Slant3D has re-invented the ubiquitous 3D printer filament spool, but for some reason it’s not round.

Spools come in all kinds of sizes, shapes and designs; I should know, I have most of them here at the lab. Some are quite usable, while others are frustratingly difficult. Some offer handy well-positioned holes to secure the end of the filament, and others are made from recycled material. Some you even 3D print yourself.

But they are all, without exception, round.

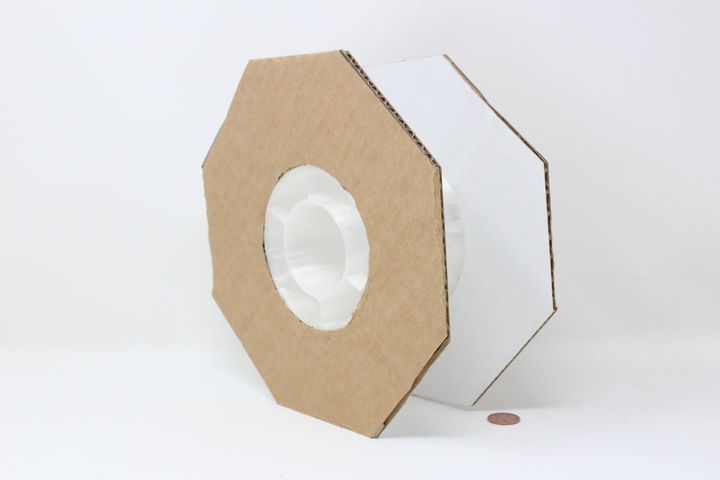

That’s why I was quite surprised to see Slant3D’s take on a new spool, which they call the “SlantSpool”. It’s a combination of white-stamped cardboard and a 3D printed hub, but the unique feature is that the cardboard walls are cut in an octagon shape.

There have been many new takes on spools, but why did Slant3D want to make such a radically different design? They explain:

“They [the standard MC-008W spools] are expensive to ship, nearly impossible to recycle, and in production they are not efficient or easy. Not to mention that new covid restrictions and tariffs on the Chinese-made spool have increased so that they have become expensive. But it is what there is.”

What’s behind the design of the SlantSpool? Again, they explain further:

“The SlantSpool V3 is modeled off the MC-008W spool. The core interface is dimensionally identical so that it can fit on existing fixtures. The outer cardboard flanges are stamped from white-coated cardboard to prevent dust contamination of filament. The entire spool is half the weight of traditional MK-008W spools so shipping costs are lower both from Slant 3D and to customers, saving filament suppliers thousands of dollars.

We have also adjusted the design to make use simpler. The Core has 4 primary anchoring holes for the filament that are over-large to make starting the spool easier on the winder machine. And the hole is curved to ensure that filament is not kinked at the end causing a jam in the 3D Printer when it is used.”

It turns out Slant3D is manufacturing the hub of the spool on the extensive 3D print farm, which makes it pretty straightforward to produce whole spools. They believe the cost of the hubs is about the same as injection molded equivalents, and are offering them to others as a product. Slant3D will even customize the spools with client logos, or even modify the hub design somewhat.

The advantage to the spool is that it is about half the weight of the standard spool, which can certainly help with shipping costs. The SlantSpool is also entirely recyclable.

But, I keep thinking, “It’s Not Round!”

Are round spools necessary? While there are many spool holders that rely solely on the hub, there are others that require a round spool edge for mounting.

Slant3D was questioned about the clear lack of roundness in the SlantSpool, and Slant3D’s Gabe Bentz replied:

“But the vast majority use the hub. And the octagon flanges allow the spool to be placed on a shelf or table without danger of it rolling off or away. Stacking them on their side is more cumbersome than on edge on the flange.”

This is in fact true: most 3D printers require a hub for spool mounting. However, I did not consider the idea of vertical stacking until Bentz brought it up.

I think this could be a very good idea. Most of the time spools are left lying down, where the filament can get tangled if it is not properly secured — or breaks on its own.

A vertically stored spool would not have these problems. And yes, it won’t roll away either.

Is the octagonal SlantSpool something you would use? What are your thoughts?

Via Slant3D