![Improvements in the Bolt Pro [Source: Leapfrog 3D Printers]](https://fabbaloo.com/wp-content/uploads/2020/05/bolt-pro-improvements-ov_result_img_5eb0a8fbc8820.jpg)

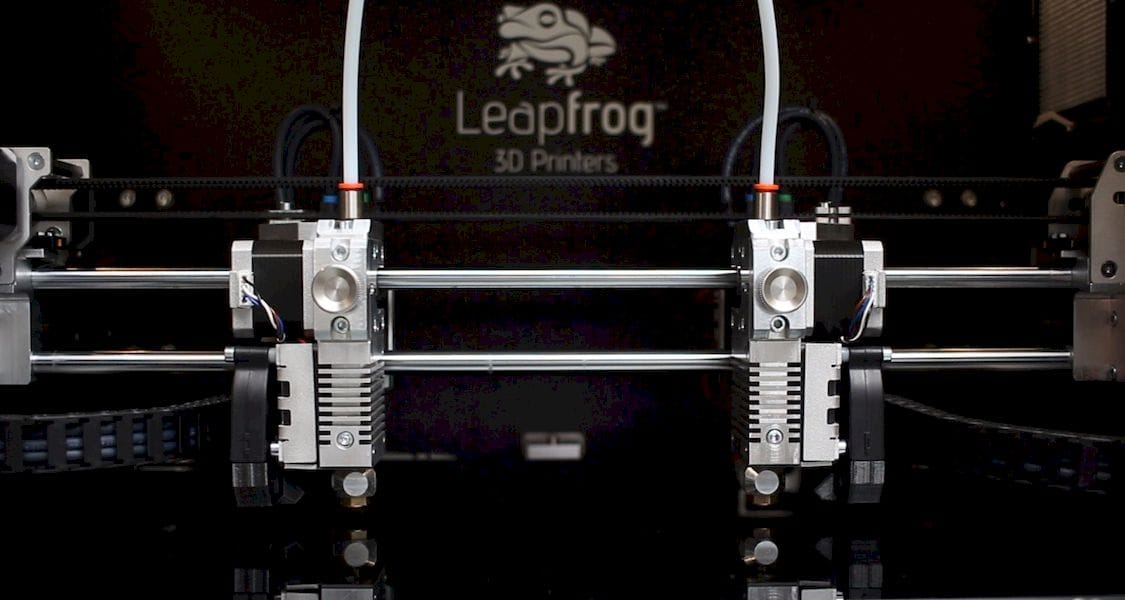

Leapfrog announced some improvements to their flagship 3D printer, the Bolt Pro.

The Netherlands-based company has been marketing the Bolt line for about two years now, and it has been a successful product for the company. The Bolt was a bit of a surprise release at the time, as the company had previously marketed smaller equipment that had roots in the hobbyist market. Of course, back then most startup 3D printer companies were in the same position.

But in recent years many companies in the 3D print space have shifted their operations towards the more profitable professional market. This market includes architects, industrial designers, engineers and prototypers. This market is different in requirements, as they demand higher levels of reliability, better part quality, more consistent results and, most importantly, the ability to 3D print in a much wider range of engineering materials.

Leapfrog’s answer to that demand was the Bolt and Bolt Pro.

However, it’s a very tough market, with countless other companies providing similar equipment and capabilities these days. Companies like Airwolf 3D, Raise 3D, and many others offer competing systems at competitive prices.

That competition may have been what led to the latest improvements in the Bolt system.

So what has changed in the “new” Bolt Pro?

![A new aluminum bed for the Bolt Pro [Source: Leapfrog 3D Printers]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a8fc5eacb.jpg)

They’ve changed the print bed, which is now a solid 6mm slab of perfectly flat aluminum. Leapfrog says it is flat within a micrometer of measurement; that’s pretty flat, at least for 3D printing.

The aluminum bed’s purpose is for heat management. The bed heaters, which are unchanged, as far as we know, will heat the aluminum and the metal slab will distribute the heat far more evenly across its surface. This could increase print reliability as the even heat might help with more consistent adhesion of prints to all parts of the bed. I suppose it could also help distributing heat within the build chamber a bit more evenly, as well. They’ve also made it a bit easier to manipulate the removable glass print plate on top of the aluminum.

![Entirely new industrial cabling in the improved Bolt Pro [Source: Leapfrog 3D Printers]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a8fcabedb.jpg)

They’ve changed out much of the wire harness for the device, replacing it with “high-grade Igus Chainlex CF9 cables”. For machines that are working hard for long years, this could increase the lifespan of the device.

![The new multitouch color control panel on the Bolt Pro [Source: Leapfrog 3D Printers]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a8fd17ddd.jpg)

On the front of the Bolt Pro, you’ll now find a fancy capacitive-touch screen. They say it’s a “multitouch” unit that “supports up to 10 finger touches”. I have no idea why you would ever need to use 10 fingers simultaneously to convey commands to the Bolt Pro, but apparently if that need ever arises, they can handle it. One great feature is that the touchscreen is set at a comfortable angle for easy viewing, unlike a lot of other desktop 3D printers where you have to bend your body to properly see the screen.

Like many 3D printer manufacturers, Leapfrog is experimenting with improved fan ducting. The idea here is that a cooling breeze can quickly freeze soft material before it has a chance to slump, spoiling the print finish. However, early ducts simply blew at the print from one side, leaving the other to a slumpy fate. Newer designs are more sophisticated, attempting to encircle the print with cooling air from a single source. That seems to be what Leapfrog is working on here with a redesigned fan duct.

Leapfrog has also redesigned the support brackets for the machine frame. This should reduce vibrations, which inevitably make their way to the print, where machine jiggles are permanently recorded on the surface of the print. Expect higher quality prints because of this innovation.

Finally they’ve made a change that I wish other 3D printer manufacturers would make: they’ve changed the background color of the build chamber to be more suitable for taking images and videos. All too many machines are near-impossible to properly capture video because of poorly designed visual attributes. That changes with the new Bolt Pro.

The Bolt Pro in its new form is available now, and is priced at €6,499 (USD$7,549).