![Incorporating voids to strengthen 3D printed parts [Source: RepRap]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a1b20bff5.jpg)

Adrian Bowyer proposes a very unusual approach for strengthening 3D printed parts: embedding voids.

At first this makes no sense, as voids should make a part weaker, not stronger. But in fact this is not the case, according to Adrian Bowyer, writing at RepRap. Bowyer, if you don’t know, is the person behind the concept of devices that self-replicate, which led to the RepRap movement and, by extension, the diverse desktop 3D printing world of today.

Bowyer’s concept requires the understanding that 3D printed parts are very rarely produced with 100% infill. In fact, most parts are 3D printed with less than 50% infill. Most of the time this amount of infill is more than sufficient for the job, but in some cases involving mechanical stress the print operator may choose to up the infill percentage to strengthen the part.

But that is expensive in terms of material, and the portions of the part that actually undergo stress would be the only segments that really require beefing up, thus wasting the extra infill on “dead” segments.

Bowyer noted that some have strengthened 3D printer filament by introducing fibers into the thermoplastic mix. Usually these fibers are carbon fiber or perhaps glass, but in any case fibers provide some extra strength in the extruded material.

But he devised a way to achieve fiber-like strength without using any actual fibers. Here’s how it works:

Consider the case of a typical part being 3D printed with, say, 20% infill. This would result in an interior that contains a regular pattern of structures made from the same material as the rest of the print. The interior of the model that comprises the infill is simply a solid segment of the original 3D model.

Now imagine if that solid interior was peppered with an arrangement of cylindrical voids. When that 3D model is sliced, the non-void volumes would still be made into 20% infill, but the cylindrical voids would be treated, as they should, as external surfaces. They’d receive the specified number of perimeters and shells that the exterior surface receives.

This introduces more material to the interior of the 3D model, beyond the expected 20%. But that extra material is arranged in long cylinders that resemble gigantic fibers. These add significant strength the part merely by tweaking the model and not making any changes to the material, function of the part, or other print parameters.

But how could these cylindrical voids be arranged? I would expect that they would offer different types of strengthening depending on their orientation and the function of the part.

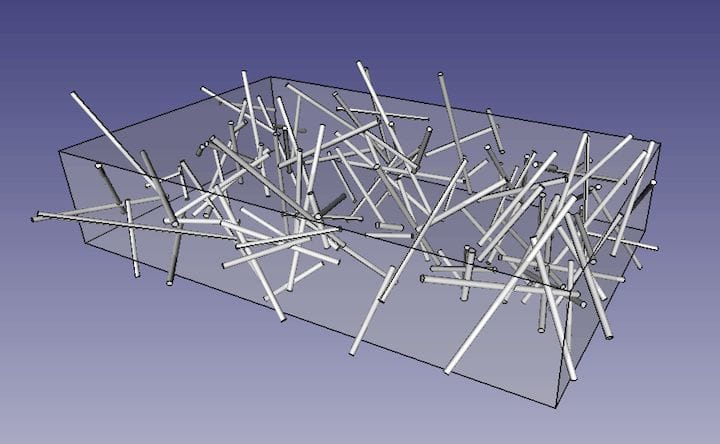

Bowyer experimented by generating a random arrangement of them with a script, and indeed found that the resulting 3D printed part was stronger.

![Manual void reinforcements in a 3D printed part [Source: RepRap]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a1b266e09.jpg)

In a more specific test, Bowyer manually inserted cylindrical voids into known high-stress zones of a particular part. Testing of the printed part showed a 54% improvement, as seen in this chart:

![Relative part strength: The blue line is the control beam with no reinforcement; the orange is the beam with the thin cylindrical voids.[Source: RepRap]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a1b2aa950.jpg)

This is a very interesting approach, and one that could easily be implemented by hand using almost any 3D CAD tool. But what is of more interest to me is that the technique could be married to more sophisticated model generation systems.

Imagine a CAD tool where you design a part in the usual manner, but then specify the specific mechanical stress scenario, as is done in some simulation tools. But instead of performing a simulation, the tool could automatically generate an arrangement of cylindrical voids for that 3D model that would best address the mechanical stress scenario.

This does not sound particularly difficult to implement, given that simulation tools are already doing most of the heavy lifting. I would not be surprised to see this feature emerge on several platforms soon.

Via RepRap Ltd

It turns out there are indeed some 3D models in their archive, but it takes a bit of detective work to find them.