In an interesting short video, 3D print service Qualified3D demonstrates a method for producing mass customized objects.

Qualified3D is a new Michigan-based advanced manufacturing service that currently offers quite a list of capabilities:

- Multi Jet Fusion (MJF)

- 3D Printed Silicone

- Micro Stereolithography

- Stereolithography (SLA)

- Freeforming (APF)

- Micro Metal Laser Sintering

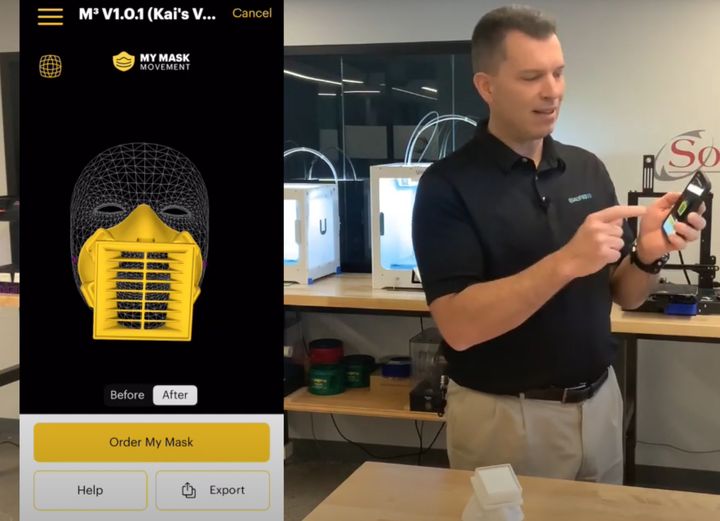

In the video, they demonstrate how an app can almost instantly capture a buyer’s facial geometry to create a custom 3D model of a respirator. Because of the use of the unique geometry, the resulting respirator will fit the wearer perfectly.

Here’s the video:

What’s fascinating about this is the speed of the operation: the product is generated almost instantly, likely faster than the buyer can react. Then Qualified3D offers a push button to immediately send it for production at their manufacturing service.

That’s a way to generate more service business, but it’s also wonderful demonstration of what is now possible.

The technological breakthrough here is the introduction of facial scanning by mobile devices. While originally intended for security purposes, many have developed apps that leverage the same technology for other purposes. One common application has been to create kind of 3D scanner app to capture objects and sometimes people in the vicinity. However, many of these apps are constrained one way or another in how you can use the captured 3D models.

What Qualified3D has done here is to link it all together to provide a complete end-to-end consumer experience, and a rapid experience it is.

I’ve seen attempts at this previously, such as Materialise’s work on a 3D booth for generating eyeglass designs. However, that required a specialized kiosk, and as such would be of limited ability to be distributed.

Imagine, however, if that same type of functionality was put into an app that was deployable to literally millions of people’s mobile devices. How fast could you deploy kiosks? Or how fast can you deploy an app? I think you get the difference here, and it’s huge.

If this technology works for a respirator, then it could also work for other personalized items. Eyeglasses could certainly be part of this sequence, as could masks of other types.

The process would not necessarily be limited to facial objects, either, as the 3D depth cameras on mobile devices are perfectly suitable for capturing other parts of the body, too.

For example, if a mobile device can be used to measure the size of a room, as is done with several construction-oriented apps, it could also measure a person. This opens up the possibility of using the same approach for custom-made clothing. Like Materialise’s eyeglass solution, these apps could simulate the clothing on the buyer’s image — maybe even in 3D.

One of the big applications for this concept might be in footwear. Just like the face, feet could be scanned in 3D and mapped to base designs that could be dynamically modified just like the respirator to produce custom-fit footwear.

Once this concept catches on, it might become commonplace, as people would surely want custom products over mass produced items, as long as the price was right.

Via Qualified3D