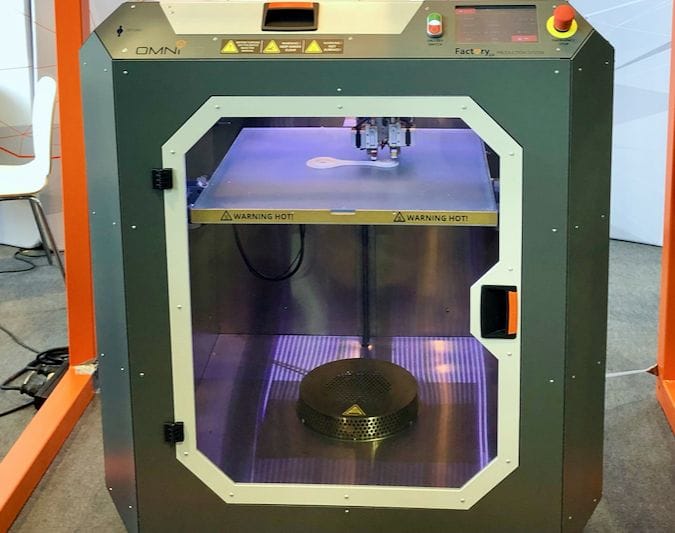

![The new Omni3D Factory 2.0 industrial 3D printer [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09f965c0db.jpg)

Omni3D’s new Factory 2.0 industrial 3D printer has some powerful features.

The Polish company has been manufacturing an industrial-quality 3D printer for several years now, which we believe they’re using to target Stratasys Fortus customers. The Factory 2.0 machine includes many of the features found in the Fortus equipment, but may have lower operational costs.

While their latest machine iteration includes the same generous 500 x 500 x 500 mm build volume, there are some new features.

One is that the machine now includes explicit heating to 70C. In other words, the machine now includes active heating as opposed to collecting stray heat from the heated print bed. The Factory 2.0 calibrates itself fully automatically.

One new feature is a height-changing extruder. We’ve seen this before on a few select machines, but it is quite useful. When two nozzles are present, it is possible for the inactive nozzle to knock over the print if there happens to be a small amount of material sticking up above the build plane. With Omni3D’s new toolhead, the inactive nozzle is moved slight out of the path to troubles, making printing more reliable.

The internals of the Factory 2.0 have been upgraded to industrial-grade mechanicals. This will have several effects, including better quality prints, longer machine life and increased operational reliability.

They’re also including a networking feature that will allow an organization to effectively manage a small farm of Omni3D printers.

The Factory 2.0 machine is designed to 3D print strong engineering materials. In order to demonstrate the power of these materials, Omni3D arranged to 3D print a small hook made from carbon fiber material support the weight of a complete Omni3D Factory 2.0 printer!

![A tiny 3D printed loop holds up a 180kg 3D printer [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09f96be77c.jpg)

As you can see, this small loop was able to support the 180kg weight of the large printer.

![A tiny 3D printed loop holds up a 180kg 3D printer [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09f970dcef.jpg)

Omni3D also is working towards releasing a new machine in January, the Omni3D Lite. It’s quite similar in structure to the flagship Omni3D Factory 2.0 machine, but it does not have a separate chamber heater and is thus able to 3D print only more basic materials. It’s priced at approximately €12K (US$13.7K).

![The upcoming Omni3D Lite industrial 3D printer [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09f9755319.jpg)

Omni3D is also introducing their own line of materials. It’s not that they are switching their equipment to accept only proprietary materials; no, the machine will continue to be open to any materials. However, Omni3D will provide precise machine settings to ensure optimum 3D print results when using their own filament products.

This is an approach that is increasingly being used by vendors torn between the precision of controlling the entire process and opening up a machine for experimentation. It’s the best of both worlds.

Via Omni3D

FELIXprinters has released a new bioprinter, the FELIX BIOprinter, which is quite a change for the long-time 3D printer manufacturer.