![What’s new? [Image: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/Grimm01a_img_5eb096efc4ac0.jpg)

Industry expert Todd Grimm set the stage for RAPID + TCT 2019 with a speedy rundown of what’s new in 3D printing.

The session, a mainstay kickoff, has proven popular as the fast-talking Grimm does actually run through the presentation. He has to: this industry is fast moving, so fast talking is the only way to hope to capture a snapshot.

RAPID + TCT, as ever, was home to a good number of introductions. For those without the media inbox influx of press releases pointing to every booth’s attractions, Grimm’s discussion during the opening keynote is a remarkably helpful guide to where to go if you want to see what’s new.

We’ll be digging into the meat of many of these soon, as we spoke to many of the companies listed here; as we begin our own RAPID recap, this snapshot of what’s new is a helpful guide for us too to kick off coverage.

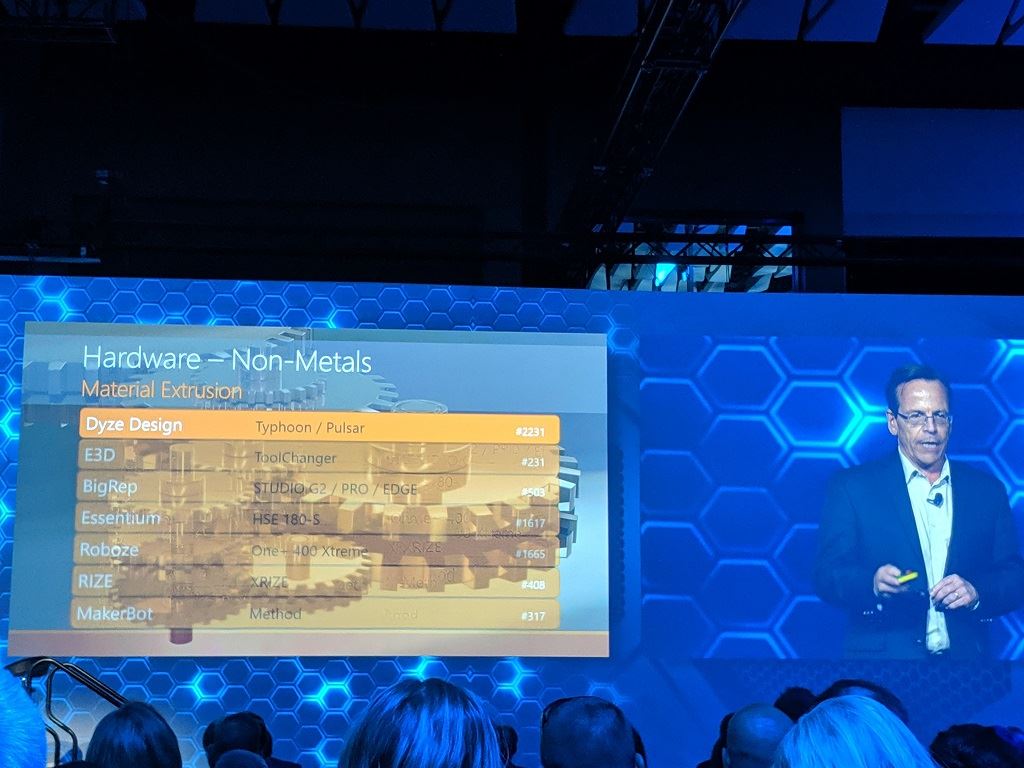

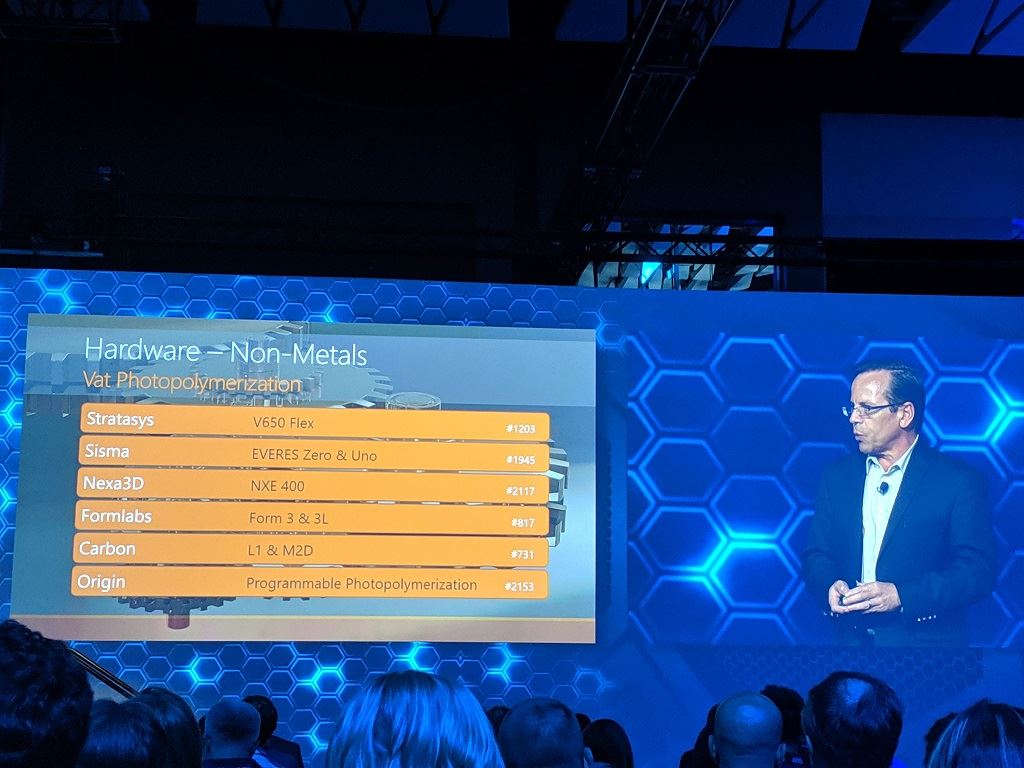

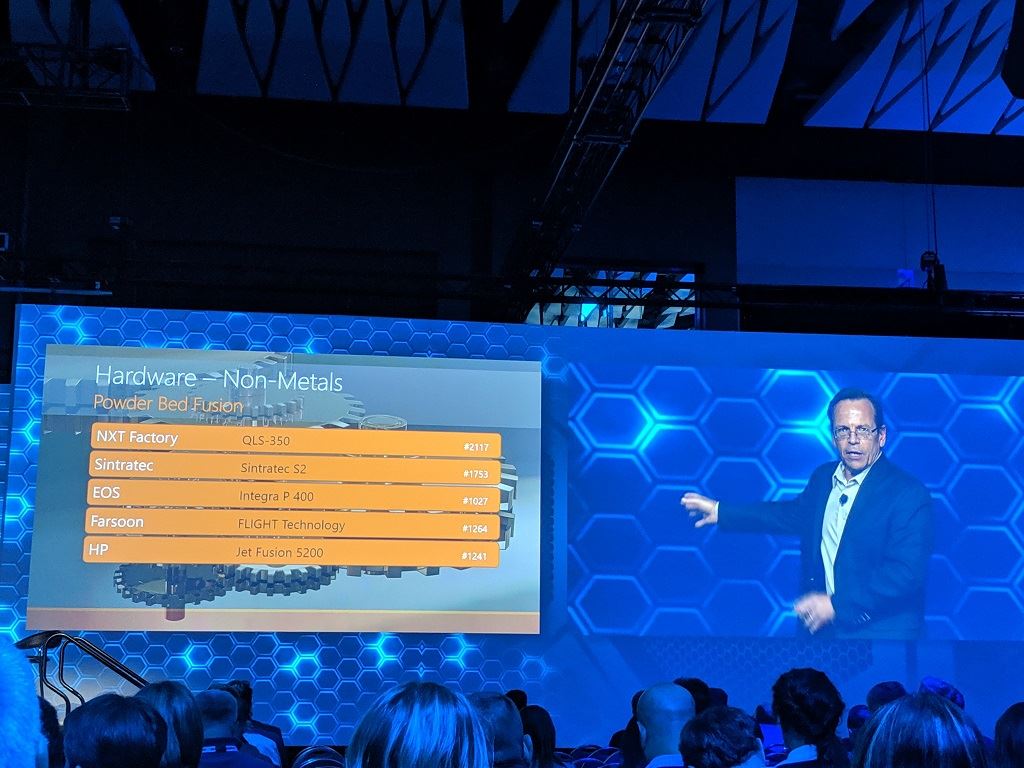

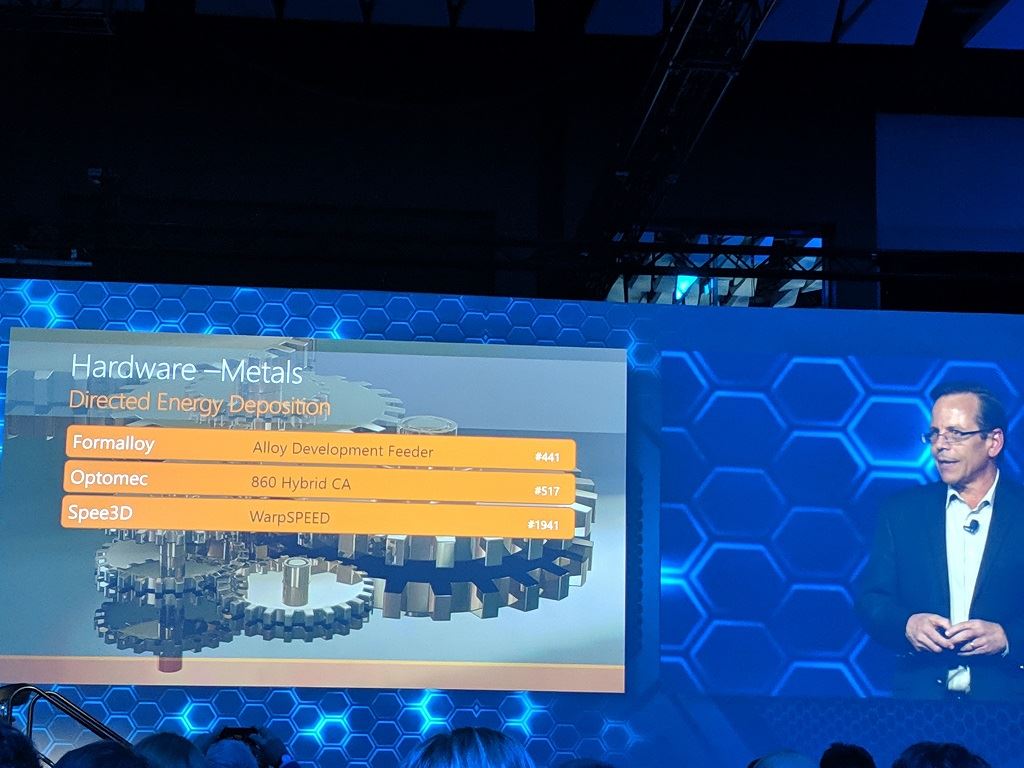

Introductions are segmented into 3D printing hardware, 3D printing software, and 3D scanning, with specific product releases named by company. Helpful for event attendees, Grimm also listed each company’s booth number on the exhibit floor.

Hardware

The look ahead began with hardware: new 3D printers and accessories.

Non-Metals

Material Extrusion

-

Dyze Design — Typhoon / Pulsar

-

E3D — ToolChanger

-

BigRep — STUDIO G2 / PRO / EDGE

-

Essentium — HSE 180-S

-

Roboze — One – 400 Xtreme

-

RIZE — XRIZE

-

MakerBot — Method

Vat Polymerization

-

Stratasys — V650 Flex

-

Sisma — EVERES Zero & Uno

-

Nexa3D — NXE 400

-

Formlabs — Form 3 & 3L

-

Carbon — L1 & M2D

Powder Bed Fusion

-

NXT Factory — QLS-350

-

Sintratec — Sintratec S2

-

EOS — Integra P 400

-

Farsoon — FLIGHT Technology

-

HP — Jet Fusion 5200

Metals

Binder Jetting

-

ExOne — X1 25PRO

Directed Energy Deposition

-

Formalloy — Alloy Development Feeder

-

Optomec — 860 Hybrid CA

-

SPEE3D — WarpSPEE3D

Powder Bed Fusion

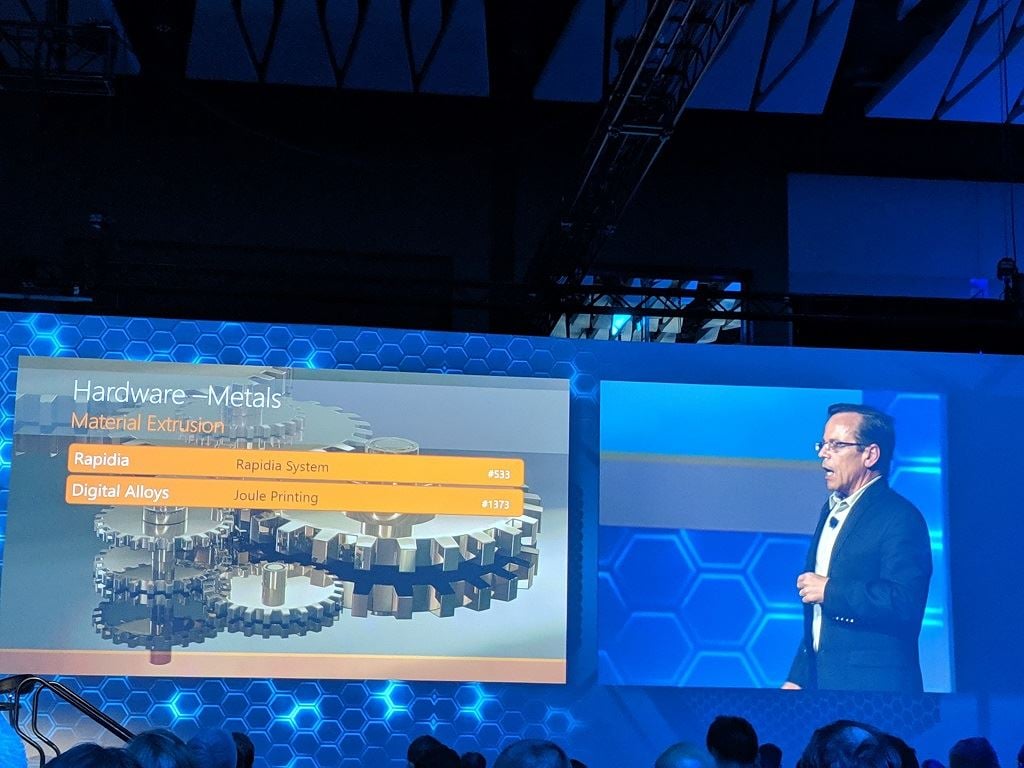

Material Extrusion

-

Rapidia — Rapidia System

-

Digital Alloys** — Joule Printing

-

**Please note that per Digital Alloys, Joule Printing is not actually an extrusion-based process; they clarify: The process is not extrusion based, as we are feeding a solid wire through the print tip. It only becomes molten once it touches the part and is heated by resistance heating (aka Joule Heating) by electricity flowing through it. There’s a more detailed explanation, with some video, here.

-

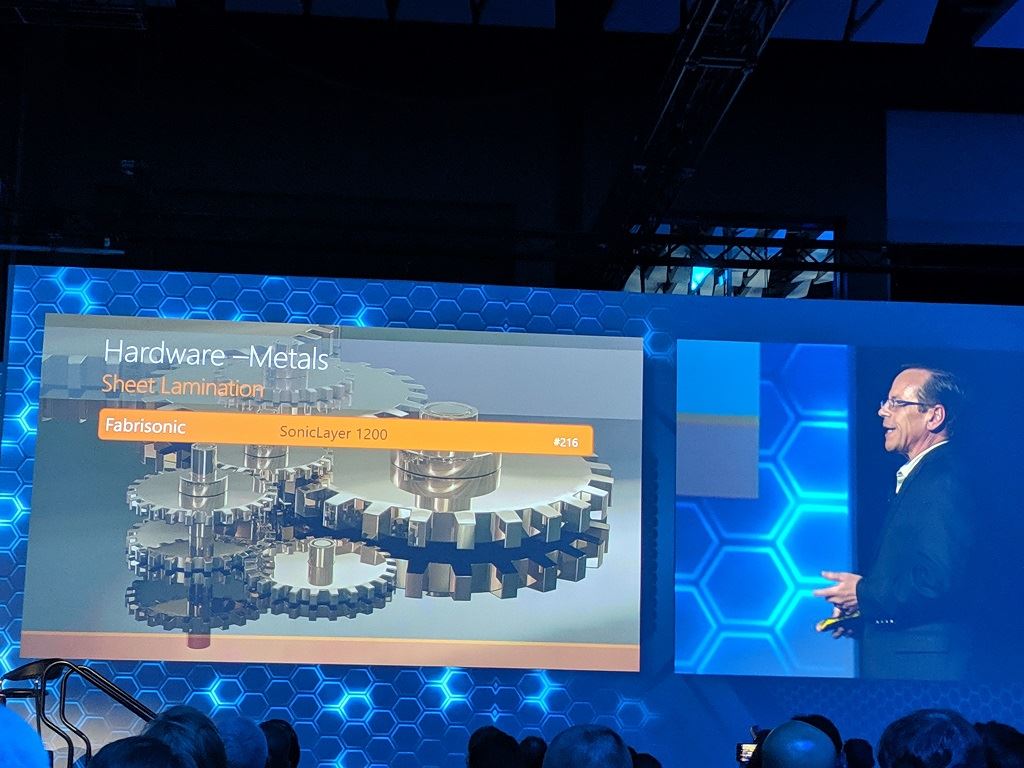

Sheet Laminator

-

Fabrisonic — SonicLayer 1200

Software

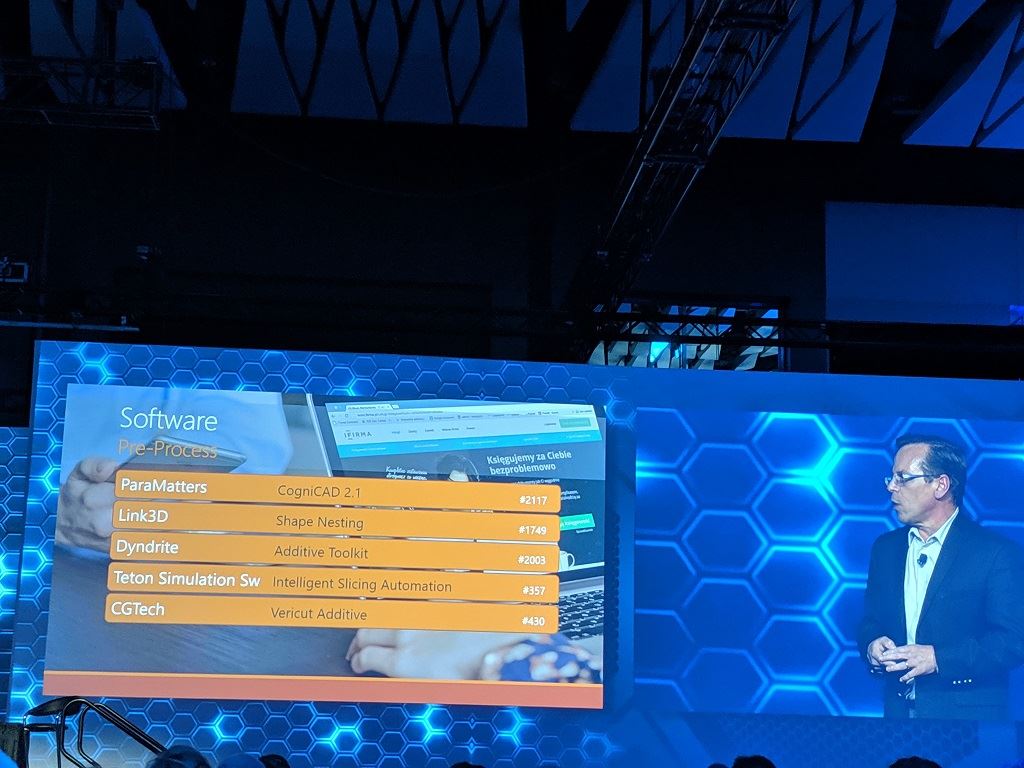

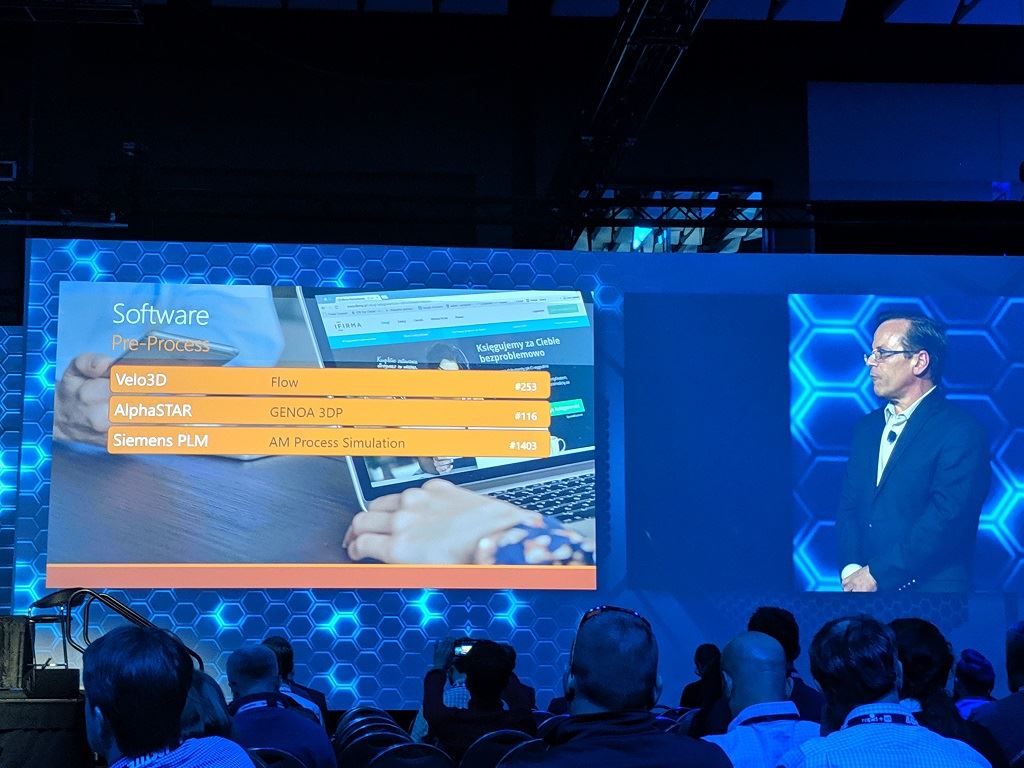

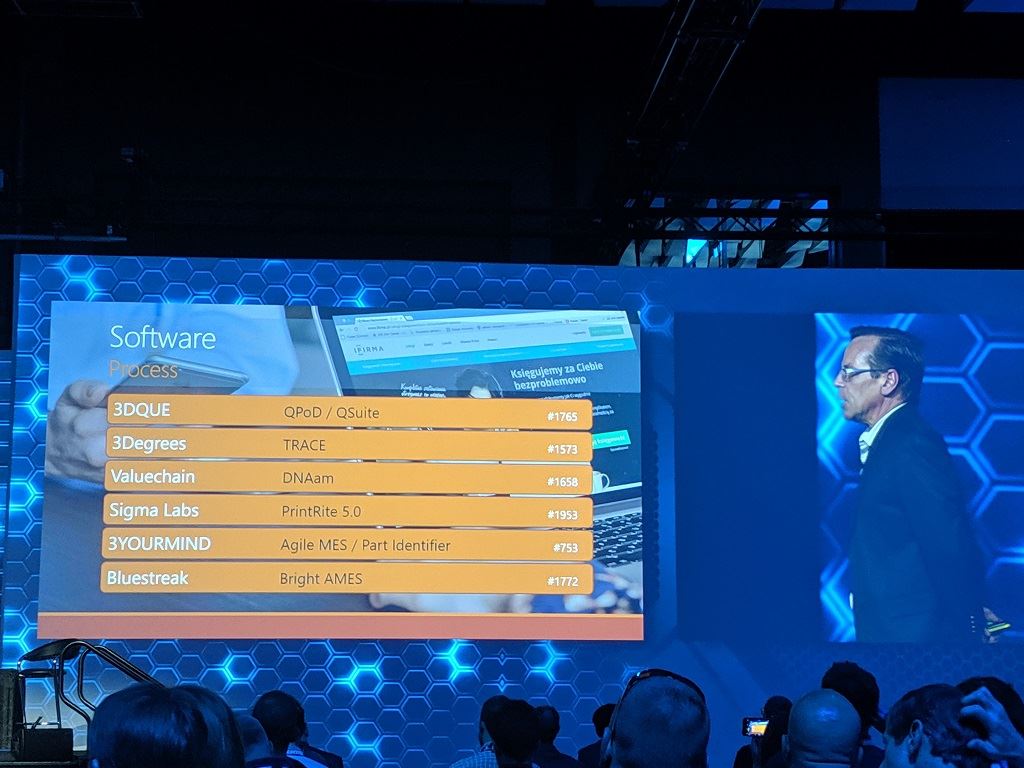

Software for 3D printing is broken up into a few categories, based on where in the end-to-end additive manufacturing process each introduction comes into play.

Pre-Process

-

ParaMatters — CogniCAD 2.1

-

Link3D — Shape Nesting

-

Dyndrite — Additive Toolkit

-

Teton Simulation Software — Intelligent Slicing Automation

-

CGTech — Vericut Additive

-

Velo3D — Flow

-

AlphaSTAR — GENOA 3DP

-

Siemens PLM — AM Process Simulation

Process

-

3DQUE — QPoD / QSuite

-

3Degrees — TRACE

-

Valuechain — DNAam

-

Sigma Labs — PrintRite 5.0

-

3YOURMIND — Agile MES / Part Identifier

-

Bluestreak — Bright AMES

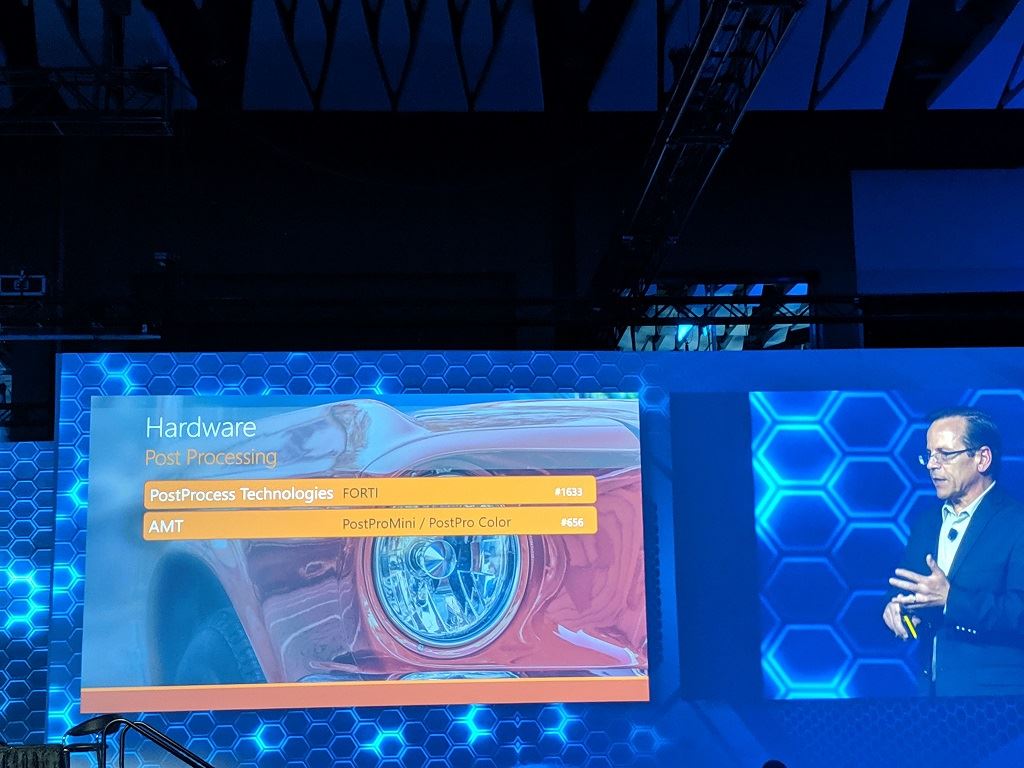

Post-Processing

-

PostProcess Technologies — FORTI

-

AMT — PostProMini / PostPro Color

3D Scanning

![New 3D scanning introductions [Image: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/Grimm14a_img_5eb096f53198e.jpg)

With time running short, Grimm also pointed to advances and new introductions in 3D scanning, which is of course tied into the 3D workflow.

We’ve linked to some of these introductions we’ve covered, and interviewed a good many of these companies during RAPID + TCT — so there’s plenty more to come on these and other technologies soon!

The fate of major 3D printing conferences in 2020 is unclear with the ongoing virus outbreak. We have thoughts on what it could mean.