![Build your own CNC machine [Source: Amazon]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb095fc10d92.jpg)

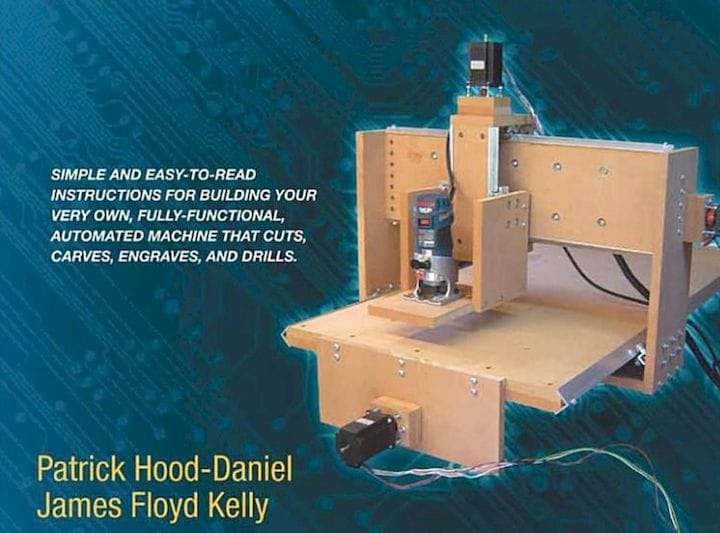

This week’s selection is “Build Your Own CNC Machine” by James Floyd Kelly and Patrick Hood-Daniel.

As you might gather from the title of this book, “Build Your Own CNC Machine” definitely has nothing whatsoever to do with 3D printing. But we strongly suspect many readers will nevertheless find this tome interesting.

The reason we suspect this is due to the interest in multi-tool 3D print devices. For example, recently Snapmaker completed their groundbreaking Kickstarter campaign in which they raised the most money of any tech product in Kickstarter history. One of the reasons they succeeded so dramatically was their unusual multi-tool device, which included a small CNC milling capability.

Therefore those who do 3D printing do have an interest in CNC milling. And why not? Both are powerful making technologies, although their approaches are literally opposite: one is additive and the other is subtractive. You know which is which, of course.

This book should address those CNC urges.

It’s basically a book-long assembly manual for constructing a small CNC machine. The machine is framed with wood — and the book even provides tips for cutting wood for those with less experience.

The machine design is a standard cartesian three-axis unit, equipped with stepper motors for the motion system. The book takes you through building and installing each of the axes of the system.

Mach3 Software

![Mach3 screenshot [Source: Newfangled Solutions]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb095fc7467a.jpg)

You might be wondering what kind of software drives this system. It turns out to be Mach3, a popular low-cost software tool that “turns a typical computer into a CNC machine controller.” You can download it and try it at no charge, and then later pay the current price of US$175 to legally use the software.

There’s a final chapter that goes over some optional additions to the system, including adding limit switches and an emergency stop button, both of which I would strongly recommend. You do not want your hair, gloves or clothing caught in a CNC machine, no matter how small it might be.

Workshop Tools

Why build this? I believe the addition of an additional making machine to one’s workshop is a powerful step. I’ve always thought that while 3D printing is a very strong making process, it can be complemented by other making technologies to enable more flexibility.

Yes, you can 3D print anything, but you can’t necessarily do it efficiently or cheaply. There are plenty of projects that don’t require a 3D printer per se, but instead could simply use older making processes like CNC milling.

With this book, some parts and some effort, you can have your own CNC machine.

Via Amazon

This week’s selection is “3D Printing Projects” by Dorling Kindersley, a.k.a. “DK”.