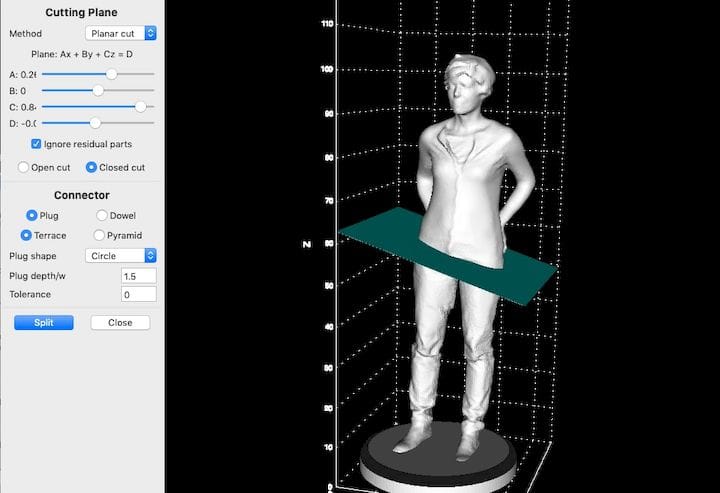

![Chopping up a 3D model in LuBan [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0970671511.jpg)

LuBan is a software tool to greatly assist when a very large 3D print is required.

One of the persistent questions I always receive when talking to newbies about a 3D printer is this: “How Big Can It Print???”

There are two answers. The first answer is simply the build volume of the device. But the second answer is more profound: The build volume doesn’t matter because you can split your part into multiple sections and print them separately. Assemble them later to produce an object larger than the original build volume.

Thus, the size of a printed object has nothing to do with the build size of a specific machine.

That’s all well and good, but how, exactly, does one do this?

On a simple model, one could use any of several 3D modeling tools to chop a design in half, say. These two halves could be maximized to fit in the build volume and then glued together after printing. Voilà, we have “doubled” the build size, in a way.

But wait, there are problems.

One is alignment. If you simply chop a 3D model in half, how do you know how the two pieces should be aligned when glued? The answer is to insert some holes and pegs into the two models’ designs. Then there is only one way they fit together.

That is fairly easily done in most 3D modeling tools, but will take a few minutes to do.

Now you have another problem. What if your large 3D print is so big that it requires dozens, or perhaps a hundred separate parts? Are you going to 3D model pegs and holes on each part? That could take a considerable amount of time. Even worse, where do you put the pegs if a piece has more than two sides joining others? Or four? If you do this wrong, then you will not be able to assemble the parts!

![3D printed parts to be assembled [Source: LuBan]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb097069d2ee.jpg)

There’s yet another challenge: keeping track of the parts. If you have, say, 50 pieces printed, how do you know which one is which? In what order do you assemble them?

I know what you are thinking now: “If there’s more than two or three pieces, I give up!”

It turns out you don’t have to give up. There is a software solution for this dilemma, and it’s called LuBan.

Developed by researchers at MIT and Singapore University of Technology and Design, this tool offers a number of very useful and practical features that can transform a 3D model, including automatically splitting it up into print-sized chunks.

The software allows you to import an existing 3D model and perform a number of operations on it. Many of them are directed towards laser cutting. For example, you could transform a 3D model into a series of stackable flat pieces that could be laser cut and assembled into a pancake-style version of the object.

Those functions are certainly very useful to laser operators, but I’m specifically interested in the mesh split function, which allows you to intelligently chop a 3D model into assemble-able pieces.

![3D model plane cutting parameters in LuBan [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/luban-cutting-parameters_result_img_5eb09706c424d.jpg)

LuBan’s split mesh editor shows the 3D model in a rotatable 3D window into which you can add cutting planes wherever you like. You can add multiple planes to divide a 3D model into correctly sized portions.

Each piece can have attachment points automatically generated; these are the pegs and holes I mentioned above. However, LuBan allows significant control over the attachment generation. You can specify plug, dowel, terrace or pyramid shapes. You can specify the depth required as well as geometric tolerance.

![Attachment plugs for 3D prints [Source: LuBan]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09706e8f3d.jpg)

LuBan is intelligent as it can automatically detect “residual parts”, as shown here. This feature alone will vastly simplify this work over manual efforts.

![Intelligent handling of residual objects from a 3D plane cut [Source: LuBan]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb097071dd5a.jpg)

Once generated, LuBan provides an assembly guide by numbering the parts and including an assembly sequence. This feature is critical to success when 3D printing large composite objects.

LuBan is available for Windows (32 and 64 bit) as well as MacOS. There is a charge for the software, however: It’s US$30 per year, which also requires an internet connection for date validation, or a permanent license for US$150 that can be used offline. Trial licenses are available upon request.

If you are considering a large multi-part 3D print project, I think you might want to have a good look at LuBan.

Via LuBan

MiniFactory’s new software produces a very useful report for each 3D print that may be important for clients. We had a close look at one.