Charles Goulding and Preeti Sulibhavi of R&D Tax Savers discuss the use of 3D printing in space launches.

Automating Space Travel: Small Rockets Launching into Action

Space travel has been elusive, even for the select few who are trained and tested to undergo the journey. Several space launch firms are actively changing this dynamic. A new era of global spaceports launching small rockets is within reach. This is largely in part due to several major new space industrial startups and savvy technology entrepreneurs. Space travel is now within orbit.

Rocket Lab

“Opening access to space to improve life on earth,” Rocket Lab’s mission has been to develop and launch advanced rocket technology to provide rapid and repeatable access to orbit for small satellites. As recently as November 11, 2018, Rocket Lab was responsible for the first commercial launch by an American-New Zealand company.

In 2015, Rocket Lab developed the world’s first battery-powered rocket, the Electron rocket. It now incorporates a 3D printed Rutherford engine, aiming for outer space. The engine is almost entirely made via additive manufacturing, which saves engineers time, reduces weight and ultimately streamlines production at lower cost. Because of the efficiency of the 3D printed Rutherford engine, which is 50% more efficient than traditional gas-powered engines, the rocket reached space in only 3 minutes. The rocket and its payload were not able to make it into orbit, but that has not hindered Rocket Lab’s position to accelerate the commercial phase of this program. Its new production facility, unveiled on October 12, 2018, would be the optimal place to establish 3D printing production technologies.

SpaceX

The key to making human life multi-planetary is reusability. This is according to Elon Musk’s SpaceX, a space launch firm that developed the world’s most powerful rocket: Falcon Heavy. Falcon Heavy is unique in design in that it minimizes stage separation events and maximizes reliability. Additionally, its engine can be restarted multiple times to place payloads into a variety of orbits.

Use of 3D printing or additive manufacturing can offer improvements over traditional manufacturing methods in that rocket parts are more robust and of highest performance. In late 2013, SpaceX 3D printed a SuperDraco Engine Chamber as part of its crewed spaceflight program and the Dragon Version 2 vehicle. Developed entirely in-house, the engine boasts a revolutionary launch escape system; the spacecraft can land propulsively and is able to be reusable and flown on multiple trips, thereby reducing the cost of space travel.

On January 6, 2014, SpaceX launched Falcon 9, which contained a 3D printed Main Oxidizer Valve (MOV) body in one of the nine Merlin 1D engines. The valve operated successfully under high pressure liquid oxygen, high vibration, and cryogenic temperatures. SpaceX found that compared to a traditionally cast part, a 3D printed valve body has improved strength, ductility, and is fracture resistant with a lower variability in materials properties. The MOV body was printed in less than two days as opposed to taking months with traditional manufacturing. SpaceX’s test program has since qualified the 3D printed MOV body to fly interchangeably with cast parts on all Falcon 9 flights going forward.

Virgin Orbit

“On a mission to open space for everyone,” Virgin Orbit aims to connect us across vast distances. Propelling human curiosity to new heights, Virgin Orbit, a division of Richard Branson’s business, develops the launch process into phases as listed below.

-

Phase 1: Pre-Launch Process

-

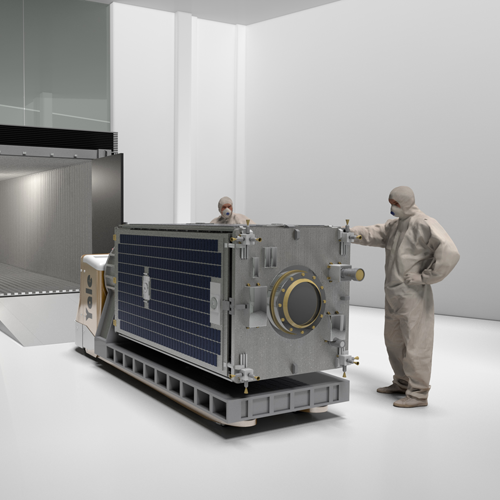

Phase 2: Payload Processing

-

Phase 3: Rocket Transport to Launch Site

-

Phase 4: The Launch Process

In Long Beach, CA, Virgin Orbit’s 180,000-square-foot manufacturing facility is producing rocket parts using the Lasertec 4300 3D additive-subtractive hybrid machine. The room-sized machine builds components from the ground up, using laser light that fuses metal powder into each layer. The first of its kind in operation within a commercial company, Virgin Orbit is using 3D printing to make the process of building rocket engines and other spacecraft components more efficient.

Vector Launch, Inc.

“Get launched with Vector,” is how Vector gets those interested in launching signed up for either commercial or government funded satellites. Their goal is to get more payloads to more destinations more efficiently. 3D printing has enhanced its rapid launch capability and has offset any heavier mass to orbit launches.

In 2017, the Vector-R Launch Vehicle featured a 3D printed engine injector that is customized to carry small payloads into space. The engine injector was printed in just one piece, instead of multiple pieces that are later pieced together, cutting down on potential errors, points of friction, as well as overall time and cost of manufacturing.

Firefly Aerospace, Inc.

“Making space for everyone,” and economizing the small satellite launch, Firefly offers an orbital transfer vehicle (OTV), and various launch cadences such as alpha, beta and gamma. With various launch site facilities, both launch vehicle and multiple manifest customers will be pleased. In early 2018, Firefly Aerospace opened Firefly Ukraine, an R&D facility equipped with the largest 3D printer in Ukraine. This 3D printer will be used for industrial manufacturing of high-quality metal parts. The 3D printer expands the team’s capability to design and manufacture original launch vehicle and systems components. Its recent Commercial Payload Services contract with NASA, announced on November 29, 2018, would benefit from establishing 3D printing in the commercial production process from the onset.

Gilmour Space Technologies

Raising millions of dollars, Gilmour Space Technologies offers low-cost, small satellite launches and rideshares with frequency and reliability. Gilmour’s proprietary hybrid rocket line of FlexLine carbon composite products is the first of its kind in Australia. Gilmour leverages proven expertise, while lowering launcher development costs and time-to-market. Its FlexLine products offer weight optimized, reliable and user-friendly solutions, at relatively low cost. 3D printing could improve the accuracy of its lightweight solutions.

In 2016, Gilmour successfully tested 3D printed fuel for space-bound rockets. They have been experimenting with 3D printed fuel made from two different materials to make space exploration more efficient. With this 3D printed proprietary rocket fuel, Gilmour is effectively reducing the cost of each launch. The 3D printing system allows Gilmour to produce a low-cost, highly efficient solid rocket fuel. A small launch that once cost $15 million can now cost about $5 million.

The use of 3D printing has been the driving force behind much advancement in this highly complex industry.Space launch firms with innovative efforts aimed at advancing new approaches to spaceflight, exploration and discovery can benefit from R&D Tax Credit incentives.

The Research & Development Tax Credit

Enacted in 1981, the now permanent Federal Research and Development (R&D) Tax Credit allows a credit that typically ranges from 4%-7% of eligible spending for new and improved products and processes. Qualified research must meet the following four criteria:

-

Must be technological in nature

-

Must be a component of the taxpayers business

-

Must represent R&D in the experimental sense and generally includes all such costs related to the development or improvement of a product or process

-

Must eliminate uncertainty through a process of experimentation that considers one or more alternatives

Eligible costs include U.S. employee wages, cost of supplies consumed in the R&D process, cost of pre-production testing, U.S. contract research expenses, and certain costs associated with developing a patent.

On December 18, 2015, President Obama signed the PATH Act, making the R&D Tax Credit permanent. Beginning in 2016, the R&D credit can be used to offset Alternative Minimum tax for companies with revenue below $50MM and for the first time, startup businesses can obtain up to $250,000 per year in payroll taxes and cash rebates.

From Prototype to Production

Space launch firms are no longer building prototypes for testing. They are launching small rockets for commercial purposes. The process can achieve greater automation and improved production with the help of 3D printing. Materials should be lightweight, durable and allow for mathematical topology for special design features. If 3D printers are utilized from the onset, the process can be efficient and seamless, as opposed to transitioning after beginning the commercialization process. Obviously, these space launch firms and their commercial partners are excellent candidates for the R&D Tax Credit and should take advantage of such tax incentives.

Years of experimentation are leading to affirmation: 3D printing in space, for in-space use, is looking viable.