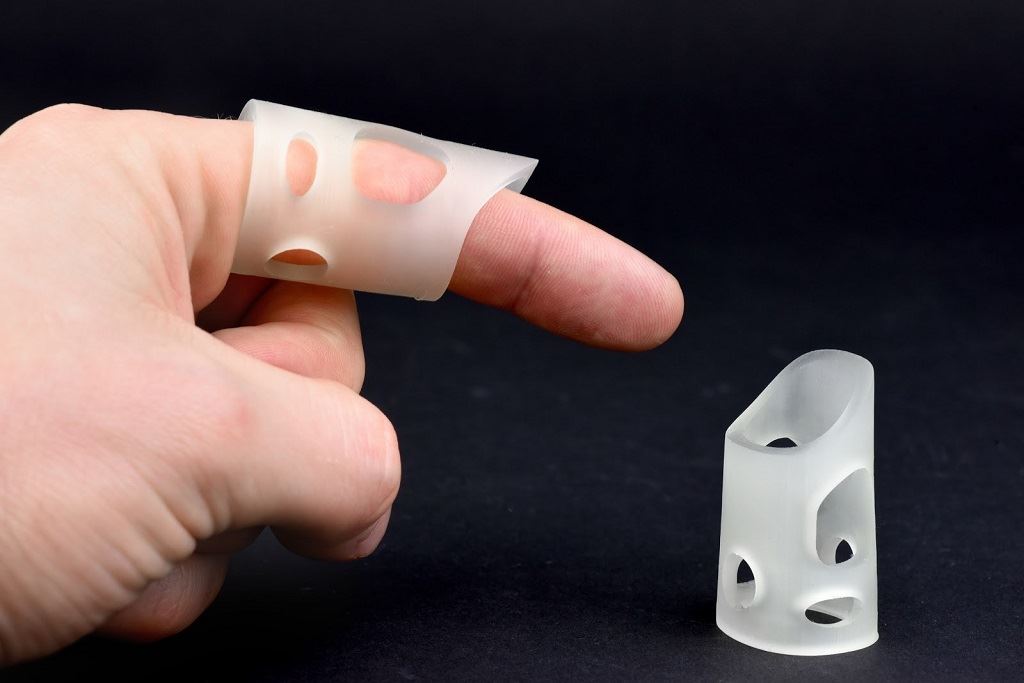

![Finger splint printed on Origin with Henkel silicone [Image: Origin / Design: ibataeva ]](https://fabbaloo.com/wp-content/uploads/2020/05/henkelorigin1_img_5eb09bed03d17.jpg)

Open material platforms represent an increasingly winning approach in 3D printing.

“Open” tends to indicate “not proprietary” more than a “use whatever materials” free-for-all, and it’s a popular collaborative strategy these days.

Locking in users to proprietary materials made in-house ensures that the parameters are understood and that the material will work as intended and designed. It also often leads to significant markups, as there’s only one source for the materials. We’ve seen it in 2D printing, and that mentality — affordable printer, expensive ink/consumables — moved into 3D printing too.

But the proprietary lines aren’t always the best option, they’re just the only option. Users want choice. Some builds need to be flexible, while others require superior mechanical strength. Some are quick mockups, others functional parts. So an increasing number of industrial systems are forming partnerships for open platforms.

Collaborating with chemical companies creates new choice in 3D printing.

The full additive manufacturing ecosystem is comprised of many moving parts: design, preparation, the actual 3D printing, post-processing. Tying in expertise from more than one area is leading to better results: if X knows materials and Y knows materials, the XY collaboration can bring them together for a stronger pairing (and stronger still by bringing in Z’s software expertise).

These partnerships are churning out, and they’re good to see. Some of them are even built into the foundations of a company.

Origin, which had been in stealth for some time, fully emerged recently with solid funding and an interesting approach to 3D printing.

Their P3 process (programmable photopolymerization) is a resin-based 3D printing technology that is being built with platform thinking. The solution “integrates modular hardware, extensible software, and new materials,” the company says.

Those new materials are being developed in Origin’s Open Material Network, which currently includes chemical partners BASF and, more recently announced, Henkel.

Henkel, which has been dipping its toes in the 3D printing waters with increasing visibility, is among the ranks of well-known materials companies investing in the additive arena.

For Origin, a key part of working with experts in materials is that all-important offering: choice.

“We are eager to give customers even more material options in a diverse range of portfolio materials that can take advantage of our (P3) process such as silicones, epoxies, and polyurethanes. We believe our open network approach with Henkel and other strategic partners will fundamentally reshape manufacturing and global supply chains and we look forward to unveiling world-class and industry-defining projects in development with Henkel in the coming months,” said Chris Prucha, Founder and CEO of Origin.

Materials to emerge from this partnership are slated for “focus on additive mass production for the medical, automotive, and other industrial sectors.” Several medical device-appropriate biocompatible materials have already been validated, the companies note.

The partnership announcement adds:

“Notably, Henkel’s parent silicone resins have tested to Henkel’s protocols based upon ISO-10993 biocompatibility standards.”

That tie-in, with ISO certifications, means something else for the open materials thinking: trust. Especially moving into markets that require great trust and reliability, like medical, 3D printing has a lot to prove. Working with already-trusted names with established and certified operations goes a long way to validating new introductions.

These announcements are coming in more regularly, and we should only expect that pace to accelerate. As big names in chemicals and materials continue to invest into additive manufacturing, work with established hardware manufacturers will continue to bring new mechanical properties to more applications.

Via Origin

FELIXprinters has released a new bioprinter, the FELIX BIOprinter, which is quite a change for the long-time 3D printer manufacturer.