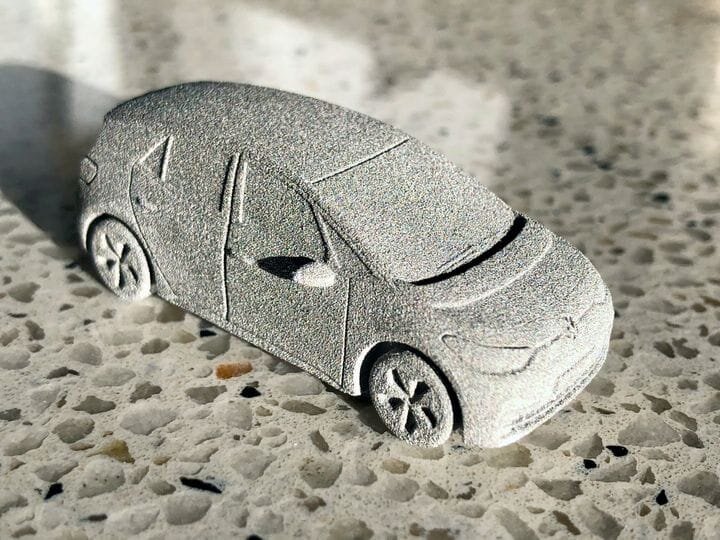

![A 3D printed version of Volkswagen’s new ID.3 electric vehicle, made by GKN [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/hp-volkswagen-1_img_5eb08c55a922b.jpg)

I’m reading a piece from HP discussing their work with Volkswagen, and had a thought about how things are playing out for 3D printing in the automotive industry.

The news from HP is that after introducing their HP Metal Jet technology just over a year ago, they now have several customers making good use of the metal 3D printing process. Apparently the German-based automaker was able to produce over 10,000 end-use metal parts within only a few weeks, with the help of HP and GKN Powder Metallurgy.

That’s very good news and a clear demonstration of how fast advanced metal parts can be produced using 3D printing technology. Note that the 10,000 were not prototypes, but were in fact final parts.

Now, the interesting part. The metal components were produced for Volkswagen’s new EV, the ID.3. This is perhaps the big strategic move for Volkswagen into the new world of electric vehicles, something many automakers must do, and soon.

There’s something happening in the automotive industry, if you haven’t noticed yet: a mass conversion to electric vehicles is now underway. Of course, this will take many years to complete, but the facts of the matter are that we are now past the tipping point and virtually all automakers now realize they have to undertake a conversion. Some automakers have even announced they will no longer produce fossil-fueled vehicles at particular future dates.

Automaker EV Transformation

However, it’s taken a significant push to motivate the automakers, as they had plenty of motivation to maintain their current business model. The problem involves car dealers, who are independent organizations selling the automaker’s products. It turns out that these dealers make the vast majority of their revenue on vehicle maintenance and repairs.

But electric vehicles have significantly far fewer parts and notably fewer mechanical components prone to failure. A properly designed EV requires dramatically less maintenance, to the point where Tesla, the leading EV maker, prefers to provide mobile service over traditional service centers.

If the dealers were to exclusively sell EVs, their revenue would drop off, perhaps to the point where they would begin to close down. Then who would sell the automakers’ cars? That’s the dilemma automakers find themselves in, and why they haven’t moved on EVs until now.

Due to the success of certain EV brands, most notably Tesla, consumers are now strongly buying EVs after discovering the advantages. While the current percentage of vehicle sales is still low, it is set to change dramatically in years to come.

It does take many years to develop a new vehicle, particularly one with an entirely new power source. While Tesla and others are already in the market with accepted products, many automakers now find themselves far behind in the race to EVs.

Automotive Additive Manufacturing Benefits

That’s where I believe 3D printing can provide some help. Automakers are under the gun to develop new EV concepts as fast as they possibly can. Even Volkswagen’s new ID.3 has seemingly been rushed forward, as there are reports of software issues that require resolution.

3D printing can help in two ways. Not surprisingly, one is prototyping. It is entirely possible to literally produce new metal component prototypes overnight using metal 3D printing, of which HP is an option. In an earlier age of automobile development, this could have taken weeks, leading to fantastically long overall development sequences.

The second possibility is production. Normally, metal parts for automobiles would be produced using traditional methods, but perhaps even that would take too long to do. Traditional manufacturing would require significant effort and cost to set up production lines, but there is no requirement for that with 3D printed solutions.

Certainly there is the cost factor: 3D printed components will likely be more expensive than traditionally made components. However, with the opportunity to create entirely new components for new vehicles, engineers are free to experiment with radically new component designs that were not producible using traditional making processes.

3D Print Stock Prediction

These radically new components might provide key advantages to the automaker in their efforts to catch up in the EV race.

If so, there could be a mad rush to acquire production metal 3D printing gear. Watch those stock prices closely!

Via HP Metal