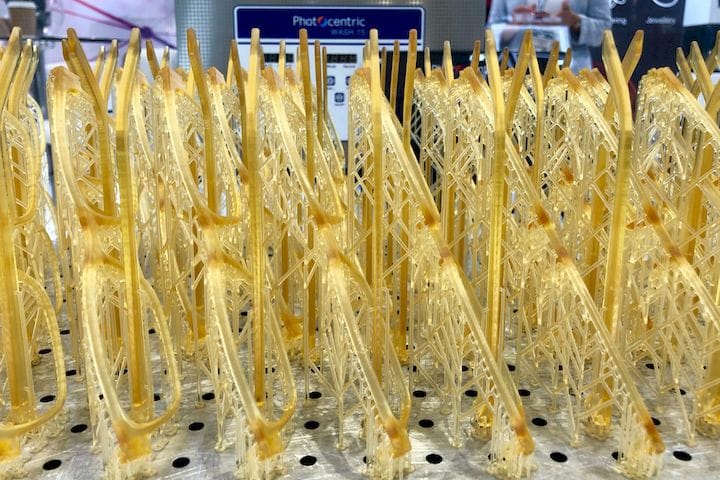

![A huge 3D print of 36 eyeglasses by Photocentric [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08f2462108.jpg) A huge 3D print of 36 eyeglasses by Photocentric [Source: Fabbaloo]

A huge 3D print of 36 eyeglasses by Photocentric [Source: Fabbaloo]

I had a chat with representatives from Photocentric and learned of their interesting industrial strategy.

Photocentric, you might recall, is one of the world’s few source manufacturers of photopolymer resin. Their white-labeled resin products are rebranded and marketed by countless resin providers across the globe.

Photocentric 3D Printers

But in recent years the company has branched into the manufacture of 3D printers themselves. We first encountered them a few years ago at CES, where they presented small desktop devices.

That’s all changed now, as they are focusing on rather large-sized resin 3D printers, such as the Photocentric Maximus.

You might think it is a straightforward matter to build a great 3D printer and then expect customers to come forward and purchase one. Well, that’s not the case at all, and Photocentric is executing an interesting strategy to overcome this challenge.

Like any smart 3D printer manufacturer, Photocentric is focusing directly on the needs of clients. 3D printer operators actually don’t want 3D printers; no, instead they really want the prints that come out of them. The 3D printer is the means to that end.

And I should add, the material is an important part of that equation. A 3D printer plus material equals an object, more or less.

Photocentric Customer Feedback

That’s why Photocentric is trying to work closely with companies to more deeply understand their manufacturing needs. It’s a process of feedback, and it is quite challenging to do.

The objects intended to be produced must have certain engineering properties, and those are derived from the original resin material and the printer that produces the object. Photocentric is working with several clients to tweak material formulations to more correctly address specific client needs.

Photocentric Resins

So far, they’ve produced materials for investment casting, high-temperature materials, UV-resistant materials and more.

The key is to produce a combination of machine and material that enables the manufacturing client to operate profitably. With traditional manufacturing gear, some manufacturers turn away prospective customers because the costs of making the required objects is not profitable, usually because the cost of tooling is excessive for the job.

But with 3D printing there is no need for tooling as objects can simply be 3D printed on demand. However, the catch is that they must be made in a material that matches the engineering demands of the particular situation. That’s where Photocentric believes they can add value.

By creating the right kinds of resin materials, they could potentially unlock a lot of business for such manufacturers, business they might have previously turned away. If they’re successful, they could open up a large market for their products.

Photocentric Partners

But it’s challenging to find clients that are willing to work iteratively with a provider in this way. Photocentric has several partners now, but is seeking new partners to test their materials and provide detailed feedback.

If you’re a manufacturer and interested in this concept, you might want to give Photocentric a call.

Via Photocentric