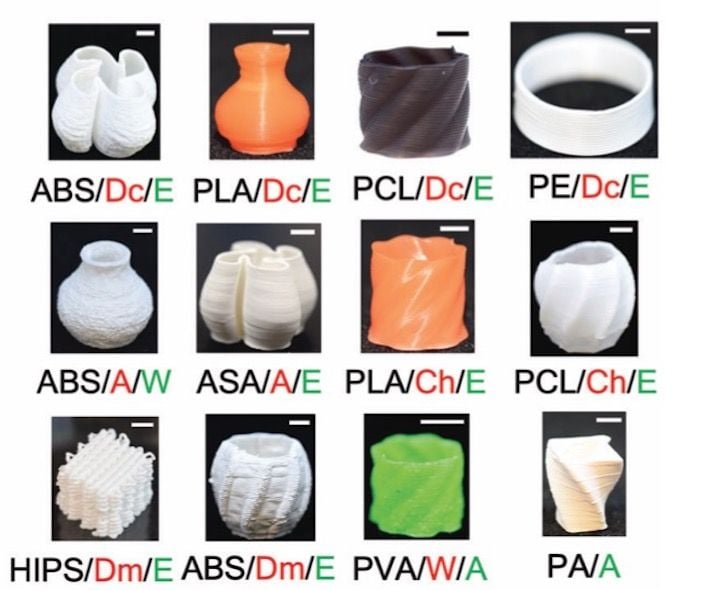

At top you can see an image of porous structures made from various typical 3D printable materials they produced using the ip3DP concept. The labels indicate the material, solvent and non-solvent.

You may notice that these are all different combinations. That’s the key to their approach, as they are able to use different combinations of solvents and non-solvents to be able to match with specific desired materials. This makes their approach quite flexible.

Here we see a microscopic image of the results of one experiment using ABS material:

![Sample 3D print of porous ABS material [Source: Royal Society of Chemistry]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb092652b9c2.jpg)

The researchers examined a number of materials and found they were able to successfully generate complex porous structures with each. This suggests this process could be a viable method for producing porous structures at commercial levels.

If that’s the case, then we may see a new series of ip3DP printers producing industrial quantities of microscopic porous materials for use in many different kinds of applications.

Via Royal Society of Chemistry

A research thesis details the incredibly complex world of volumetric 3D printing. We review the highlights.