![An interesting variable lattice automatically generated by Autodesk [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/autodesklatticeov-1_result_img_5eb0a9568d54b.jpg)

I took a look at Autodesk’s latest Netfabb offering and reflected on how it’s changed over the years.

Netfabb was originally not an Autodesk product, but was in fact produced by an independent company in Europe. It’s original functions were to provide basic 3D model repair and job set up: organizing the layout of 3D models on a build plate for optimum printing.

In those days Netfabb also offered a “Basic” version of the software that provided only the repair functions. Many 3D printer operators took advantage of that free product to ensure their 3D models were in good shape for 3D printing, as the simplified slicing software of the day sometimes would get severely confused by broken 3D models. Without repairs, prints could be corrupted or even fail.

But then in 2015 Autodesk arranged a deal with Netfabb to purchase the product, and the acquisition closed in 2016.

The fates of product acquisitions by larger companies are usually an unknown, at least at the beginning. Typically there are only three outcomes:

- The product is integrated into the acquiring company’s product portfolio and helps grow the company.

- The product continues to operate more or less independently and is little different than if it had remained independent.

- The product is starved for cash and languishes, eventually being shut down. Or perhaps it’s shut down immediately if the acquirer sees that as a strategic move, much to the anger of the product’s users.

Fortunately for us, Autodesk has chosen the first option: full integration. In fact, Autodesk has set up their powerful 3D modeling tool Fusion 360 to directly feed Netfabb for near-instant 3D printing job setup.

![Another variable lattice automatically generated by Autodesk [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/autodesklatticeov2-1_result_img_5eb0a9571c303.jpg)

Today Autodesk Netfabb is a highly sophisticated product that provides a great deal of function for advanced 3D printer operators. While the product still includes the fundamental functions of 3D model repair and job setup, they’ve added a number of very powerful functions.

- Advanced automated packing can take a series of separate 3D models or model copies and “Tetris” them into a build volume in the most efficient manner possible, with far more smarts than one could manage manually.

- Netfabb can automatically generate complex support structures optimized for a number of popular industrial 3D printers. This is of particular interest for those using 3D metal printers, which require significant attention due to thermal action throughout the print and support structures during printing.

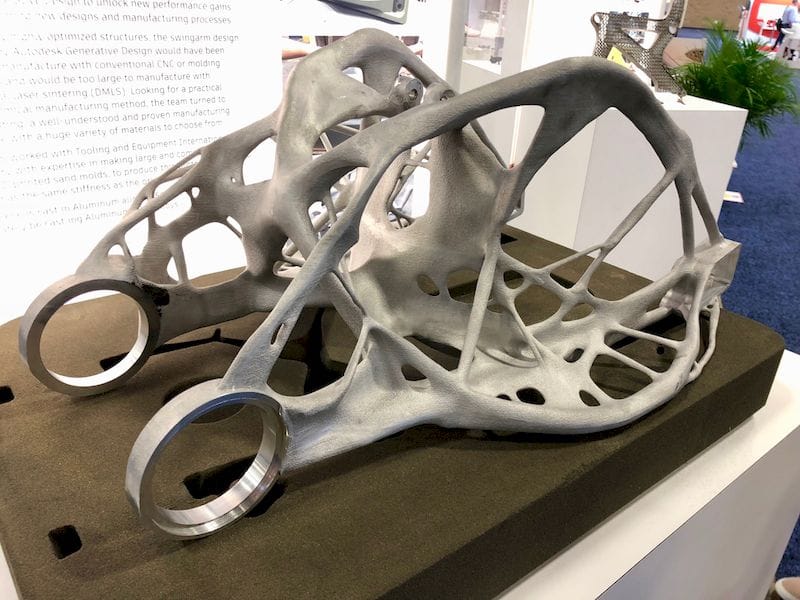

- Lattice generation is now possible and automatic, as seen in the image at top. This feature enables very easy creation of lightweight parts suitable for several industries.

- Toolpaths can be optimized in a number of ways with advanced tools that permit tweaking to ensure the print will proceed with the best chance of succeeding and providing the best results.

- Scripting capabilities can add even more automation that’s specifically designed to handle your particular workflow.

Autodesk also now offers a Netfabb Simulation version that can provide important simulation of complex 3D print jobs that permit advanced checking before committing to very expensive job runs. Some of the aspects of simulation include:

- Small scale simulation- PRM generation

- Part scale simulation

- Simulation of entire build plate

- Deformation prediction and compensated shape export

- Support failure prediction

- Recoater interference detection

- Heat treatment

- Part and support parameters

- Distortion and stress after removal from build plate

- Hot spots and lack of fusion

- Directed energy deposition process simulation

Sales of Netfabb are divided into several versions that match typical user requirements:

- Netfabb Standard provides 3D model editing and repair, job setup, measurements. It’s available for a subscription price of USD$30 per month with other subscription pricing options available.

- Netfabb Premium includes Standard features and adds 3D automatic job packing for those operating large volume powder equipment, automatic lattice generation, far more complex support structure generation, and the ability to interface with 3D metal printers. It’s available for a subscription price of USD$515 per month.

- Netfabb Ultimate has all the features available, including scripting, advanced toolpathing, more complex lattice generation and local processing for faster results. It also bundles in a full Autodesk Fusion 360 subscription that permits generative design. Ultimate is priced at USD$1,600 per month.

- Netfabb Simulation includes the simulation features described above and you’ll have to contact Autodesk for special pricing.

And if you’re wondering, that free version of Netfabb for basic repairs is still available, but it’s hidden: you must download the full trial of Netfabb, and if you choose not to proceed with a paid version, your trial will automatically revert into what was once known as “Basic”. However, the tool is now only available on the Windows platform, so Mac and Linux users must seek free repair options elsewhere.

Via Autodesk