![SOFTSHAPER 2019 interface view [Source: Verashape]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a856aa0d3.jpg)

Verashape has dramatically improved their 3D printing management system, SOFTSHAPER.

The company is known for their line of 3D printers, most notably the incredible 5-axis 3D printer they recently released, a machine capable of doing things most other 3D printers cannot imagine doing. The company is one of many 3D printer operations originating in Poland.

Their new software, SOFTSHAPER, is, like most 3D print management software: it is designed to prepare 3D models for printing by assembling a “job” and converting it into GCODE for execution by the printer. Every 3D printer company has this functionality.

But how they obtain the technology is quite a different story. Generally there are two approaches.

A company could endeavor to design and build their own dedicated software to do so. This gives the company the most control over the system, and allows them to embed features that take the greatest advantage for the peculiarities of their own equipment.

However, that approach is expensive; building a sophisticated software system is challenging, and keeping it up to date with new machine releases, new features and resolving customer issues is an ongoing commitment that some manufacturers cannot undertake. And you can’t just “do anything”; it has to be incredibly good to demonstrate superiority over competitors.

The second approach a 3D printer manufacturer could do is essentially give up and yield software options to other third parties. Many smaller companies opt for open source tools, which are pretty decent, but sometimes are hard to use. Another option is to use a paid third party tool like Simplify3D, which is quite powerful, but not free. Some manufacturers make a deal with Simplify3D to bundle the software into their machines automatically.

![Another look at the SOFTSHAPER 2019 interface [Source: Verashape]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a85718f44.jpg)

Verashape has chosen neither of these options and seems to have invented a third approach: partnering. They say:

“Thanks to the license granted by Siemens PLM Software, the manufacturer of VSHAPER industrial 3D Printers conducts programming work to create software based on Parasolid Communicator to support the import and proper preparation of models for 3D Printing. The latest version of SOFTSHAPER software, popular among other 3D printers producers as well as software users, introduces many new features and improvements.”

This offers Verashape the opportunity to customize a solution that has a huge head start by being based on an existing tool.

While SOFTSHAPER includes all the usual functions, there are some interesting features.

They use a “Process Tree” in a manner similar to how CAD systems work. It sounds like you can associate certain printing parameters with specific models that appear within a print job and manage them independently.

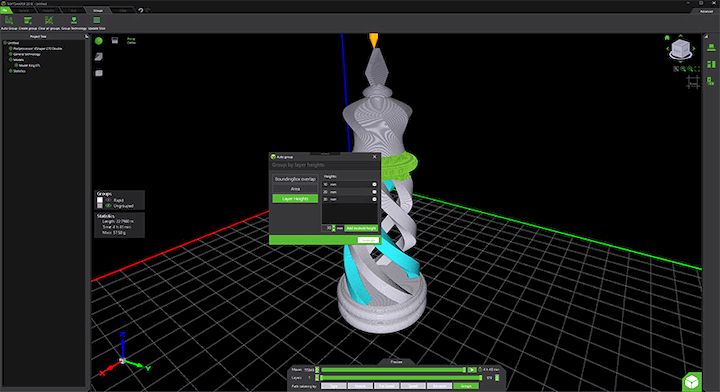

![Grouping in SOFTSHAPER 2019 [Source: Verashape]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a857651ea.jpg)

SOFTSHAPER also provides a way to group layers together in different ways. This enables an operator to, for example, make the density stronger at certain parts without affecting the rest of the 3D print. Basic 3D model slicing systems tend not to have this feature.

They provide a number of features that can be used to test the viability of your job before you expend the time and materials to run it, thus increasing quality and reliability. This includes printing simulations and the ability to view the print job in a number of different ways.

Like the view by print area type:

![Previewing a 3D print job by print type in SOFTSHAPER 2019 [Source: Verashape]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a857bdba2.jpg)

Or the view by print speed:

![Previewing a 3D print job by print speed in SOFTSHAPER 2019 [Source: Verashape]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a8581716d.jpg)

Or the view by nozzle used:

![Previewing a 3D print job by nozzle used in SOFTSHAPER 2019 [Source: Verashape]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a8585ce89.jpg)

Or the view by fan speed, something I’ve not seen previously:

![Previewing a 3D print job by fan speed in SOFTSHAPER 2019 [Source: Verashape]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a858c0f6b.jpg)

SOFTSHAPER 2019 also provides a number of different ways to manipulate support structures. This is a very important feature because I’ve been burned many times by support structures that might be ok for another model, but not the one I’m currently testing. One of the new features is a way to increase the density of support near the model.

![Portion of an extensive report on a specific 3D print job by SOFTSHAPER [Source: Verashape]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a859233fb.jpg)

There’s also a feature to print a formal report on the print job, including the parameters used, the specifications and even a top-down view of the print table. While this feature might not be for everyone, I suspect it could be of tremendous value to anyone doing iterative testing of models by varying print parameters. In that case, you’d just print the report and staple it to the model to keep track of the testing progress.

SOFTSHAPER 2019 looks like a very interesting 3D printer management software tool.

Via Verashape

MiniFactory’s new software produces a very useful report for each 3D print that may be important for clients. We had a close look at one.