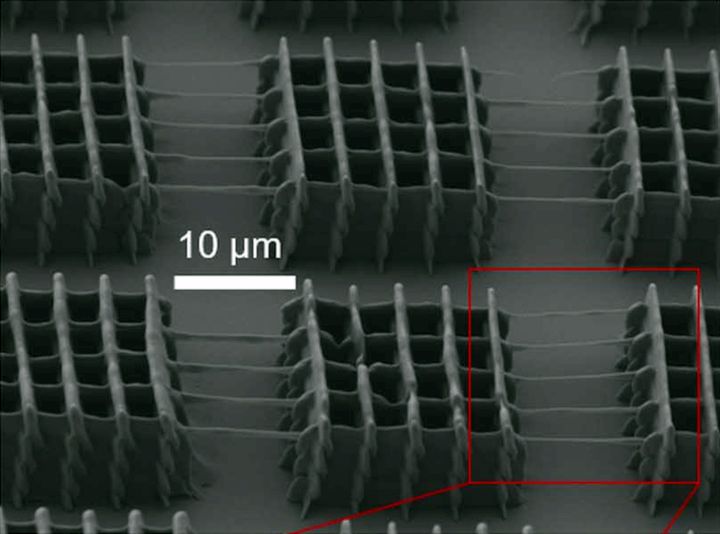

![Parallel two-photon lithography orint example [Source: Science]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08f0bcf07b.jpg)

Researchers have developed a way to very rapidly 3D print tiny objects.

Nanoscale 3D prints are not a new thing; they’ve been around for a while and use something called “two photon lithography”. This is an unusual process that I should explain before we go further.

Resin 3D Printing

Normally, a resin-based 3D printer simply accepts energy from a light source such as a laser or a pixel from a DLP or LCD source. This energy hits the surface of a vat of photopolymer resin and causes solidification. By adjusting the print position, it’s possible to 3D print whole objects, layer by layer.

The two-photon lithography approach is a bit different.

As you might imagine, the conventional resin printing process limits the minimum size of a structure to the diameter of the laser or dimensions of the light pixel, depending on which process you are using. These are small dimensions, but nowhere near nanoscale ranges.

Two-Photon Lithography Explained

In order to achieve polymerization of very small structures, two-photon lithography uses a focal technique, as seen here:

![Parallel two-photon lithography process [Source: Science]](https://fabbaloo.com/wp-content/uploads/2020/05/parallel-tpl-process_img_5eb08f0c1da93.jpg)

The laser energy is focused to a very small point using optical techniques. Note that before and after the point of focus, the laser energy is dispersed. In other words, the energy is highest at the point of focus and less elsewhere.

The trick here is to modulate the laser energy to match the polyermization threshold for the specific resin. It’s tuned so that energy sufficient for solidification occurs only at the focal point.

Thus you have a kind of “pinpoint solidifier” that can be moved about the resin — in three dimensions — to gradually create the object. Unlike traditional resin 3D printing, the solidification occurs deep within the resin. “Deep”, in this case, meaning a millimeter or so, as this is all relative.

This is called “spatial and temporal focusing”.

However, this process is rather slow to execute in practice, as the entire structure of the object must be tediously traced by the “pinpoint”. Therefore two-photon lithography cannot be practically used for mass production of small objects.

But that could change with the new research, which takes the two-photon lithography process much further by parallelizing the energy distribution.

Parallelizing Two-Photon Lithography

But how, exactly is this done? They explain:

“We generated near-infrared femtosecond pulses with a broad wavelength spectrum (approximately tens of nanometers) with our laser source that provided the light to drive the writing process. We patterned the light beam by illuminating the digital mask, which was an array of individually switchable micromirrors.

The intensity of light emerging from a micromirror along a predetermined direction was high when switched on and low when switched off. We then collimated the diverging beam that emerges from the DMD. The collimated beam passes through the objective lens and was focused onto a plane inside the photopolymer resist material.

When projected onto the image plane, the switched-on points from the DMD had light intensities above the polymerization threshold, writing a pixelated image of the digital mask in the resist. This image contained distinct or overlapping cured voxels. We fabricated 3D structures by moving the focused image plane relative to the resist with motion stages.“

Two-Photon Lithography Speeds

![Parallel two-photon lithography orint example - shown on a penny! [Source: Science]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08f0c5c06e.jpg)

Thus they are able to essentially perform two-photon lithography with an entire layer at each pass, rather than pixel-by-pixel. This is similar to the difference in speed in a conventional resin 3D printer between a laser device (SLA) and a layer device (DLP or LCD).

They say they are able to increase the speed of printing by “two or three orders of magnitude”. That’s very significant, and could lead to the eventually commercialization of the technology.

It’s possible in the future we may see mass manufacturing of micromachines of many types.

Via Science