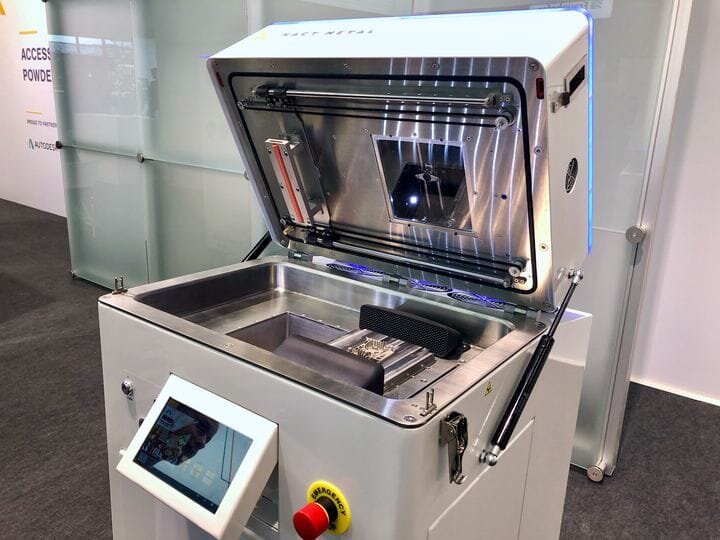

![One of Xact Metal’s metal 3D printers in open mode [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/xact-metal-open-1_img_5eb08c72348a2.jpg)

I spoke with Xact Metal CEO Juan Mario Gomez to find out what’s been happening with their inexpensive metal 3D printing technology.

The company was first seen only a few years ago, when the startup emerged to show a relatively inexpensive metal 3D printer that attracted some attention.

Now, a few years later, the competition is tough in the metal 3D printing market, with new entrants, technologies and geographies involved. Today they offer three different machines, the XM200C, XM200S and XM300C.

It’s hard for any player to keep up, but Xact Metal has been working on some interesting new features in their equipment that should keep them at top of mind. They seem to have two goals in mind: simplifying operations and reducing cost.

New Xact Metal 3D Printer Features

The operational simplification manifests as several new features in their equipment. One is a “fast purge”, which is a method of purging oxygen from the build chamber before 3D printing can commence. The new purge system can evacuate air at a rate 2-3X faster than their previous system, making the machine ready for 3D printing a lot quicker.

Adaptive Charge

Another new feature is something they call “adaptive charge”, which is a way of dynamically managing the recoating process, where each new layer of the 3D print job lays down a fresh layer of powder. This helps avoid situations where a 3D print operator must pause the print and change print parameters in the middle of the night. That will certainly be a welcome feature.

Xact Metal Quality Control

Another feature that’s been appearing on several machines we’ve seen lately and now also on the Xact Metal equipment is an image-based print quality control system. Here’s how it works: after each layer is printed, an onboard camera takes a picture of the new layer’s outcome. These are instantly analyzed to ensure they match what was expected. If not, an email alarm is sent to the operator, who can then choose to stop the print if necessary to save on the expensive metal powder material that would otherwise be wasted on a failed print.

The cost savings change is I think the most interesting new feature from Xact Metal, but I need to explain a bit of background first.

Galvo Laser 3D Printers

Most metal 3D printers use a galvanometric system in which a powerful laser beam hits a tilting mirror. The beam is then directed to areas of the powder bed for sintering. However, there are two challenges with this approach. First, as the beam is angled, the laser spot is no longer round; it’s an ellipse. This can cause strange print quality aberrations on the periphery of the print surface, and sometimes leads manufacturers to mount the mirror very high to minimize this effect.

We explained this effect in our story “Why Are Metal 3D Printers So Tall” last year.

The second problem is that galvanometric systems are relatively expensive. However, they do operate quite rapidly, as a slight twist of the mirror’s angle can instantly sweep the laser to any portion of the print surface.

Xact Metal Dynamic Laser Spot

Meanwhile, Xact Metal does not use a “galvo” mechanism in their equipment; instead the laser is simply fired at a fixed mirror that moves about with a standard (and inexpensive) cartesian motion system. But while it’s less expensive, it’s also a lot slower than a galvo system.

Until now! Xact Metal has devised an intriguing solution to the issue.

Using the same cartesian approach, they can now raise and lower the laser slightly using the already-present Z-axis motion system. This causes the laser spot to either grow or shrink slightly. We’re told the spot can be as much as 50% larger. This new feature is essentially a software change.

What they can then do in software is instruct the machine to enlarge the laser spot and at the same time either increase laser power or slow down the speed. This enables the machine to sinter a wider path of powder than before. This could be particularly useful for quickly solidifying the unseen interior of a part, whereas the finer laser spot could be used for external detail surfaces.

Gomez explained to us that this new approach can hit approximately 90% of the print speed of a galvo laser 3D printer, yet maintains a relatively low cost.

I’d say that is quite innovative, and cost beneficial too: galvo speed at cartesian pricing.

Via Xact Metal