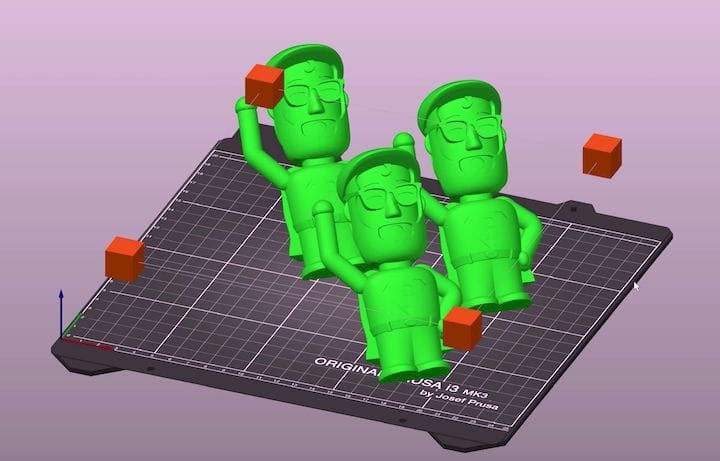

![The plating view from the new PrusaSlicer [Source: Prusa Research]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb096a8eac1c.jpg)

Prusa Research introduced PrusaSlicer to replace their previous management software.

Previous to the announcement, Prusa Research’s main software tool was Slic3r Prusa Edition, sometimes referred to as “Slic3r PE”. This was a fork of the open source Slic3r project that Prusa Research has been incrementally developing for some years.

Why do this switch? There seem to be several reasons.

First, the additions performed by Prusa Research to the tool are significant. Prusa Research has no fewer than seven people assigned full-time to work on this software, and could even add more in the future. Their efforts have added so much to the original Slic3r project that it is really quite a different system.

Secondly, the name of the product is quite confusing. People like to shorten lengthy names for ease of speaking, and in this case “Slic3r PE” was often called “Slic3r”. But wait, what do you call the original Slic3r? The two were being confused.

Thirdly, the name “Slic3r” has an ambiguous pronunciation. Some say it as “slicer”, while others use the absurd “slick-three-arrrr”. I welcome the step away from unpronounceable names, and think “PrusaSlicer” is a terrific product name.

Finally, the system now serves as the single receptacle for all slicing functions required by the company. For example, it now includes slicing capabilities for their new SLA 3D printer, the SL1, in addition to the traditional plastic extrusion methods.

But it’s not just about product names, as the product itself has been dramatically improved with a number of new features.

Prusa Research has done quite a bit of work on the user interface, and specifically has introduced three modes for operation:

-

Simple: A mode for new users that makes invisible all aspects except for the absolute minimum required to begin 3D printing.

-

Advanced: A mode where many practical settings are shown for more advanced users. This is where the majority of experienced users will operate.

-

Expert: A special mode that’s used mostly for those attempting to develop settings for brand new machines.

Even better, all settings are color coded for easy identification of how much trouble you could get into by modifying them:

-

Green: Safe to be tinkered with by a beginner

-

Yellow: Advanced user may want to modify these parameters

-

Red: Expert settings, most of which should only be touched if you’re making a profile for a new printer

They’ve also remade the toolbars to include more easy-to-understand iconography. It seems that the company recognizes their client base includes many people who are new to 3D printing and these changes are certainly directed at them.

There is a new ability to perform changes to the 3D model before printing begins through a new “gizmo”, as they call it. It’s basically a set of manipulation knobs that appear around the 3D model. You can then resize, move, scale and perform other operations in a far easier manner than using a dialog box as in previous versions.

Support structure generation is obviously still provided, but there are now some interesting ways to tweak the generated supports. Usually when a slicing system creates supports, there are areas where it really should not have made them, as well as areas that require supports where they were not generated. The new PrusaSlicer includes “blockers” and “enforcers” that do exactly that. In other words, you can easily tweak the support generation to arrive at the perfect arrangement.

The company has also discontinued their Prusa Control software tool, as its functionality is now being incorporated into PrusaSlicer. Thus, features such as their layer color change solution, “Color Print”, is still available for use.

One new feature I quite appreciate is the automatic calculation of print job estimated time and material use, which was not always visible on prior versions.

There are a number of other new features that will be valuable to 3D printer operators.

I’m quite interested to explore the new version, and I am sure that the very numerous Prusa users worldwide will also be upgrading to PrusaSlicer soon.

Via Prusa Research

MiniFactory’s new software produces a very useful report for each 3D print that may be important for clients. We had a close look at one.