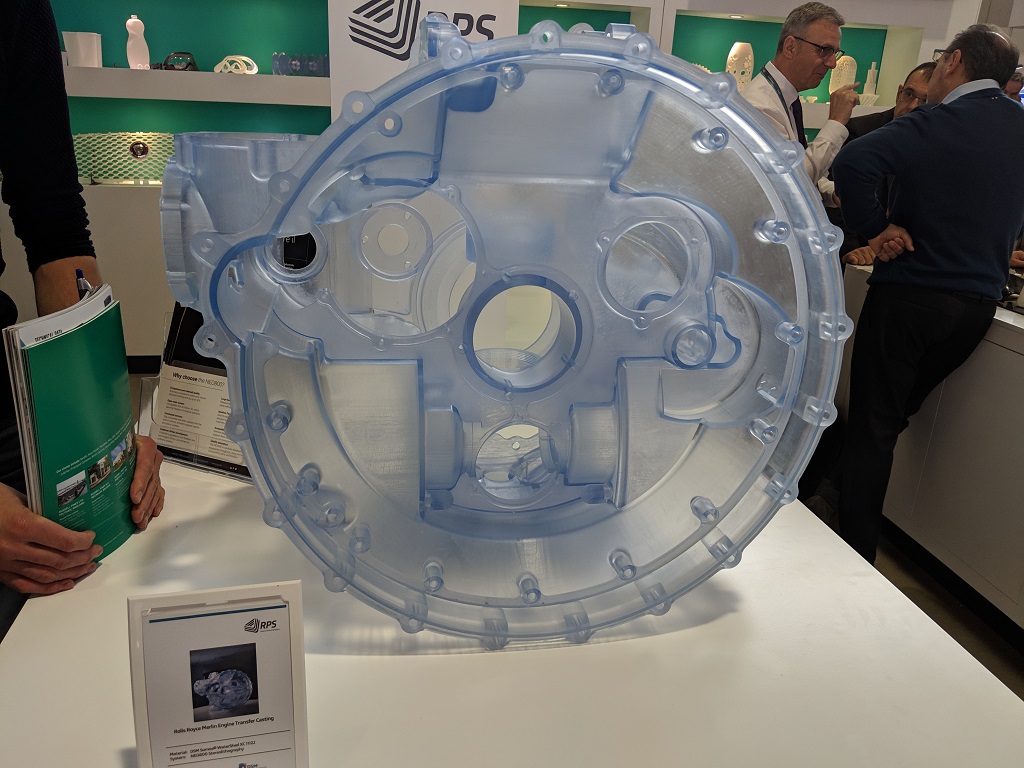

![The NEO800 and some of its detailed prints [Image: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/IMG_20181114_142431_img_5eb09c086e619.jpg)

The large-format industrial NEO800 SLA system is built from experience.

No one knows 3D printing like the people who use it all the time. So engineers at UK-based RPS, having built up years of experience in fixing and working with 3D printers, decided to build their own. The industrial system that resulted, the NEO800, is an open machine capable of some excellent part quality.

Also built from the engineers’ experience is the Titanium software powering the system.

Designed to work with Windows 10, the user-friendly interface requires “a couple pushes of a button to use,” Production and Development Manager Simon Tyler explained as he walked me through it. The system is equipped with a built-in camera to monitor builds, which can be adjusted during the print without a pause to see changes in the next layer. Mid-build, recoating build styles and part build styles can be changed, or parts and supports can be deleted. It’s all about ensuring the print goes off the way it’s intended to; “it caters for everybody, is the hope,” Tyler added.

“We have a good group with a lot of experience with SLA,” Tyler said of the team behind the NEO800 and Titanium software. “I’ve spent my entire working life, since 2001, with SLA. You have to listen to people and what they want. It creates a stronger bond, and repeat customers.”

The software is updated about every four months, and “every update has something someone has asked for, which is something I’m very keen on,” Tyler noted. The next update following our conversation was built with not only the usual software updates, but also new features based on feedback received, including the addition of build logs.

Tying in to that feedback loop is regular contact with the system’s users. Support is key to the RPS approach (so key “support” is the S in the company’s name). Any problems with print quality can be tracked down easily. Tyler demonstrated that it does indeed take just a few pushes of a button to create and email a seven-day build log to RPS service to problem shoot and solve issues.

Back to the machine itself, it’s a beast of a system. There’s always something pleasant about seeing a large industrial system that creates dainty prints, and that’s just what I got with the NEO800. Delicate vases and intricate car grilles were available for inspection of detailing.

The NEO800 has “a very simple design, but a very designed design,” as Tyler put it. The structure stands quite tall, around 7’ maybe, all the better to accommodate a large 800 x 800 x 600 mm build platform.

“It was made for repeatability,” Tyler said. “We used our history as service engineers to build this system.”

When it comes to materials, the NEO800 is very open.

“It’s an open machine; nothing is locked down. It’s completely open from a materials point of view,” Tyler noted.

RPS does have a partnership with DSM Somos, and the system is certified to work with DSM’s PerForm, EvoLVe 128, Watershed, and Taurus materials. Any 355nm SLA resins are compatible with the machine, though.

Accessories for the NEO800 include an offload trolley and the UV800 system that comes pre-programmed with post-curing cycles and keeps the user friendliness up with a touchscreen interface.

The parts I examined during our chat had all been cured, of course, but Tyler noted a point of interest: they’d had no post-processing beyond that.

RPS has kept up with its general 3D printing expertise, as well. The company is a reseller for HP’s Multi Jet Fusion 3D printers; offers materials for MJF, SLA, and (in partnership with ALM) SLS processes; resells new and used 3D printing equipment; and has a partnership with Materialise to offer Magics software. Service and support for industrial SLS/SLA/MJF systems is available, including laser refurbs and system upgrades as well as maintenance and technical advice.

Sometimes it’s nice to talk to those who simply do it all — and nicer still when they build that know-how into operations and offerings.

Via RPS

Formlabs just issued three new videos for beginners to 3D printing, and the result was quite surprising.