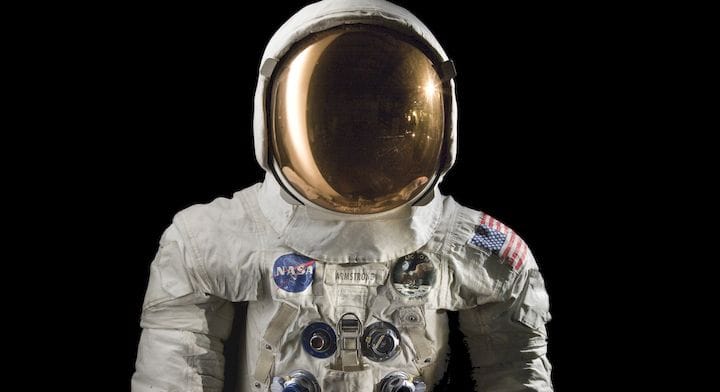

![Neil Armstrong’s actual lunar spacesuit [Source: Smithsonian Institution]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb095093d105.jpg)

The Smithsonian Institution is 3D printing life-size copies of Neil Armstrong.

Well, actually they’re 3D printing his spacesuit, you know, the one that was ON THE MOON. Yes, this organization has plenty of incredible artifacts in their seemingly limitless warehouse, and one of them is Armstrong’s suit.

This spacesuit has been carefully stored since it returned to Earth with Armstrong in July 1969, soon to be exactly 50 years ago. The suit does not include the toe covers, which were left on the lunar surface to save weight heading home, but does include scuffs of actual lunar dust.

To celebrate the half-century anniversary of that incredible event, the Institution decided to bring forward this artifact to the public. While it’s far too precious to ship to multiple locations for public display, they’ve figured out an alternative solution: 3D printing.

The plan is to capture a highly detailed 3D scan of the suit in standing form, and then 3D print several replicas. These will be displayed in 15 different baseball stadiums across the United States.

By chance there is a terrific video from super maker Adam Savage that details the process of scanning and making these incredibly detailed replicas:

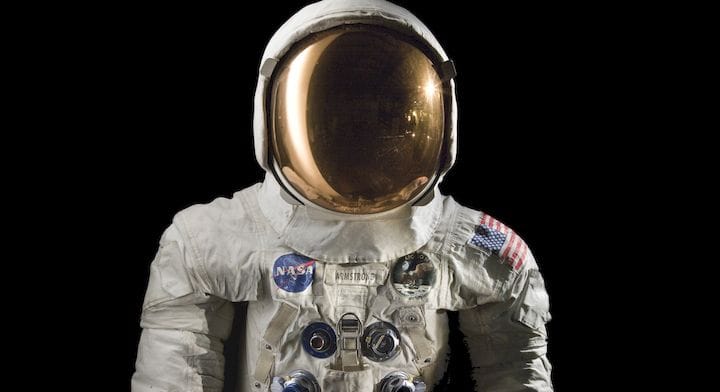

![3D scanning Neil Armstrong’s space suit [Source: YouTube]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0950991940.jpg)

3D Scanning Neil Armstrong’s Spacesuit

The process began with a detailed 3D scan of the original suit, mounted in a standing position. From the looks of the video, it seems they used an Artec 3D Space Spider 3D scanner, which has an accuracy of only 0.5mm and a resolution of 0.1mm. However, the video also explains that multiple scanning methods were used, including a touch probe.

The results were incredible, and comprised 5.3GB of scan data. The cloth stitching was even visible on the scans and subsequent prints. Here you can see the detail obtained on Armstrong’s glove:

![Highly detailed 3D print of a 3D scan of Neil Armstrong’s lunar glove [Source: YouTube]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09509c78ab.jpg)

3D Printing Neil Armstrong

The printing process was also interesting. To make this possible, they divided the entire full-suit 3D scan into a number of segments using CAD tools. Then each part was 3D printed using a voxeljet VX1000 3D printer. Of course, the print jobs were set to fill as much of the build volume as possible, just as one does with any other 3D printer.

![Large 3D print job to produce a full-size replica of Neil Armstrong’s spacesuit [Source: YouTube]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0950a24a91.jpg)

If you’re not familiar with voxeljet’s equipment, they produce large-scale 3D printers capable of making very large objects.

![The voxeljet VX1000 used to 3D print Neil Armstrong’s spacesuit [Source: YouTube]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0950a63d7a.jpg)

The VX1000 device used here, for example, has a massive build volume of 1000 x 600 x 500 mm. This particular device is designed to 3D print in sand or PMMA material for the production of industrial molds.

Rotomolding a voxeljet 3D Print

![Rotomolding a 3D scan of Neil Armstrong’s spacesuit [Source: YouTube]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0950ac16eb.jpg)

And that’s exactly what this project intended: the 3D print was in reality the mold for casting the final replicas. Molding was done in a custom-built rotomold setup, where the mold is continuously spun on multiple axes to slosh the casting material around the edges, but leave a hollow in the center.

Finishing and Painting Neil Armstrong Replica

Once finished, the full-size suit appears with a gray surface, although highly detailed. At that stage the project invoked their finishing team, who sanded the surfaces to appropriate levels, and then painted the surface with realistic colors that matched the actual artifact. They had to ensure the finishing materials were durable, particularly in outdoor environments at baseball parks, where UV light from the sun could strike the replica.

![Painting a replica of Neil Armstrong’s lunar spacesuit [Source: YouTube]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0950b07b58.jpg)

In the end they’ve produced an incredible set of replicas of Neil Armstrong’s lunar spacesuit, and they will enable many thousands to catch a bit of the excitement over the 50th anniversary.

I’ve encountered several 3D models based on celebrities recently and wondered whether this is a good or bad thing, and for whom.