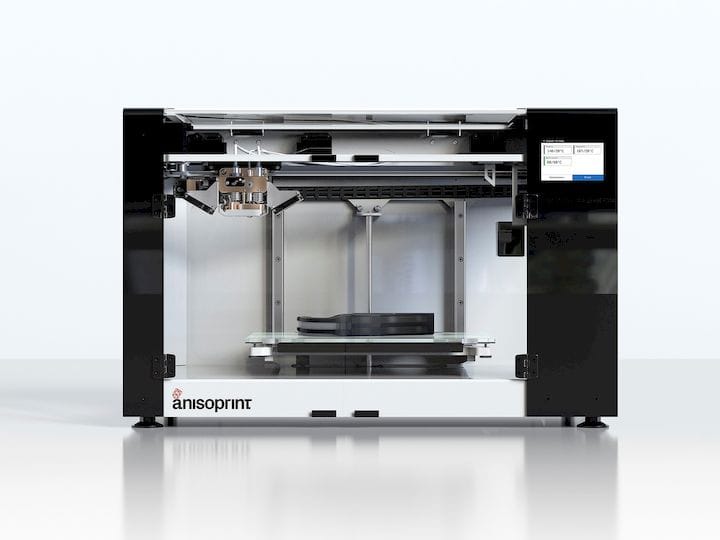

![The Anisoprint Composer continuous carbon fiber 3D printer [Source: Anisoprint]](https://fabbaloo.com/wp-content/uploads/2020/05/AnisoprintComposer_img_5eb09677a8933.jpg)

Anisoprint announced an arrangement that should make their continuous carbon fiber 3D printer even better.

The startup company, which we first encountered in 2017 at Formnext, offered an almost-unique solution: 3D printing continuous carbon fiber in prints. This is very different from the typical “carbon fiber” 3D printing done by other printer manufacturers.

The usual application is to chop up carbon fiber into tiny segments and mix them with a liquid polymer resin, typically PLA or Nylon. Then when 3D printed, the objects are somewhat stronger due to the presence of the small carbon fibers. However, that strength is limited because the fibers are not continuous nor aligned.

Anisoprint takes a different approach, one that we’ve seen only in Markforged equipment elsewhere: 3D print a continuous carbon fiber. This is done by having another deposition tool streaming out the fiber at about the same time as the thermoplastic is extruded. By arranging the fiber to be lain into the print’s structure in appropriate directions, the strength of the print can be vastly increased.

Anisoprint’s new arrangement is an agreement with Malta-based Thought3D. This company produces sophisticated adhesive solutions specifically designed for various 3D print materials under the brand name Magigoo. The benefit to Anisoprint here is that while their machine works very well with PLA, it requires an adhesive solution for other materials such as PETG or ABS.

![The Magigoo 3D printing adhesive solution [Source: Anisoprint]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09678095a5.jpg)

These are engineering materials that might be more applicable for the continuous carbon fiber capabilities of the Anisoprint Composer 3D printer. Thought3D also has solutions for Nylon and Polycarbonate, thus opening up some interesting possibilities for the Anisoprint Composer.

The nature of the collaboration between the two companies is not quite clear yet. It may be that it is simply a bundling deal where Magigoo might be included with the printer. Or it could be a discount for Anisoprint operators. Or it could be a custom-developed adhesive solution uniquely for Anisoprint machines. Or something else. Or a combination of all of the above.

Whatever it turns out to be, this development will make the Anisoprint Composer a more powerful professional 3D printer that will be of increased interest to engineers and product designers.

Via Anisoprint and Thought3D