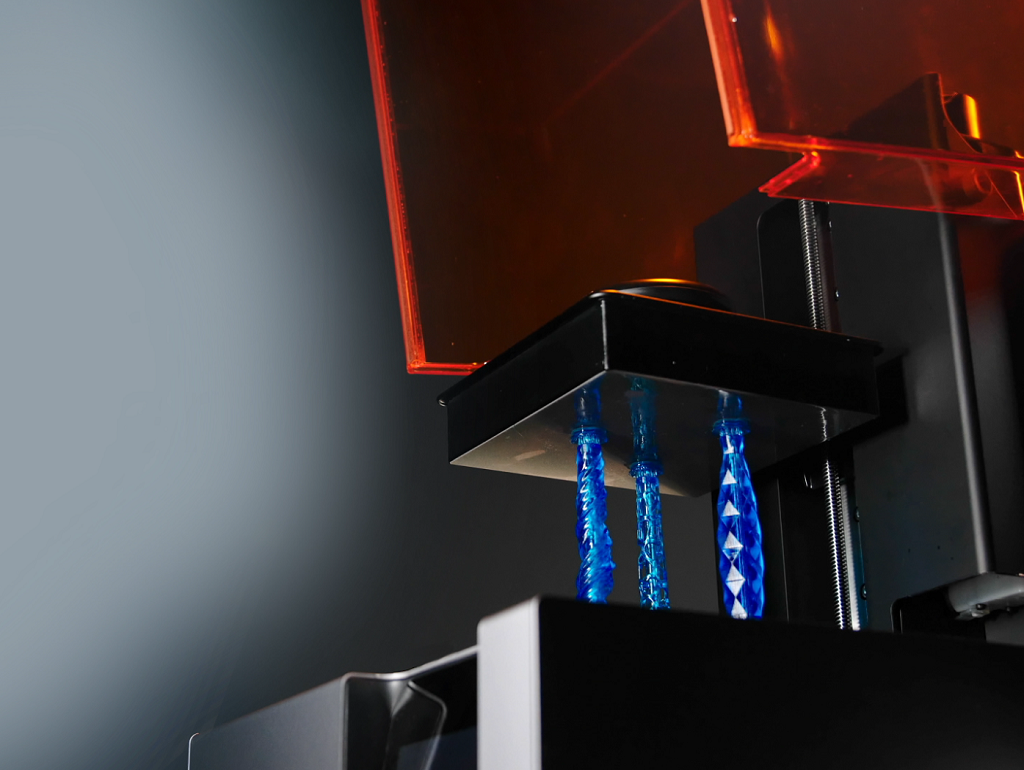

![Gillette Razor Maker handles being 3D printed on a Form 2 [Image: Formlabs]](https://fabbaloo.com/wp-content/uploads/2020/05/Formlabs2BGillette2BRazorMaker2B28129_img_5eb09eb28cce4.png)

As additive manufacturing plays an ever-larger role in the business world, many major companies are building their own internal startups.

3D printing startups have deep roots in this industry. Many of the best-known brands in the business trace their beginnings to garages, Kickstarter campaigns, and after-hours projects that escalated into successful companies. Born out of incubators, makerspaces, universities, these startups’ humble origins showcased the DIY nature of especially the desktop 3D printer space. And startups are still a big deal — but how they start up is a different story.

Major global brands have been entering the 3D printing space, or finally going public about their investments into the technology. To best build what’s clearly an important strategic focus in a maturing advanced manufacturing space, an increasing number of these companies are establishing their own 3D printing businesses.

These new businesses are run almost as startups, with collaborative work environments, exploratory projects, R&D, and brainstorming sessions. They do have a major difference from some of the earlier independent startups, though, in terms of the resources behind them.

On the hardware side, several big names in 2D printing have leveraged their expertise to take on 3D printing. HP may be the most familiar example right now, as first Multi Jet Fusion and then Metal Jet technologies build on decades of inkjet know-how with well-funded and well-partnered new 3D printing processes. But they’re certainly not alone. Mimaki is making waves with full-color 3D printing — “full” to them meaning 10 million colors with picture-perfect matching. Also leveraging hardware know-how is global mainstay GE, which established GE Additive and in addition to focus on the portfolios of two metal 3D printing acquisitions has created its own tech and continues to work with 3D printing throughout its businesses.

Materials companies have also been increasing their focus on (and investment into) 3D printing. Some of the world’s largest plastics suppliers have established strong presences in additive manufacturing, and metal powder companies are following suit. BASF, DSM, SABIC, Solvay: all had a major presence at formnext 2018, ready to share a look at their work in this field. The first of these has been making particular headlines, as in 2017 BASF announced the intent to launch its own 3D printing business.

Software too is of course an important part of the equation. From overall mainstays like Siemens PLM to CAD favorites like SOLIDWORKS, mainstream software is increasingly focusing on additive manufacturing. Increasing capabilities are coming to popular suites like Autodesk Fusion 360, while each annual update of SOLIDWORKS features more and more for 3D printing. Some of these integrations run especially deep, as Siemens, for example, has long worked with additive manufacturing through several of its businesses and supports subsidiaries’ operations with global resources.

Some of the major companies within the industry itself are also embracing their own startup cultures via spinoffs. Evolve Additive Solutions, for example, spun off from Stratasys last year and is now operating as its own independent business to focus on a technology unique from its former parent’s portfolio.

And of course, 3D printing isn’t limited to those behind the technologies; it’s up to the applications to push the industry forward. Major projects and partnerships — think Carbon’s work with adidas for partially 3D printed shoes that are being mass manufactured — are raising the profile and availability of 3D printing. And it’s going deeper than that. With Gillette’s Razor Maker initiative, the well-known shaving brand is bringing 3D printing to bathrooms everywhere. First with Ultimaker tech and now with Formlabs’, Razor Maker is creating 3D printed razor handles designed just for each user — and the company describes the work as a sort of startup within the larger company in the latest video from Fabbaloo friend Joel Telling (the 3D Printing Nerd):

The benefits of startup mentality are many, and often boil down to one key aspect: agility. The early stages of creating a new business strategy require speed and dexterity; there isn’t time to jump through corporate hoops when moving from project to project or scrapping something that doesn’t work to explore something new that just might. Having a separate project team dedicated to a new area allows for a level of independence that enables agility in operations.

Still, those efforts can be costly, especially when they don’t work out. Time is money — but also money is money. The physical parts and labor to build a new system, test new materials on appropriate systems, and build new software platforms are by no means inconsiderable. Having access to resources is hugely helpful in building new businesses. When it comes to launch, it’s also no small thing to have pre-established brand recognition already built in; it’s human nature to trust the known.

There are negatives too, of course. Keeping up with the branding of a well-known parent, perhaps a level of hype in marketing, red tape and approvals, layers of reporting, proving the value of ongoing work… There’s a reason GE’s team didn’t initially open up to higher-ups when working on the now-famous LEAP fuel nozzle. It’s not easy to start a new project or business with nascent technologies, especially when a known name may position a company as effectively a ‘city on a hill’ where failure is public.

When it comes to more accessible areas more historically open to startups, there’s also the problem of timing. For desktop 3D printing, in particular, it may be a bit late in the game now to create a new business, especially if it’s not really differentiated in any substantial way from those already on the market. We don’t need another desktop FDM 3D printer just because.

Finding just the right strategy to take a new 3D printing business idea to market is a tricky proposal. Build something from the ground up and hope for the best? Take time in stealth to find investors and customers before public announcement? Spin off university work into a commercial enterprise? Work under the umbrella of a larger business? Each of these options, and many besides them, has shown success (and failure).

As 3D printing continues to mature as technology and industry, we’ll continue to keep an eye on the shape of entry and adoption.