![A neatly sliced 3D model ready for printing in 3DWOX Desktop [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09bd2ca3ef.jpg)

I’ve been exploring the latest version of 3DWOX Desktop and bumped into some interesting features.

The software is, of course, bundled with 3DWOX 3D printers and exclusively for use with that brand, unlike open source alternatives or third party slicers like Simplify3D. Nevertheless, there are some unusual features buried in the tool we’d like to talk about.

3DWOX Desktop does perform all the usual expected tasks taken on by 3D print slicers, including positioning, orientation of objects, setting print parameters like infill percentage, perimeter count, layer thickness, etc. It also will generate support structures and provide remote access, control and monitoring of prints through a network.

But 3DWOX Desktop seems to include a couple of quite powerful features usually not seen in slicing systems.

The Analysis functions are quite useful. There’s two modes, one for analyzing wall thickness and the other for overhang angle.

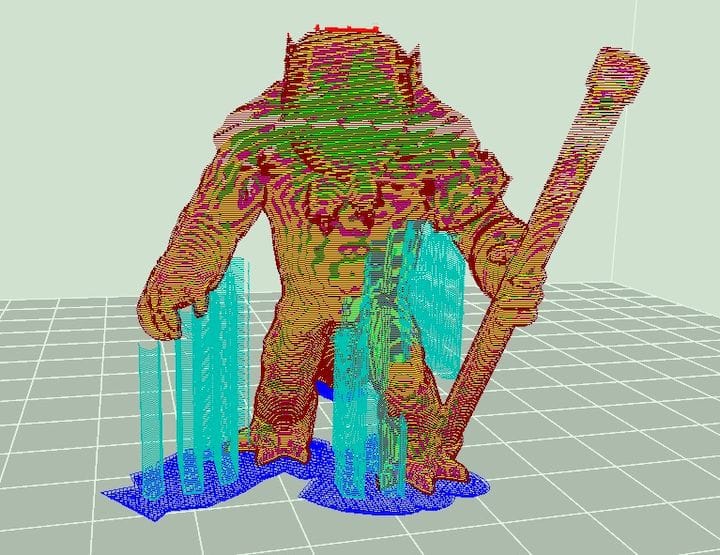

![Analyzing the thickness of a 3D model in real time using 3DWOX Desktop [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09bd33b79c.jpg)

Here we see the wall thickness analysis tool in action. As you might expect, it highlights the areas below a given thickness, so you can immediately identify problematic areas in your print. But the absolutely brilliant thing here is that the thickness factor is on a real-time slider! You can slide the bar left or right to see where the thin components appear.

![Analyzing the effect of different overhang angles on a 3D model in real time using 3DWOX Desktop [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09bd389584.jpg)

Similarly, the overhang angle provides a real-time view of varying angles. This is incredibly useful when deciding whether or not to apply support structures to a given 3D model. By shifting the slider you can very quickly determine the “right” overhang angle for a 3D model that when used as the support angle generator will produce the optimum amount of support — not too much and not too little.

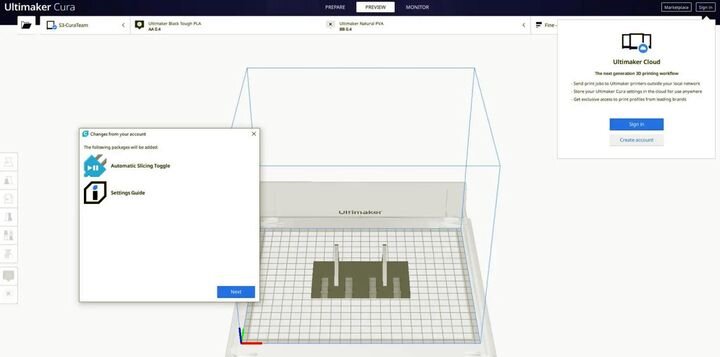

If that isn’t enough for developing correct support structures, they also include an unusual “support editor”.

![Generating and editing support structures using 3DWOX Desktop [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09bd3cb532.jpg)

Here you can see a screen capture of the support editor in action. The support structures appear, and can be removed or added as required. But there’s an unusual “plane” that can be shifted up or down. On this plane appears a “shadow” of the object as if illuminated from above. Thus you can very clearly see what is going on in any given support scenario.

Another very interesting feature is the automated orientation analysis. This takes as input a model from the build plate and attempts to determine the best orientation for 3D printing.

![Determining the best orientation of a 3D model using 3DWOX Desktop [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09bd42130e.jpg)

Here we see an example of this analysis on a small part, where it correctly selects the best orientation for 3D printing. I’m not quite sure how they do this analysis, as one might have conflicting objectives in mind. The masterminds behind this software must have made some assumptions about what people may want most, as it is usually a compromise between print speed, print quality and support structure requirements.

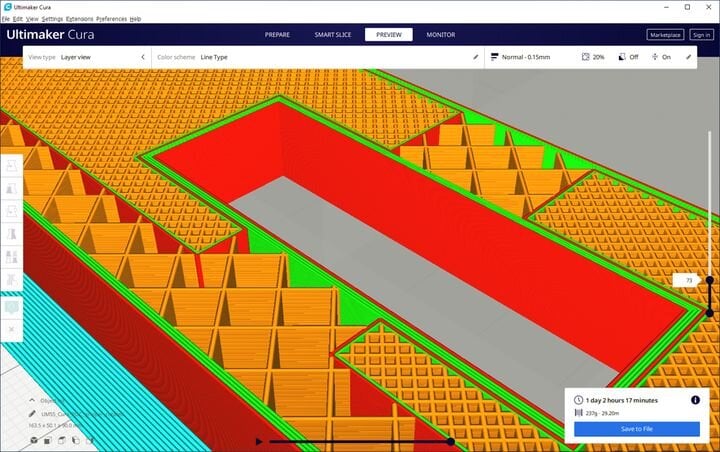

![Advanced slicing options in 3DWOX Desktop [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09bd488e6b.jpg)

3DWOX Desktop also includes a number of interesting options not always present in 3D print slicers. Here we see things like “vase mode”, or as they say, “spiralize”; printing only the sides, not the top or bottom; combining ambiguous 3D models by either performing a boolean “union” or “intersection” of overlapping parts; automatically closing holes — or not; and what they say is a “fix horrible” option to perform drastic repairs on a pathological 3D model.

Finally, I’m told the latest version of 3DWOX Desktop includes a feature that allows the print to pause for a filament swap. This would be useful if you wanted to change colors mid-print, for example. However, in spite of hearing of such a feature, I cannot figure out how it’s done. If you know, please tell me!

The 3DWOX Desktop software is really only for use with Sindoh’s 3DWOX equipment, but these advanced features are certainly desirable in any 3D print slicing system. I’m hoping they appear in some of the other tools in future releases.

Via Sindoh

MiniFactory’s new software produces a very useful report for each 3D print that may be important for clients. We had a close look at one.