![3D parts undergoing fire resistance testing [Source: Origin]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08cf58ed60.jpg)

3D printer manufacturer Origin announced a new Loctite resin that meets aerospace fire safety standards.

Origin is a new 3D printer startup based in San Francisco, which began in 2015. They operated in stealth mode until earlier this year when they suddenly revealed some details of their mysterious but powerful P3 3D printing process.

Henkel 3D Print Materials

Now they’ve announced the product of work with Henkel’s Loctite subsidiary, which you may not realize is now a notable provider of 3D printing liquid photopolymer resins. Henkel’s Loctite brand has leveraged their skills in chemical adhesives to produce a fully-stocked line of 3D printing resins.

![Fire resistant parts produced on the Origin 3D printer in Loctite 3955 material [Source: Origin]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08cf5d6d1e.jpg)

The new product is called “Loctite 3955” and its most notable feature is that it meets stringent fire safety standards. They explain:

“The new photoreactive material that will be presented during the Formnext in Frankfurt meets the fire safety standard UL’s 94V-0 and the industry leading aerospace 12 and 60 second vertical burn tests. The innovative product sets a new threshold for fire resistance 3D printing materials across many industries, including aerospace, automotive and transportation.”

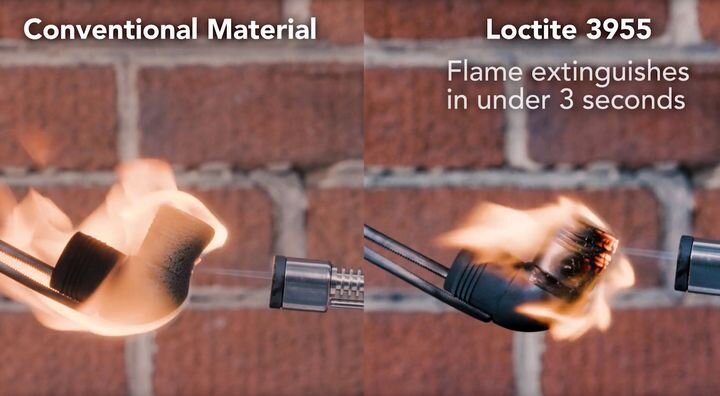

Does it work? Just watch this video to find out:

Loctite 3955 Fire Resistance

It seems that the material does become aflame, but only for a second before it naturally extinguishes itself.

Origin’s P3 3D printing process may be at work here. The P3 approach involves what seems to be a feedback loop between sensors and 3D printing operations to finely tune every aspect of printing in real time. The company boasts of being able to handle virtually any kind of 3D printable resin and achieve outstanding print results due to their P3 process.

It may be that P3 is the only 3D printing process able to technically handle Loctite 3955. It’s not stated by either company, but it’s quite possible the new material may also be only available to Origin clients. Many 3D printer manufacturers are now making exclusive arrangements with chemical companies to gain access to sophisticated materials.

Melting 3D Printer Resin?

![A solid block of resin apparently melting in an Origin 3D printer [Source: Origin]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08cf61ca00.jpg)

There’s also something very strange in Origin’s video. There is a scene where a technician places a solid chunk of dark material in an Origin 3D printer’s resin tank. Normally, one would pour a liquid photopolymer resin into the tank. But not in this video: it’s a block of material.

Then the video shows, perhaps in a time-lapse, the block melting into a liquid within the Origin resin tank, whereupon 3D printing commences. This is not explained, and I’ve never seen resin delivered to SLA/DLP 3D printers in this manner. It seems to require the 3D printer to heat the block significantly until it melts. I have to find out more about this aspect of Loctite 3955.

Fire Resistant Aerospace 3D Printing

The resulting 3D prints are indeed fire resistant, which could open the door for SLA/DLP 3D printed parts in certified aerospace applications. Presently this is done mostly with filament extrusion or metal 3D printing processes, which have some limitations. By opening the door to photopolymer materials, Origin could be creating a whole new world of 3D printed aerospace applications.