![[Image: Oceanz]](https://fabbaloo.com/wp-content/uploads/2020/05/Oceanz3Dprinting-Radiolaria_LilianvanDaal_01_img_5eb0a64da784c.jpg)

3D printing the seating of the future isn’t just getting personal, it’s sustainable.

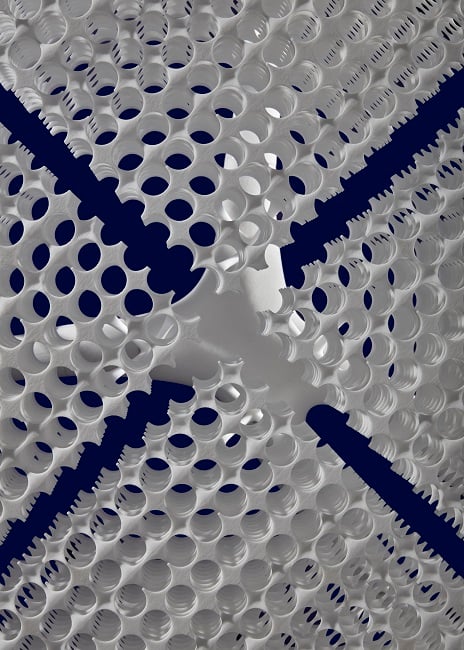

While rear-specific seating represents one increasingly popular facet of what 3D printing can offer the derrière, sitting pretty can also mean sitting green-ly with a new chair and its new eco-friendly material. Dutch designer Lilian van Daal teamed up with Oceanz to create Radiolaria #1, a beautiful follow-up to her Biomimicry Soft Seating graduation project.

Four years after the presentation of that clever 3D printed design, Radiolaria #1 highlights the evolution of not only van Daal’s aesthetic, but of the technological capabilities used to bring her vision to life.

These updates are described:

“Since the very first soft seating project, production time and energy consumption have both been decreased by 50% due to optimizations in the design that allow all elements of one chair to fit in one production run of the 3D printing machine. Novel material research conducted by Oceanz 3D printing has allowed Van Daal to use recyclable materials (Oceanz EcoPowder) for printing.”

Radiolaria and Bryozoa inspired Radiolaria #1: these unicellular organisms create complex mineral skeletons and have an unexpectedly interesting Wikipedia listing.

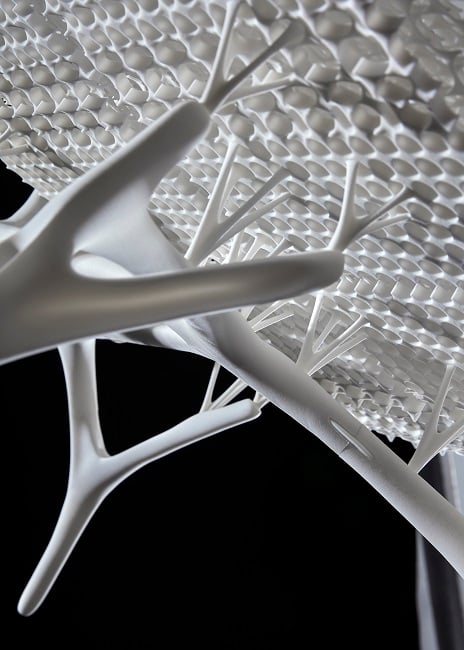

Drawing inspiration from the lattice of connections of these microorganisms, van Daal sought to create a chair that leaned on similar connections for assembly, rather than glue or other additional materials.

Working with Oceanz allowed for the design to come together (literally) in one material, with the new EcoPowder a form of recycled PA 12. According to Oceanz CEO Erik van der Garde, EcoPowder “has almost the same characteristics as the standard Oceanz PA12.” Reusing the 3D printing material significantly reduces the waste stream and enables more sustainable material processing. Oceanz has invested “a lot in research to realize a sustainable production process.”

“This makes 3D printing/prototyping a very sustainable production technique. This doesn’t only give you a good feeling, but also the functional properties of the material remain the same. The zero-waste promise is also redeemed,” he said.

Working with a low-waste product to create organic shapes brought van Daal’s latest creation closer to nature — with the latest technology.

Via Lilian van Daal and Oceanz / All images provided by Oceanz