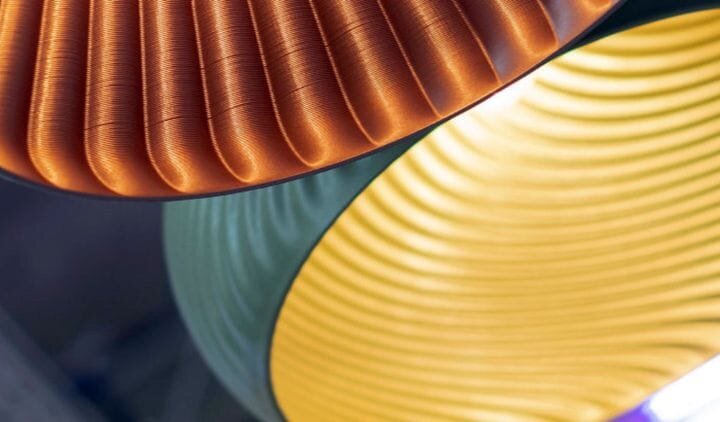

![3D printed luminaires [Source: Signify]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08cb5a1cfc.jpg)

Signify (formerly Philips Lighting) announced a plan to mass customize lighting products using 3D printing technology.

The Netherlands-based company has long been a leader in lighting, both commercial and residential, but now they seem to be taking a huge step into a new world of mass customization.

The project is to allow customers to specify characteristics of “luminaries”, or “light shades and fittings”. These are snap-fit units that can be easily attached by the customer to their lighting systems to provide a personalized lighting experience.

Signify Increases Sustainability

One of the goals of the project is to increase sustainability of lighting products. Signify says that the new method of producing luminaires has a 47% smaller carbon footprint than their previous process – and at the same time the products are customizable by the customer.

Signify offers a number of 3D printed products, and the customer can specify the model, color, texture and other characteristics. Signify then 3D prints an end-use instance of the product according to the customer parameters and ships it out.

It seems that many commercial customers are making heavy use of this product type. Signify reports that UK-based Marks and Spencer are to install “thousands” of 3D printed luminaires in their stores. Signify has already established relationships with other major corporations such as Praxis, Total, Albert Heijn and SAS.

Signify 3D Printing Sustainability

There’s more to the sustainability than just the production of the luminaires. The products are actually less weight than previous versions, and this should save costs and carbon consumed for shipping.

In addition, the luminaires are designed to snap-ft onto their fixtures, meaning the customer does not require the use of glue, another sustainability advantage.

Signify 3D Printing Facilities

Here’s the really interesting part. Signify says:

“Signify already has a 3D printing facility at Maarheeze in the Netherlands. It aims to have up to 500 3D printers of different sizes with the ability to create luminaires up to 60 cm height and width.

In January 2020, new Signify 3D printing facilities will be operational in Burlington, Massachusetts, US, serving both professional and consumer markets. Additional facilities in Noida, India and Jakarta, Indonesia will follow quickly after. LED lights will be integrated into the luminaires at all these sites.”

Signify’s 500 3D Printers?

Five hundred 3D printers is no small matter, and would surely represent one of the largest 3D printing organizations in the world for any type of product, yet all of these will be dedicated to producing lighting products.

It’s not clear what type of 3D printers will be installed in Signify’s locations, but it’s likely to be from several different manufacturers if they hope to achieve “different sizes”. I suspect they will not choose expensive industrial units as the cost would be outrageous, when they could use arrays of less expensive devices to produce similar output.

Regardless, I’m certain multiple 3D printer vendors are now knocking on Signify’s door with proposals.

Via Signify