![[Image: ZMorph]](https://fabbaloo.com/wp-content/uploads/2020/05/ZMorph_lifestyle_10a_img_5eb09502b8b40.jpg)

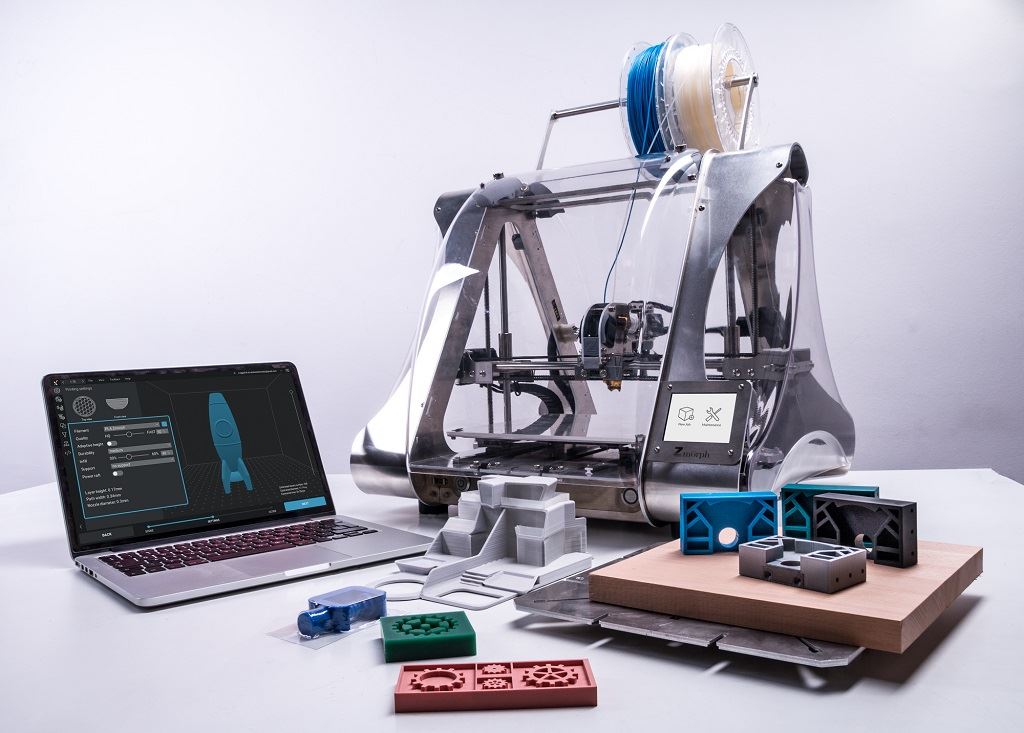

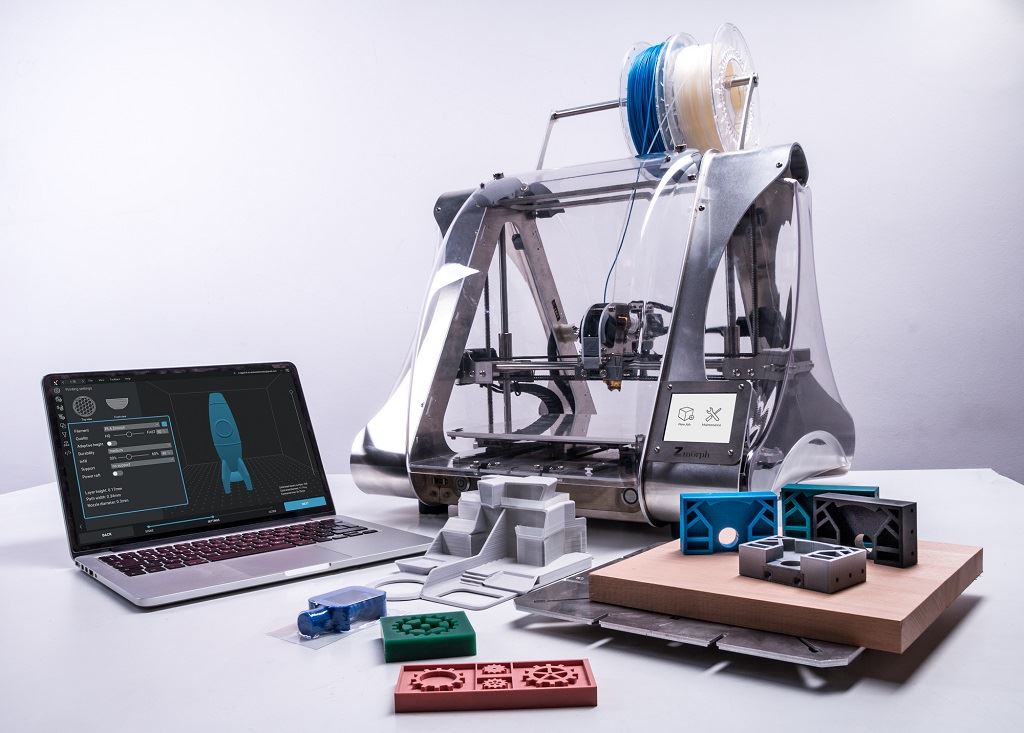

3D printing was once considered science-fiction, but in the last couple of decades, it’s become not only science-fact but also something the average hobbyist can have on in their workshop. It also appears in nearly every industry around the globe, offering far-reaching implications for many businesses.

Let’s take a look at a few of the most impressive 3D printing innovations of the last five years and see how much the industry has changed since it began.

1. Color 3D Printing

![A full color dragon 3D print made by the new da Vinci Color mini [Source: XYZprinting]](https://fabbaloo.com/wp-content/uploads/2020/05/da2Bvinci2Bcolor2Bmini2Bdragon_result_img_5eb0950325da1.jpg)

You can create nearly anything with a 3D printer, but with traditional machines, you’re usually relegated to a single color at a time. While there are still few options for full-color 3D printing, an innovation by XYZprinting introduced the first full-color print in a desktop printer. The da Vinci Color Mini FDM works just like an inkjet by combining magenta, cyan and yellow inks with a color-absorbing filament. Each shade is custom mixed right before the layers are printed, creating prints without the hassle of having to change the filament each time you want a new color. On the more industrial side are a long-time offering from 3D Systems, as well as more recent advanced introductions from Stratasys, Mimaki, HP, and Rize.

2. Recycled Paper Printing

Most 3D printers use a plastic filament to create their masterpieces, but they don’t have to anymore. One designer has created a way to use something more sustainable as a printing medium — paper pulp. It uses recycled paper combined with a natural binder to create the same sort of layers you can see with a plastic filament, only made out of paper. While it might not look as clean as other printed materials, it is much more sustainable and gives the designs a bit of rustic personality that you might not find elsewhere.

3. 3D Printing Food

![Barilla-Sponsored 3D Printed Pasta Competition [Source: Spadellatissima ]](https://fabbaloo.com/wp-content/uploads/2020/05/Pasta1_img_5eb095037b471.jpg)

While we’re not quite up to the level of Star Trek-esque replicators that can create food out of nothing, 3D printers that make unique foodstuffs are starting to become more common. In 2014, these printed snacks were primarily sugar-based confections, but as the technology has advanced, these 3D printers have evolved to the point where they can create both sweet and savory items. While it isn’t suited to make every type of food, it excels in things like pasta, cookies and custom pizzas.

4. 3D Printed Insoles

![Cryoscan3D in action [Image: Fuel3D]](https://fabbaloo.com/wp-content/uploads/2020/05/cryoscan3d_img_5eb09503d30a4.jpg)

Custom orthotics and insoles for shoes are ideal for helping prevent or heal foot pain, but they are designed to be one-size-fits-all, which doesn’t always work — everyone’s feet are different. 3D printed orthotics and insoles have begun to emerge, based on detailed digital scans of each person’s feet. These orthotics can be customized for each individual, depending on their needs.

5. Ceramic 3D Printing

![Ceramic 3D Printer [Image: Olivier van Herpt ]](https://fabbaloo.com/wp-content/uploads/2020/05/3d-printer-ceramics_img_5eb095045a3f4.jpg)

There are a number of different materials that are making an appearance in the 3D printing industry. One of the most intriguing emerging mediums is ceramic. One designer created a 3D print extruder that uses clay, producing items that are up to 90 centimeters tall and 60 centimeters in diameter. These vases and other clay items still need to be fired once they’re complete, but that doesn’t dim the exciting discovery that they can be molded through a 3D printer.

The Future of 3D Printing

3D printing is becoming one of the most exciting advancements of the 21st century. With computer design and a printer filled with one of many different materials that can be fed through an extruder, laid on a powder bed, or polymerized in a vat, you can createnearly anything. Designers are making everything from prosthetic limbs to tools for astronauts with nothing more than a design and a printer, which would have boggled the mind only a few short years ago.

The technology is evolving, and only time will tell what materials, mediums or creations will come next.