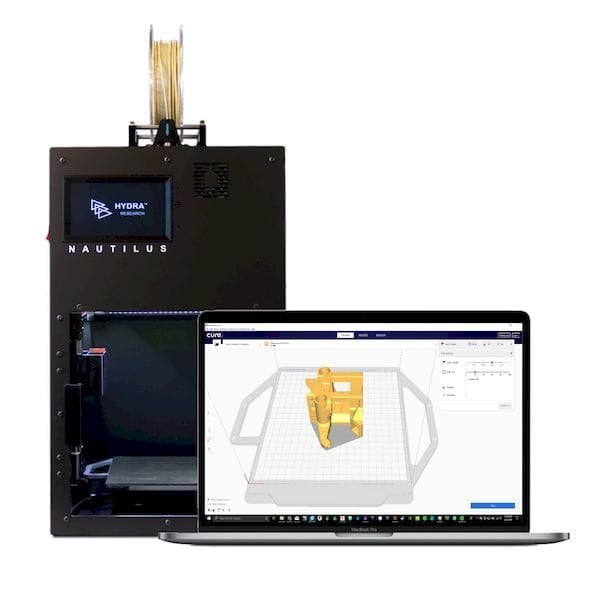

![Hydra Research’s Nautilus 3D printer [Source: Hydra Research]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08ef6755ef.jpg) Hydra Research’s Nautilus 3D printer [Source: Hydra Research]

Hydra Research’s Nautilus 3D printer [Source: Hydra Research]

I’m looking at the Nautilus open source 3D printer from Hydra Research.

Portland-based Hydra Research has been working on the Nautilus for some time, but the company is now offering the machine to the public after a “successful pre-order campaign”.

The Nautilus enters a very competitive market for desktop 3D printers, and Hydra Research’s strategy is to include a number of practical ease-of-use features and high-quality components in the design.

Nautilus 3D Printer

![Three of Hydra Research’s Nautilus 3D printers [Source: Hydra Research]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08ef6b70c5.jpg) Three of Hydra Research’s Nautilus 3D printers [Source: Hydra Research]

Three of Hydra Research’s Nautilus 3D printers [Source: Hydra Research]

The Nautilus, which includes a reasonable build volume of 205 x 205 x 220 mm, includes a removable magnetic spring steel print plate that should make it very easy to remove every print. The company says they intend to offer different types of print plates to match the print materials, but as of now they have two coatings available: BuildTak PEI and BuildTak Original.

Unlike most open source 3D printer designs, the Nautilus includes an entirely enclosed build chamber. This feature should capture stray heat from the hot end and build plate to decrease thermal gradients and reduce the possibility of print warping.

One of the Nautilus’ key features is an easily swappable toolhead. They currently offer two toolheads, the X 400 Tool Cartridge, which is the default, and the B 250 Tool Cartridge, which is for higher levels of detail. I suspect the latter includes a 0.25mm nozzle, rather than the standard 0.4mm nozzle diameter. If the Nautilus proves successful, it’s likely that Hydra Research will produce additional cartridges for further material functionality.

![A very small 3D print by Hydra Research’s Nautilus 3D printer [Source: Hydra Research]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08ef6e967f.jpg) A very small 3D print by Hydra Research’s Nautilus 3D printer [Source: Hydra Research]

A very small 3D print by Hydra Research’s Nautilus 3D printer [Source: Hydra Research]

E3D-Online Nozzle X

I should note that the X 400 Tool Cartridge includes E3D’s “Nozzle X”, which is a very powerful steel nozzle that resists abrasion from materials such as carbon fiber, but also includes the useful feature that stray material will not stick to it!

Nautilus 3D Printer Features

Like most machines these days, the Nautilus includes a filament-out detector, so you won’t ruin overnight prints on a short spool. There’s also a power recovery mode that will restore your print when power is restored after a failure.

![A 3D printed nylon carbon fiber part by Hydra Research’s Nautilus 3D printer [Source: Hydra Research]](https://fabbaloo.com/wp-content/uploads/2020/05/nautilus-Example2BY2BBack2BNylon2BCF152B28150029_img_5eb08ef733ac2.jpg) A 3D printed nylon carbon fiber part by Hydra Research’s Nautilus 3D printer [Source: Hydra Research]

A 3D printed nylon carbon fiber part by Hydra Research’s Nautilus 3D printer [Source: Hydra Research]

But there’s one rather interesting feature I haven’t seen on other machines. They explain:

“Crash detection — eliminates layer shifts by monitoring motor load and correcting the position of the tool head if a motor loses its position.“

I’m not sure how this works, but it sounds good. Could they be using a closed loop approach here?

The Nautilus includes a fancy color touchscreen, and a WiFi connection to allow for remote submission and control of print jobs.

![A 3D printed Pi case in vinyl material by Hydra Research’s Nautilus 3D printer [Source: Hydra Research]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08ef77a6e8.jpg) A 3D printed Pi case in vinyl material by Hydra Research’s Nautilus 3D printer [Source: Hydra Research]

A 3D printed Pi case in vinyl material by Hydra Research’s Nautilus 3D printer [Source: Hydra Research]

Nautilus 3D Printer Ease of Use

One thing I am very impressed with is Hydra Research’s attention to operator success. For example, they’ve put a module in the Cura marketplace that includes print profiles for the machine.

They also provide a very extensive and easy-to-use section on their website that advises operators in detail in four areas:

-

3D Print Quality Troubleshooting: A detailed visual guide to typical print failures and what to do about them.

-

Design Rules for FFF 3D Printing: A set of sixteen design rules for various geometries, including threading, horizontal holes, pins and other commonly challenging design features.

-

Advanced Cura Slicing: Ten ways you can use Ultimaker Cura slicing software to handle unusual 3D printing scenarios.

-

Material Guide: A set of eight guides for specific types of materials, such as flexible, ABS, HIPS, etc.

The Nautilus is priced at US$2,500.

Via Hydra Research