![The Admatec ADMAFLEX 130 ceramic 3D printer [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09e56e382f.jpg)

Admatec produces powerful ceramic (and metal) 3D printers.

The Netherlands-based company began in 2013 as a spin-off of an injection molding company, to focus on the development of ceramic 3D printing. They have succeeded and since 2016 offer a number of different models able to produce very fine ceramic 3D prints.

Today they offer four different machines, most of which use a DLP process to transform custom liquid resin into ceramic 3D prints.

While there are a few ceramic 3D printers on the market, these machines are a bit different: they have been very carefully engineered to produce prints of exceptional quality using a variety of ceramic materials. Apparently their in-house ceramicists total over 150 years of experience.

![Ceramic 3D prints [Source: Admatec]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09e5780bb6.jpg)

Today they offer several materials including Aluminum Oxide, Zirconium Oxide, Fused Silica, Alumina Toughened Zirconia, and Silica based materials for investment casting. They’re also working on Hydroxyapatite material, a calcium phosphate that apparently could be used as a bone substitute.

The machines are “open materials”, meaning that it is possible for operators to explore the use of other resins, perhaps of your own design. However, you’d have to develop your own print settings as Admatec can’t provide them.

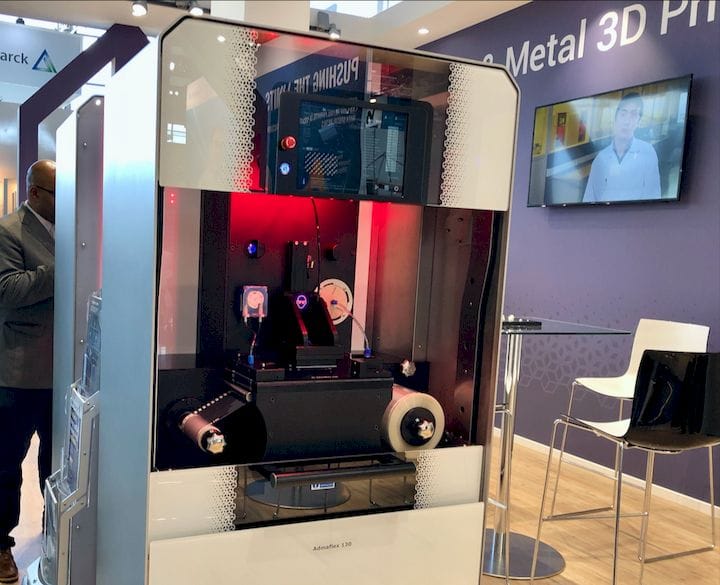

![Inside the Admatec ADMAFLEX 130 ceramic 3D printer [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09e57d7ee7.jpg)

Admatec’s printing process is multi-step, as you may have guessed. They first 3D print the object using the resin/DLP or SLA process to create a green part that includes binder. This is then transformed into a brown part by de-bindering. The brown part is then sintered into the finalized ceramic part.

The results are quite good. Admatec explains:

”Since the development of the functional AM process in 2012, we have applied the ADMAFLEX technology for supplying actual industrial parts with critical specifications like mechanical strength, tolerances and throughput times as a commercial ‘jobshop’ part service. The ADMAFLEX 2.0 series hugely accelerated the technology’s maturing curve and span of applicability. All lessons learned are concentrated in the first commercial available machine, the ADMAFLEX 130.”

One of their machines, the Admatec ADMAFLEX 130, offers a build volume of 96 x 54 x 120 mm, suitable for small industrial ceramic parts. This machine is priced around €125,000 (US$143K). We’re told there is also a larger machine, the 300 model, priced at around €300,000 (US$342K).

Admatec offers a complete solution, as they market more than simply the 3D printers and associated materials. They also offer a line of furnaces that can be used to sinter the completed parts in a fully compatible way.

Another machine marketed by Admatec is their interesting Laserflex Conflux system for 3D printing metals in a green/brown process. This, unlike their other equipment, uses a powder-bed fusion approach rather than the liquid resin system. However, they have some interesting twists in how it works.

The problem is that in typical powder bed fusion systems the layer recoating process often yields a rather rough surface for fusing. Admatec’s advantage here is to mix a liquid into the powder. Then after the layer is recoated, they allow it to dry and compact. Of course they do heat the print surface to speed the drying process, but I suspect this step does slow down the printing somewhat. This results in a far smoother surface for fusing, and consequently, finer print resolutions.

Admatec explains that the Laserflex Conflux is priced at around €200,000 (US$228K).

For finely detailed ceramic 3D prints, you might want to look at Admatec’s line of equipment. They do offer international resellers, and even have support offices in China and the US.

Via Admatec

FELIXprinters has released a new bioprinter, the FELIX BIOprinter, which is quite a change for the long-time 3D printer manufacturer.