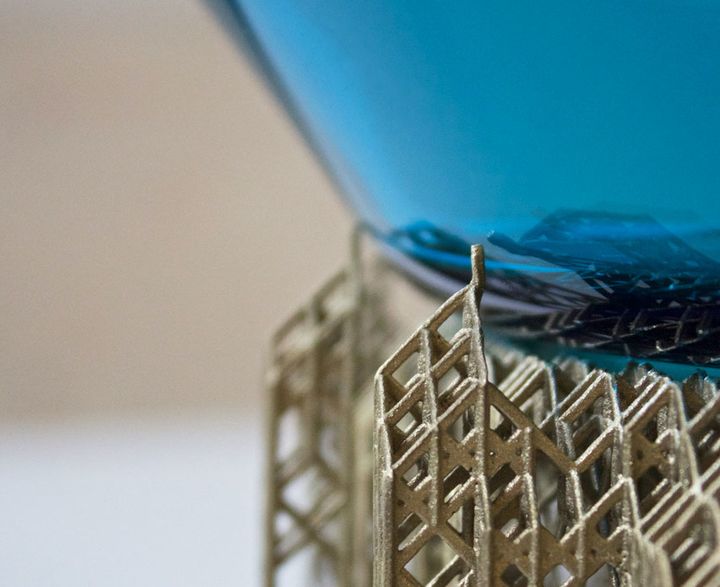

This week’s selection is the Skafaldo Bowl & Side Table by Unfold.

Unfold is a Belgian design firm that has consistently produced utterly fascinating 3D printed designs for many years. Many of their pieces are quite unusual and explore areas of 3D printing rarely seen, and that is certainly the same with the Skafaldo Bowl & Side Table.

This two-piece work features 3D printed structures that support a bowl and a tabletop. However, the design of those structures is quite a bit different from the usual method of making an object.

Unfold explains:

“Skafaldo is the result of a collaboration between design studio Unfold and additive manufacturing specialist Materialise in which automatically generated support structures — a feature normally discarded in the process — becomes the focal point of two new pieces.”

Hold on, this design IS a support structure? Apparently so!

They continue:

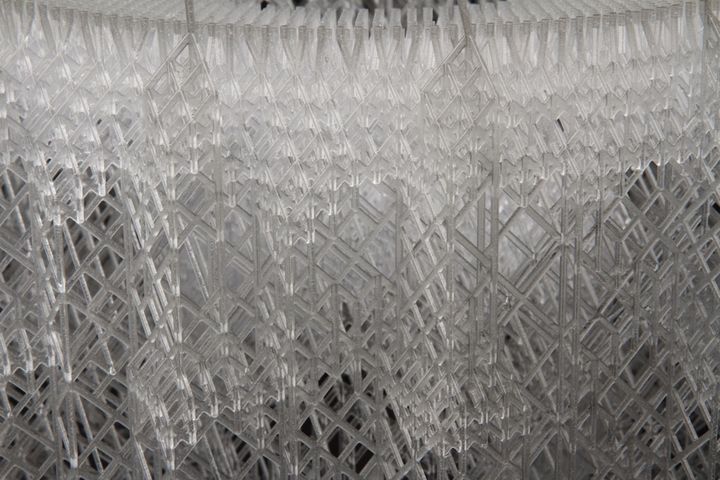

“Support structures are the black sheep of 3D Printing. While necessary to support complex objects with overhangs and shallow angles, they are hardly meant to look beautiful, let alone become a work of art in their own right. Unfold was intrigued by their almost gothic appearance, reminiscent of a cathedral or the hyper functionality of industrial architecture apparent in the work of Hilla and Bernd Becher.

Fascinated by the seeming randomness and unpredictability of the support structure generated by Materialise e-Stage, Unfold ended up making almost 100 different designs to trigger the different structures generated by the program.”

Evidently these structures were literally generated as support structures, but used after 3D printing as the final object. This is done by creating a Model object that causes the slicing system to generate the desired support structure/object.

Normally we all throw support structures away, sometimes with vengeance if they were difficult to remove. Here the support structures are in fact the goal of the 3D print job.

Materialise was likely one of the best options to produce these prints, as they operate stereolithography systems that have massive build volumes, easily able to accommodate the bowl and side table mounts.

However, when printed the objects are resin-like in appearance. Here you can see an image of the prints before finishing work was applied, and they appear quite clear.

However, post-processing in this case was to use the 3D print as a positive mold for a bronze casting, done by a third party.

The results are quite stunning, and after seeing this I suspect you will be a bit more careful with your support structures.

Via Unfold