![Robotically assembled structures? [Source: University of Stuttgart]](https://fabbaloo.com/wp-content/uploads/2020/05/robotic-assembly_img_5eb08c51d30cb.jpg)

I’m looking at a paper from the University of Stuttgart describing an unusual “timber assembly system”.

The idea here is to employ a swarm of robots to assembly an entire structure out of timber lengths, all without any human intervention.

Robotic Assembly

![Robotic assembly hardware [Source: University of Stuttgart]](https://fabbaloo.com/wp-content/uploads/2020/05/robotic-assembly-robot_img_5eb08c5221ab5.jpg)

The robots used in this experiment are surprisingly simple: they have two clamping systems, one to hold the robot fast on a timer, and the other to grasp timer pieces. The robot itself can rotate.

That doesn’t sound particularly complex, but when used in concert with many identical robots, surprisingly complex sequences can be engaged to effect movement and placement of timbers, particularly with many robots on site.

A timber could be picked up by robot A, then with a rotation it could pass it to robot B, which then passes it to robot C for final placement. Such sequences can be arbitrarily complex, and likely extraordinary complex for larger structures.

The robots are also capable of fastening the timbers together using screws.

Robotic Assembly Software

What’s really fascinating is how the robots can move themselves around the build site into position, suggesting complex software must be used to develop the “tool path” for this equipment.

Towards the end of their video you can see a set of prototype robots quickly build a tall structure, so it’s clear this concept is not just for 2D arrangements:

Assembly As 3D Printing?

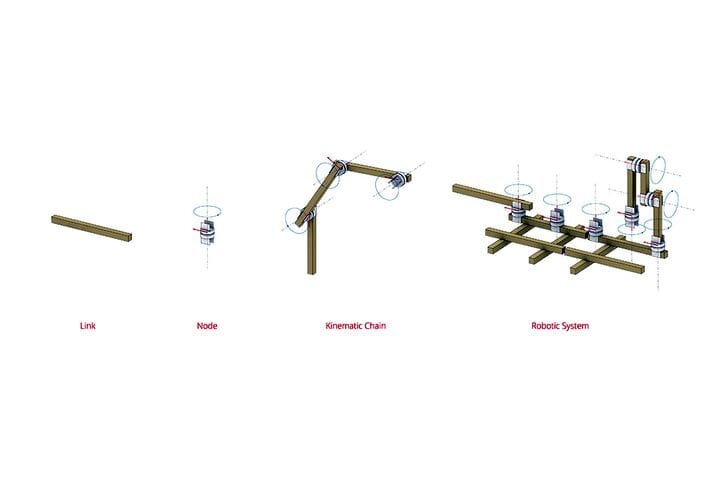

![Robotic assembly basic methods [Source: University of Stuttgart]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08c526ba79.jpg)

This is all quite interesting, but is it 3D printing?

I argue yes.

What are 3D printers? How are they defined? There really isn’t a formal definition, but I would say it is a machine using a primarily additive process to produce 3D objects. And that is precisely what is happening in the Stuttgart experiment: material (timber sections) are being deposited to form a 3D structure.

I suppose this technique would be called “Timber 3D Printing”, but really I think this approach to making could be a very important concept for the future.

Imagine a set of building components more complex than the uniform set of timbers used by the Stuttgart experiment. These might have standard mounting points where they can be grabbed by robots. Such a complex system could overcome some of the limitations of the “uniform” system from Stuttgart.

It might then be possible to truly assemble a proper and fully functional structure, such as a house. Even overhangs could be handled by building temporary support structures “scaffolds”, that could be removed by the robots after printing the main structure.

This is getting close to the type of technology required to actually 3D print a home in 24 hours, something many construction 3D printer companies boasted of incorrectly.

I encourage further research on this concept and especially if it could be extended to be used for multiple material shapes.