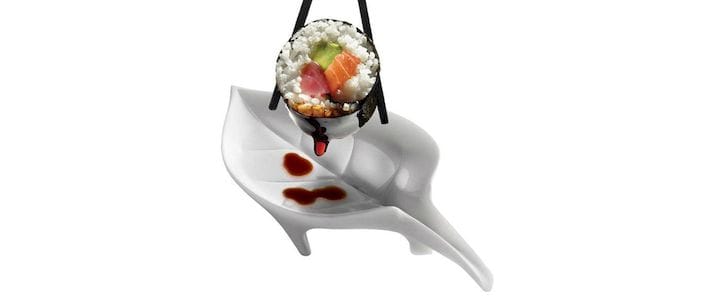

![Is that 3D print food-safe? [Source: Formlabs]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09aa84182f.jpg)

I’ve just reviewed what seems to be the most comprehensive resource I’ve yet seen regarding 3D printing food safety.

The long piece was published by Formlabs, a well-known maker of SLA-style desktop 3D printers (the Form 1 and 2), and soon an SLS machine (the Fuse) as well.

They seem to have properly researched appropriate governmental recommendations and applied them to the 3D printing scene. They start with official declarations and definitions of food safety as obtained from regulatory material.

The report covers not only the food safety issues inherent in SLA and SLS 3D printing technologies, but even goes as far as to describe the same issues in plastic extrusion 3D printing methods, which have never been used by Formlabs, making this a truly industry-wide resource. Good on Formlabs!

Right off the top, Formlabs says:

”PLEASE NOTE: No Formlabs resins are food safe unless users take additional steps.”

3D print materials can notoriously be toxic. Most resins for SLA 3D printing are not food-safe and are even toxic, and solid 3D print filaments can often be corrupted with additives and colorants, some of which include lead, a known toxic material. And that’s before any 3D printing even begins.

Food safety is routinely ignored by many using desktop 3D printers. In fact, I have one 3D printing acquaintance who persists in 3D printing cookie cutters, regardless of my warnings. You Know Who You Are!

Sure, the risks are small, as the problems develop from longer-term exposure to toxic materials. A brief touch during a baking session provides only a very limited opportunity for toxic materials present in the 3D printed material to other foods or humans. However, if you do this repeatedly, then you may be generating a long-term risk similar to holding a liquid in a 3D printed cup for an extended duration.

The Formlabs report lists workable solutions for almost every situation, and many of them involve coating the 3D printed object in a food-safe covering. To their credit, they also disclaim that as a final solution, because it is always possible that a coating may wear off, exposing the toxic material underneath.

Another solution they suggest several times is the molding approach, where a 3D print is simply used as a model for a mold made from true food-safe material. This has been most frequently done with chocolate, and it works very well.

All aspects of food safety are covered in the Formlabs report, including a warning to check whether the machine itself is food-safe. That means that the entire path through the machine followed by the material (which we hope is food-safe itself) is lain with food safe materials. For example, some 3D printer plastic extrusion machines employ brass nozzles containing lead. That’s definitely not good.

While the report is comprehensive and in all ways excellent, there is one question I still ponder: how much time did Formlabs’ lawyers take to review and approve this piece?

Via Formlabs

The fate of major 3D printing conferences in 2020 is unclear with the ongoing virus outbreak. We have thoughts on what it could mean.