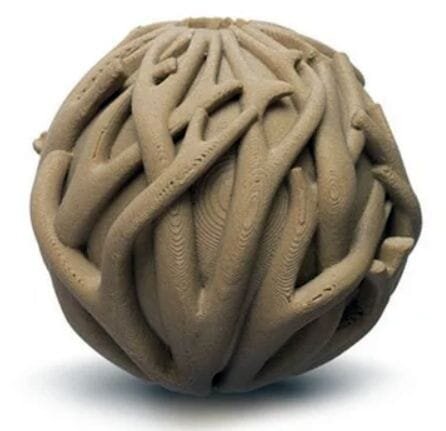

![Are layer lines on 3D prints all that bad? [Source: Slant 3D]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08c94310ea.jpg)

Layer lines are the bad news of 3D prints. Or are they?

A fascinating post by Slant 3D examines the concept of layer lines and turned my understanding of the “problem” completely upside down.

Slant 3D is an Indiana-based 3D print service that focuses on manufacturers seeking prototyping or volume production of 3D printed parts. They also provide design services before 3D printing, and fulfillment services afterwards.

For most of us involved in 3D printing, layer lines are bad. They are unsightly. They visually remind us that 3D printing is “less effective” than the proper manufacturing processes, which present polished-smooth surfaces.

Why Are Things Smooth?

Slant 3D points out the reason why most parts seen have smooth surfaces: it’s because they were made with injection molds, casting or stamping. Here’s the key statement:

“Molds are smooth because they have to be.”

And:

“Smooth parts are a result of limited engineering. Not of actual design. We like smooth parts because we have always had smooth parts. Not because we chose to have parts with a smooth surface finish.”

Thus our experience – until 3D printing – was that production parts would necessarily be smooth! We have all come to expect this is a fundamental truth: Production Parts Must Be Smooth.

But it’s wrong.

Smooth Surface Texture Bias

Slant 3D correctly points out that there is often no functional reason for having smooth surfaces. Smooth surfaces might be truly necessary in only certain situations:

-

To provide a fit with other parts

-

To provide a smooth surface for tactile contact

-

To provide light reflection

And perhaps a few others. If you think about it, many of the parts used in today’s machines would work just as well with rough surfaces. Or layer-lined surfaces.

We’re all biased towards smooth, shiny things, and we have to stop that.

Leveraging 3D Printed Textures

Slant 3D’s post explains that surface textures pose significant difficulties when using molding processes, yet they are trivial to produce using 3D printing. They’ve provided a number of interesting examples where “layer lines” have been visually eliminated through precision use of 3D printable textures.

In many cases these textures can make the end-use part even more functional. You might be able to include a rough texture on a handle to immediately increase gripping power, for example. With a traditionally made part you might have to do that in two separate parts, complicating the process.

I encourage you to read the Slant 3D article, as it will no doubt change your thinking on layer lines and surface textures.

Layer lines are a feature to be exploited, not an undesirable outcome.

Via Slant 3D