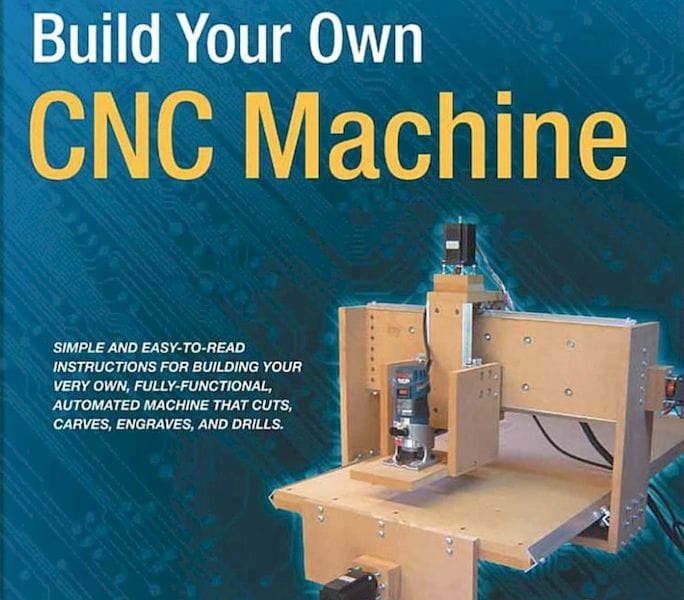

![Build your own CNC machine [Source: Amazon]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08f9d1169b.jpg) Build your own CNC machine [Source: Amazon]

Build your own CNC machine [Source: Amazon]

This week’s selection is “Build Your Own CNC Machine” by Floyd Kelly James and Patrick Hood-Daniel.

A “CNC machine” is a milling device, not a 3D printer. In some ways, it is the opposite of the 3D printer. 3D printers add material to create objects, while CNC machines — and many other traditional tools — subtract material to create objects.

What James and Hood-Daniel describe in this book is in fact a small milling machine, where a rotating bit can move by digital command to precision mill a desired object from a chunk of bulk material. This is a very common making machine, and is found in sizes ranging from the hobby level (which is what this book is about), to enormous industrial milling machines.

Nope, this book is not about 3D printing. But there are several reasons why I think it’s a worthwhile tome for Fabbaloo readers.

First, it’s a building project that many of our readers will enjoy executing. Many people own 3D printers simply to make parts for their own inventions.

Secondly, while the book attempts to build the CNC machine from wood components, it might be possible to 3D print several of the parts, making it an interesting challenge for 3D print-experienced readers. Which parts could be 3D printed? Will they work? An interesting challenge, indeed.

But I think the true value of this project is one of perspective. Those of us in the 3D printing world often focus strongly on our technology as if there were no others. In fact, 3D printing is merely one of dozens of usable making processes.

The best path is to choose the most appropriate technology for the job. Usually, it is not 3D printing, as most objects are relatively simple in geometry and can be made with other traditional making processes. Choose the optimum process and you might get a better result, and faster too.

By building your own CNC machine and getting it operational, one could far more deeply understand the uses — and misuses — of CNC making technology. Thus I believe that a 3D printer operator who was also familiar with CNC technology would be a better maker, able to make better decisions about production of a given part.

I suspect a reader of this book would also gain a deeper appreciation for 3D printers, ironically. It turns out that the CNC machine design used by the authors is cartesian, meaning it has three axes: X, Y and Z. The CNC machine will move along these axes to access all parts of the material to be milled.

That’s precisely what many 3D printers do: a cartesian system of movement. Only the toolhead is different. Note — this is why many small 3D printer manufacturers offer multi-tool machines: it is relatively easy to switch toolheads in such a configuration.

You’ll soon realize all this and more if you read this book.

Via Amazon